What is Micro Machining Tool - Global Market?

Micro machining tools are specialized instruments used for creating extremely small and precise components, often at the micro or even nano scale. These tools are essential in industries where precision is paramount, such as electronics, medical devices, and aerospace. The global market for micro machining tools is driven by the increasing demand for miniaturized products and components. As technology advances, the need for smaller, more efficient, and more precise parts grows, pushing the boundaries of what these tools can achieve. Micro machining tools include a variety of devices such as micro end mills, micro CNC drills, and micro reamers, each designed for specific tasks and materials. The market is characterized by continuous innovation, with manufacturers striving to improve the accuracy, speed, and versatility of their tools. This market is also influenced by the growing trend of automation and the integration of advanced technologies like AI and IoT, which enhance the capabilities of micro machining tools. As industries continue to evolve, the demand for these tools is expected to rise, making the global market for micro machining tools a dynamic and rapidly growing sector.

Micro End Mills, Micro Cnc Drills, Micro Reamers, Other in the Micro Machining Tool - Global Market:

Micro end mills are a type of micro machining tool used for cutting and shaping materials with high precision. These tools are essential in industries that require intricate designs and tight tolerances, such as electronics and medical devices. Micro end mills are typically made from high-speed steel or carbide, materials known for their durability and ability to maintain sharp edges. They come in various shapes and sizes, each designed for specific applications, such as slotting, profiling, or contouring. The global market for micro end mills is driven by the increasing demand for miniaturized components and the need for high-precision machining. Manufacturers are continuously innovating to improve the performance and longevity of these tools, incorporating advanced coatings and geometries to enhance their cutting capabilities. Micro CNC drills, on the other hand, are used for creating small, precise holes in various materials. These drills are essential in industries like electronics, where they are used to create holes for circuit boards and other components. The global market for micro CNC drills is driven by the growing demand for electronic devices and the need for high-precision drilling. Manufacturers are focusing on developing drills with improved accuracy, speed, and durability to meet the demands of modern industries. Micro reamers are another type of micro machining tool used for finishing holes with high precision. These tools are essential in industries that require tight tolerances and smooth finishes, such as aerospace and automotive. The global market for micro reamers is driven by the increasing demand for high-precision components and the need for efficient finishing processes. Manufacturers are continuously innovating to improve the performance and longevity of these tools, incorporating advanced materials and coatings to enhance their cutting capabilities. Other micro machining tools include a variety of specialized instruments designed for specific applications, such as micro lathes, micro grinders, and micro EDM machines. These tools are essential in industries that require high-precision machining and are driven by the increasing demand for miniaturized components and the need for efficient manufacturing processes. The global market for these tools is characterized by continuous innovation and the integration of advanced technologies to enhance their capabilities.

Aerospace, Automotive, Chemical, Other in the Micro Machining Tool - Global Market:

Micro machining tools play a crucial role in various industries, including aerospace, automotive, chemical, and others. In the aerospace industry, these tools are used to create small, precise components that are essential for the performance and safety of aircraft. The demand for lightweight and high-performance materials in aerospace drives the need for micro machining tools that can work with advanced materials like titanium and composites. These tools are used to create intricate designs and tight tolerances, ensuring the reliability and efficiency of aerospace components. In the automotive industry, micro machining tools are used to create small, precise components that are essential for the performance and efficiency of vehicles. The demand for lightweight and fuel-efficient vehicles drives the need for micro machining tools that can work with advanced materials like aluminum and composites. These tools are used to create intricate designs and tight tolerances, ensuring the reliability and efficiency of automotive components. In the chemical industry, micro machining tools are used to create small, precise components that are essential for the performance and efficiency of chemical processes. The demand for efficient and reliable chemical processes drives the need for micro machining tools that can work with advanced materials like stainless steel and ceramics. These tools are used to create intricate designs and tight tolerances, ensuring the reliability and efficiency of chemical components. Other industries that use micro machining tools include electronics, medical devices, and telecommunications. In these industries, micro machining tools are used to create small, precise components that are essential for the performance and efficiency of products. The demand for miniaturized and high-performance products drives the need for micro machining tools that can work with advanced materials and create intricate designs and tight tolerances. The global market for micro machining tools is characterized by continuous innovation and the integration of advanced technologies to enhance their capabilities.

Micro Machining Tool - Global Market Outlook:

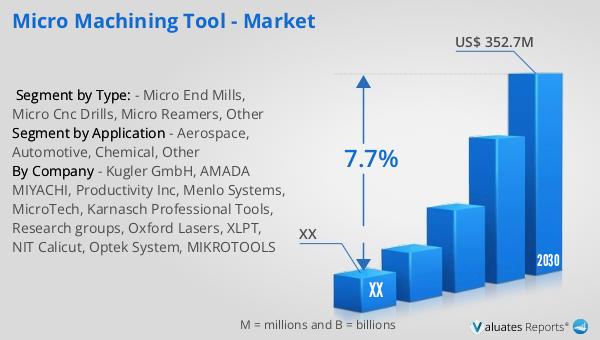

The global market for micro machining tools was valued at approximately $197 million in 2023. This market is projected to grow significantly, reaching an estimated size of $352.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 7.7% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for precision tools across various industries, driven by technological advancements and the need for miniaturized components. The market's expansion is fueled by the continuous innovation in micro machining technologies, which enhances the efficiency and capabilities of these tools. As industries such as aerospace, automotive, and electronics continue to evolve, the demand for micro machining tools is expected to rise, contributing to the market's growth. The integration of advanced technologies like AI and IoT in micro machining tools further boosts their adoption, as these technologies enhance the precision and efficiency of machining processes. The global market for micro machining tools is dynamic and rapidly growing, with manufacturers focusing on developing innovative solutions to meet the evolving needs of industries. This growth trajectory highlights the importance of micro machining tools in modern manufacturing and their role in driving technological advancements across various sectors.

| Report Metric | Details |

| Report Name | Micro Machining Tool - Market |

| Forecasted market size in 2030 | US$ 352.7 million |

| CAGR | 7.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kugler GmbH, AMADA MIYACHI, Productivity Inc, Menlo Systems, MicroTech, Karnasch Professional Tools, Research groups, Oxford Lasers, XLPT, NIT Calicut, Optek System, MIKROTOOLS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |