What is Metalworking Equipment - Global Market?

Metalworking equipment refers to a broad range of machinery used in the process of shaping and forming metal into desired forms and structures. This equipment is essential in various industries, including automotive, construction, aerospace, and manufacturing, as it allows for the precise cutting, shaping, and finishing of metal components. The global market for metalworking equipment encompasses a wide array of machines, each designed for specific tasks and applications. These machines include lathes, milling machines, grinding machines, drilling machines, and saw machines, among others. The demand for metalworking equipment is driven by the need for high-quality, durable metal products in various sectors. As industries continue to evolve and innovate, the metalworking equipment market is expected to grow, with advancements in technology leading to more efficient and versatile machines. The market is characterized by a mix of established manufacturers and new entrants, all competing to provide the most advanced and reliable equipment to meet the diverse needs of their customers. The global market for metalworking equipment is a dynamic and competitive landscape, with ongoing developments in technology and manufacturing processes shaping its future.

Lathe Machines, Milling Machines, Grinding Machines, Drilling Machines, Saw Machines, Others in the Metalworking Equipment - Global Market:

Lathe machines are a fundamental component of the metalworking equipment market, known for their ability to rotate a workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation. These machines are essential for creating symmetrical objects and are widely used in industries that require precision and efficiency. Milling machines, on the other hand, are designed to remove material from a workpiece by feeding it against a rotating cutter. They are versatile and can perform a range of operations, including drilling, slotting, and cutting gears. Grinding machines are used to finish workpieces to a high degree of accuracy and surface quality. They employ an abrasive wheel as the cutting tool, which is ideal for achieving fine finishes and precise dimensions. Drilling machines are specifically designed to create holes in metal workpieces. They come in various types, including bench, pillar, and radial drilling machines, each suited for different applications and levels of precision. Saw machines are used to cut metal into specific shapes and sizes. They include band saws, circular saws, and hacksaws, each offering unique advantages depending on the material and desired cut. Other metalworking equipment includes presses, which are used to shape or cut metal by applying pressure, and CNC machines, which offer automated control for complex and precise operations. The global market for metalworking equipment is diverse, with each type of machine playing a crucial role in the production of metal components. As technology advances, these machines are becoming more sophisticated, offering greater precision, efficiency, and versatility to meet the evolving needs of various industries.

Automotive, Construction, Marine, Others in the Metalworking Equipment - Global Market:

Metalworking equipment plays a vital role in several key industries, including automotive, construction, marine, and others. In the automotive industry, metalworking equipment is used to manufacture a wide range of components, from engine parts to body panels. The precision and efficiency of machines like lathes and milling machines are crucial for producing high-quality automotive parts that meet stringent safety and performance standards. In the construction industry, metalworking equipment is used to fabricate structural components, such as beams, columns, and trusses. These machines enable the production of durable and reliable metal structures that form the backbone of modern buildings and infrastructure. In the marine industry, metalworking equipment is essential for constructing ships and other marine vessels. The ability to shape and form metal into complex structures is critical for ensuring the strength and integrity of these vessels, which must withstand harsh marine environments. Other industries that rely on metalworking equipment include aerospace, where precision and reliability are paramount, and manufacturing, where efficiency and versatility are key. The global market for metalworking equipment is driven by the diverse needs of these industries, with each sector requiring specific machines and capabilities to meet their unique demands. As industries continue to innovate and evolve, the demand for advanced metalworking equipment is expected to grow, with new technologies and processes shaping the future of this dynamic market.

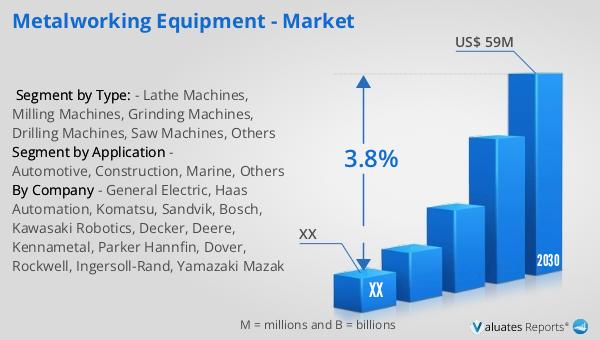

Metalworking Equipment - Global Market Outlook:

The global market for metalworking equipment was valued at approximately US$ 45 million in 2023. This market is projected to grow steadily, reaching an estimated size of US$ 59 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. The steady increase in market size reflects the ongoing demand for metalworking equipment across various industries, driven by the need for high-quality, durable metal products. As industries such as automotive, construction, and marine continue to expand and innovate, the demand for advanced metalworking equipment is expected to rise. This growth is also supported by technological advancements in metalworking machinery, which are leading to more efficient and versatile machines. The market is characterized by a mix of established manufacturers and new entrants, all competing to provide the most advanced and reliable equipment to meet the diverse needs of their customers. As the global market for metalworking equipment continues to evolve, it presents significant opportunities for growth and innovation, with ongoing developments in technology and manufacturing processes shaping its future.

| Report Metric | Details |

| Report Name | Metalworking Equipment - Market |

| Forecasted market size in 2030 | US$ 59 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | General Electric, Haas Automation, Komatsu, Sandvik, Bosch, Kawasaki Robotics, Decker, Deere, Kennametal, Parker Hannfin, Dover, Rockwell, Ingersoll-Rand, Yamazaki Mazak |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |