What is Global High-Speed Air-Flow Powder Sub-Filling Production Line Market?

The Global High-Speed Air-Flow Powder Sub-Filling Production Line Market is a specialized segment within the broader industrial machinery market. This market focuses on the production lines that utilize high-speed air-flow technology to fill powders into various containers. These production lines are designed to handle a wide range of powdery substances, ensuring precision and efficiency in the filling process. The technology is particularly beneficial for industries that require high-speed operations and accuracy, such as pharmaceuticals, food, and chemicals. The use of air-flow technology minimizes the risk of contamination and ensures that the powders are filled uniformly, which is crucial for maintaining product quality. The market for these production lines is growing due to the increasing demand for automation and efficiency in manufacturing processes. Companies are investing in these advanced systems to enhance their production capabilities and meet the stringent quality standards required in various industries.

Seamless Filling, Non-Seamless Filling in the Global High-Speed Air-Flow Powder Sub-Filling Production Line Market:

Seamless filling and non-seamless filling are two critical aspects of the Global High-Speed Air-Flow Powder Sub-Filling Production Line Market. Seamless filling refers to a process where the powder is filled into containers without any interruptions or gaps. This method is highly efficient and ensures that the product is evenly distributed within the container. Seamless filling is particularly important in industries like pharmaceuticals and food, where precision and hygiene are paramount. The technology used in seamless filling systems often includes advanced sensors and control mechanisms that monitor the filling process in real-time, ensuring that each container is filled to the exact required level. On the other hand, non-seamless filling involves a process where there may be slight interruptions or variations in the filling process. While this method may not be as precise as seamless filling, it is still widely used in industries where absolute precision is not as critical. Non-seamless filling systems are generally more cost-effective and easier to maintain, making them a popular choice for smaller operations or for products where minor variations in filling levels are acceptable. Both seamless and non-seamless filling systems have their own set of advantages and are chosen based on the specific needs of the production line. The choice between the two often depends on factors such as the type of powder being filled, the required production speed, and the level of precision needed. In the Global High-Speed Air-Flow Powder Sub-Filling Production Line Market, manufacturers offer a range of options to cater to the diverse needs of different industries. Advanced seamless filling systems are equipped with features like automatic cleaning and sterilization, which are essential for maintaining hygiene standards in the pharmaceutical and food industries. These systems also often include sophisticated software that allows for easy monitoring and control of the filling process. Non-seamless filling systems, while simpler, are designed to be robust and reliable, ensuring consistent performance even in demanding production environments. Both types of systems play a crucial role in enhancing the efficiency and productivity of manufacturing processes, making them indispensable tools in the modern industrial landscape.

Pharmaceutical Industry, Food Industry, Chemical Industry, Others in the Global High-Speed Air-Flow Powder Sub-Filling Production Line Market:

The Global High-Speed Air-Flow Powder Sub-Filling Production Line Market finds extensive usage across various industries, including the pharmaceutical, food, and chemical sectors, among others. In the pharmaceutical industry, these production lines are essential for filling medicinal powders into capsules, sachets, and other containers with high precision. The accuracy and speed of these systems ensure that each dose contains the exact amount of active ingredients, which is crucial for patient safety and efficacy. Additionally, the use of air-flow technology minimizes the risk of contamination, maintaining the sterility of the products. In the food industry, high-speed air-flow powder sub-filling production lines are used to fill powdered food products such as spices, protein powders, and instant drink mixes. The ability to fill these products quickly and accurately helps manufacturers meet the high demand while maintaining product quality. The technology ensures that the powders are evenly distributed, preventing issues like clumping or uneven filling, which can affect the product's shelf life and consumer satisfaction. In the chemical industry, these production lines are used to fill various powdered chemicals into containers for distribution and use in different applications. The precision and efficiency of these systems are particularly important for handling hazardous or reactive chemicals, where any spillage or contamination can have serious consequences. The air-flow technology helps in maintaining a clean and safe working environment by reducing dust and airborne particles. Other industries that benefit from high-speed air-flow powder sub-filling production lines include cosmetics, where they are used to fill powdered makeup products, and the agricultural sector, where they are used for filling powdered fertilizers and pesticides. The versatility and efficiency of these production lines make them valuable assets in any industry that deals with powdered products.

Global High-Speed Air-Flow Powder Sub-Filling Production Line Market Outlook:

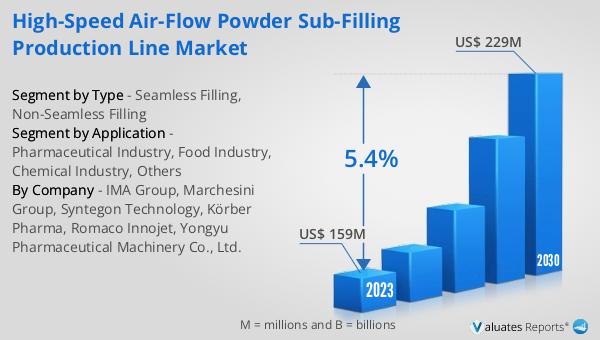

The global High-Speed Air-Flow Powder Sub-Filling Production Line market was valued at US$ 159 million in 2023 and is anticipated to reach US$ 229 million by 2030, witnessing a CAGR of 5.4% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for automation and efficiency in various industries. The adoption of high-speed air-flow powder sub-filling production lines is expected to rise as companies seek to enhance their production capabilities and meet stringent quality standards. The market's growth is also supported by advancements in technology, which are making these systems more efficient and reliable. As industries continue to evolve and the need for precision and speed in manufacturing processes becomes more critical, the demand for high-speed air-flow powder sub-filling production lines is likely to increase. This growth trend underscores the importance of investing in advanced production technologies to stay competitive in the global market.

| Report Metric | Details |

| Report Name | High-Speed Air-Flow Powder Sub-Filling Production Line Market |

| Accounted market size in 2023 | US$ 159 million |

| Forecasted market size in 2030 | US$ 229 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | IMA Group, Marchesini Group, Syntegon Technology, Körber Pharma, Romaco Innojet, Yongyu Pharmaceutical Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |