What is Plastic Processing Auxiliary Equipment - Global Market?

Plastic Processing Auxiliary Equipment refers to the various machines and tools used to support the primary plastic processing machinery. These auxiliary devices are essential for enhancing the efficiency, quality, and speed of plastic production processes. The global market for these auxiliary equipment is vast and diverse, encompassing a wide range of products such as dryers, loaders, temperature controllers, and granulators, among others. These tools are crucial in ensuring that the plastic manufacturing process is smooth and efficient, helping to maintain the desired quality of the final product. The market for plastic processing auxiliary equipment is driven by the increasing demand for plastic products across various industries, including automotive, packaging, and consumer goods. As industries continue to innovate and develop new plastic products, the need for advanced auxiliary equipment grows, leading to a dynamic and evolving market landscape. The global market for these auxiliary tools is characterized by technological advancements, with manufacturers constantly developing new and improved equipment to meet the changing needs of the industry. This market is expected to continue growing as the demand for high-quality plastic products increases worldwide.

Drying Equipment, Transportation Equipment, Other in the Plastic Processing Auxiliary Equipment - Global Market:

Drying equipment, transportation equipment, and other auxiliary tools play a significant role in the plastic processing auxiliary equipment market. Drying equipment is crucial in removing moisture from plastic resins before they are processed. Moisture in plastic resins can lead to defects in the final product, such as bubbles or weak spots, which can compromise the quality and durability of the plastic item. Therefore, drying equipment is essential in ensuring that the plastic resins are in optimal condition for processing. Various types of drying equipment are available in the market, including desiccant dryers, hot air dryers, and vacuum dryers, each offering different advantages depending on the specific requirements of the plastic processing operation. Transportation equipment, on the other hand, is used to move plastic materials from one stage of the production process to another. This includes conveyors, feeders, and loaders, which help in efficiently transporting plastic resins and finished products within the manufacturing facility. Efficient transportation equipment is vital in minimizing production downtime and ensuring a smooth workflow in the plastic processing plant. Other auxiliary equipment includes temperature controllers, which are used to maintain the desired temperature during the plastic processing operation. Temperature control is critical in ensuring that the plastic material is processed at the right temperature to achieve the desired properties in the final product. Granulators and shredders are also part of the auxiliary equipment, used to recycle plastic waste and reduce material costs. These machines break down plastic waste into smaller pieces, which can then be reprocessed into new products. The use of granulators and shredders is becoming increasingly important as industries focus on sustainability and reducing their environmental impact. Overall, the plastic processing auxiliary equipment market is diverse and encompasses a wide range of tools and machines that are essential in ensuring the efficiency and quality of plastic production processes. As the demand for plastic products continues to grow, the need for advanced and efficient auxiliary equipment will also increase, driving innovation and development in this market.

Food, Pharmaceutical, Automobile, Other in the Plastic Processing Auxiliary Equipment - Global Market:

Plastic processing auxiliary equipment finds extensive usage across various industries, including food, pharmaceutical, automobile, and others. In the food industry, these auxiliary tools are used to produce packaging materials that are essential for preserving the quality and safety of food products. The use of high-quality plastic packaging helps in extending the shelf life of food items and protecting them from contamination. Auxiliary equipment such as dryers and temperature controllers are crucial in ensuring that the plastic packaging materials meet the required standards for food safety and quality. In the pharmaceutical industry, plastic processing auxiliary equipment is used to manufacture packaging materials for medicines and medical devices. The precision and quality of these packaging materials are critical in ensuring the safety and efficacy of pharmaceutical products. Auxiliary equipment helps in maintaining the required standards for pharmaceutical packaging by ensuring that the plastic materials are processed under optimal conditions. In the automobile industry, plastic processing auxiliary equipment is used to produce various components and parts, such as dashboards, bumpers, and interior trims. The use of plastic in the automotive industry is driven by the need for lightweight and durable materials that can enhance fuel efficiency and reduce emissions. Auxiliary equipment plays a vital role in ensuring that the plastic components meet the required specifications for performance and safety. Other industries, such as consumer goods and electronics, also rely on plastic processing auxiliary equipment to produce a wide range of products. The versatility and efficiency of these auxiliary tools make them indispensable in the production of high-quality plastic products across various sectors. As industries continue to innovate and develop new plastic products, the demand for advanced auxiliary equipment will continue to grow, driving the expansion of the global market for plastic processing auxiliary equipment.

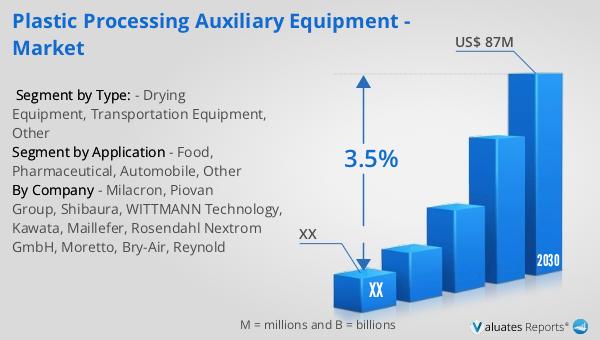

Plastic Processing Auxiliary Equipment - Global Market Outlook:

The global market for Plastic Processing Auxiliary Equipment was valued at approximately $69 million in 2023. It is projected to grow to a revised size of $87 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for plastic products across various industries, which in turn drives the need for efficient and advanced auxiliary equipment. The North American market for Plastic Processing Auxiliary Equipment also shows promising growth prospects. Although specific figures for the North American market in 2023 and 2030 are not provided, it is expected to follow a similar growth trajectory as the global market, driven by technological advancements and the increasing demand for high-quality plastic products. The growth in the North American market is supported by the presence of key players in the plastic processing industry and the continuous innovation in auxiliary equipment technology. As industries in North America continue to expand and develop new plastic products, the demand for advanced auxiliary equipment will also increase, contributing to the overall growth of the market. The forecasted growth in both the global and North American markets highlights the importance of plastic processing auxiliary equipment in enhancing the efficiency and quality of plastic production processes. As the demand for plastic products continues to rise, the market for these auxiliary tools is expected to expand, driven by technological advancements and the need for high-quality plastic products across various industries.

| Report Metric | Details |

| Report Name | Plastic Processing Auxiliary Equipment - Market |

| Forecasted market size in 2030 | US$ 87 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Milacron, Piovan Group, Shibaura, WITTMANN Technology, Kawata, Maillefer, Rosendahl Nextrom GmbH, Moretto, Bry-Air, Reynold |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |