What is Dental Orthodontic 3D Printer - Global Market?

Dental orthodontic 3D printers are revolutionizing the way dental professionals approach orthodontic treatments by providing a more efficient and precise method for creating dental appliances. These advanced printers use digital models to produce highly accurate orthodontic devices such as aligners, retainers, and braces. The global market for dental orthodontic 3D printers is expanding rapidly due to the increasing demand for customized dental solutions and the growing adoption of digital dentistry. This technology not only reduces the time required to produce dental appliances but also enhances the accuracy and fit, leading to improved patient outcomes. As more dental practices and laboratories recognize the benefits of 3D printing, the market is expected to continue its upward trajectory, driven by technological advancements and the need for cost-effective, high-quality dental care solutions. The integration of 3D printing in orthodontics is transforming the industry, offering a more streamlined and patient-friendly approach to dental care.

Vat Photopolymerization, Fused Deposition Modeling, Polyjet Technology, Others in the Dental Orthodontic 3D Printer - Global Market:

Vat photopolymerization, fused deposition modeling (FDM), PolyJet technology, and other methods are pivotal in the dental orthodontic 3D printer market, each offering unique advantages for creating dental appliances. Vat photopolymerization is a process where a liquid photopolymer resin is cured layer by layer using a light source, typically a laser or digital light projector. This method is renowned for its high precision and ability to produce intricate details, making it ideal for creating complex dental models and appliances. The accuracy of vat photopolymerization ensures that dental devices fit perfectly, enhancing patient comfort and treatment efficacy. Fused deposition modeling, on the other hand, involves the extrusion of thermoplastic materials through a heated nozzle, building objects layer by layer. While FDM is generally less precise than vat photopolymerization, it is cost-effective and suitable for producing durable dental models and prototypes. Its affordability makes it accessible for smaller dental practices and laboratories looking to adopt 3D printing technology. PolyJet technology is another popular method in the dental orthodontic 3D printer market. It works by jetting layers of liquid photopolymer onto a build tray, which are then cured with UV light. PolyJet is known for its ability to produce smooth surfaces and fine details, making it ideal for creating highly detailed dental models and appliances. This technology also allows for the use of multiple materials and colors in a single print, offering versatility in dental applications. Other methods, such as selective laser sintering (SLS) and stereolithography (SLA), also play a role in the dental orthodontic 3D printer market. SLS uses a laser to fuse powdered materials, creating strong and durable dental models, while SLA employs a laser to cure liquid resin, similar to vat photopolymerization. Each of these technologies offers distinct benefits, allowing dental professionals to choose the most suitable method based on their specific needs and requirements. As the dental orthodontic 3D printer market continues to evolve, these technologies are expected to advance further, offering even greater precision, speed, and versatility in dental applications.

Laboratories, Clinics in the Dental Orthodontic 3D Printer - Global Market:

Dental orthodontic 3D printers are increasingly being utilized in both laboratories and clinics, transforming the way dental professionals create and deliver orthodontic treatments. In dental laboratories, 3D printers are used to produce a wide range of orthodontic appliances, including aligners, retainers, and braces. The ability to create highly accurate and customized devices quickly and efficiently is a significant advantage for laboratories, allowing them to meet the growing demand for personalized dental solutions. By using digital models and 3D printing technology, laboratories can reduce production times and costs, while also improving the quality and fit of the appliances they produce. This not only enhances patient satisfaction but also streamlines the workflow for dental professionals. In dental clinics, 3D printers are used to create in-house orthodontic appliances, enabling dentists to offer same-day solutions for their patients. This is particularly beneficial for practices that want to provide immediate treatment options, such as temporary crowns or aligners. The use of 3D printing in clinics also allows for greater control over the production process, ensuring that appliances are tailored to the specific needs of each patient. Additionally, the ability to produce appliances on-site reduces the need for outsourcing, leading to cost savings and faster turnaround times. As more clinics adopt 3D printing technology, patients can expect more efficient and personalized dental care. The integration of 3D printing in both laboratories and clinics is revolutionizing the dental industry, offering a more efficient, accurate, and patient-friendly approach to orthodontic treatment.

Dental Orthodontic 3D Printer - Global Market Outlook:

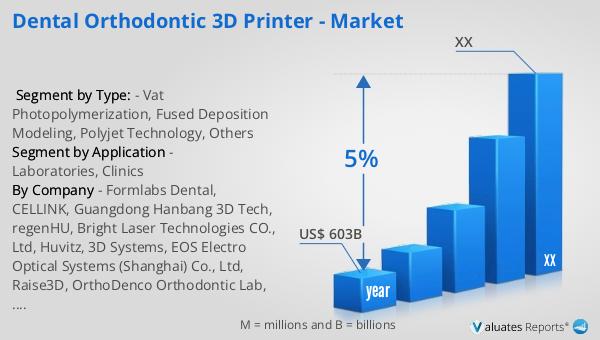

Our research indicates that the global market for medical devices, which includes dental orthodontic 3D printers, is valued at approximately $603 billion in 2023. This market is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing demand for advanced medical technologies, the rising prevalence of chronic diseases, and the growing aging population. As healthcare systems worldwide continue to evolve, there is a greater emphasis on improving patient outcomes and reducing healthcare costs. Dental orthodontic 3D printers play a crucial role in this landscape by offering cost-effective and efficient solutions for creating customized dental appliances. The ability to produce high-quality, precise dental devices quickly and affordably is a significant advantage for dental professionals and patients alike. As the market for medical devices continues to expand, dental orthodontic 3D printers are expected to play an increasingly important role in the delivery of advanced dental care. This growth presents opportunities for manufacturers and healthcare providers to innovate and improve the quality of care for patients around the world.

| Report Metric | Details |

| Report Name | Dental Orthodontic 3D Printer - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Formlabs Dental, CELLINK, Guangdong Hanbang 3D Tech, regenHU, Bright Laser Technologies CO., Ltd, Huvitz, 3D Systems, EOS Electro Optical Systems (Shanghai) Co., Ltd, Raise3D, OrthoDenco Orthodontic Lab, Carbon, Rapidshape GmbH, CREALITY 3D |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |