What is 3D-Printed Medicinal Tablet - Global Market?

3D-printed medicinal tablets represent a groundbreaking advancement in the pharmaceutical industry, offering a new frontier in personalized medicine. This innovative technology allows for the creation of tablets that are tailored to the specific needs of individual patients, enhancing the efficacy and safety of treatments. By utilizing 3D printing, manufacturers can produce tablets with precise dosages, customized release profiles, and even complex drug combinations that are difficult to achieve with traditional manufacturing methods. The global market for 3D-printed medicinal tablets is rapidly expanding as healthcare providers and pharmaceutical companies recognize the potential benefits of this technology. It promises to revolutionize the way medications are developed and delivered, making treatments more accessible and effective for patients worldwide. As the technology continues to evolve, it is expected to play a significant role in addressing the challenges of modern healthcare, such as improving patient adherence to medication regimens and reducing the risk of adverse drug reactions. The integration of 3D printing in pharmaceuticals is not just a technological advancement but a step towards more patient-centric healthcare solutions.

Fused Deposition Modelling, Inkjet Printing, Zip Dose, Vat Photopolymerization in the 3D-Printed Medicinal Tablet - Global Market:

Fused Deposition Modelling (FDM), Inkjet Printing, Zip Dose, and Vat Photopolymerization are pivotal technologies in the realm of 3D-printed medicinal tablets, each contributing uniquely to the global market. FDM is a popular 3D printing technique that involves the layer-by-layer deposition of thermoplastic materials to create solid objects. In the context of medicinal tablets, FDM allows for the precise control of drug release profiles by manipulating the geometry and composition of the tablet. This method is particularly advantageous for producing tablets with complex shapes and structures that can enhance drug delivery and absorption. Inkjet Printing, on the other hand, utilizes a liquid-based approach where droplets of drug-containing solutions are deposited onto a substrate to form a tablet. This technique is highly versatile and can accommodate a wide range of active pharmaceutical ingredients (APIs), making it suitable for producing multi-drug tablets with precise dosages. Inkjet printing also enables the creation of tablets with intricate designs and patterns, which can be used to control the release rate of the drug. Zip Dose technology is a proprietary method developed by Aprecia Pharmaceuticals, known for its ability to produce rapidly disintegrating tablets. This technology uses a combination of 3D printing and traditional pharmaceutical processes to create tablets that dissolve quickly in the mouth, providing a convenient and effective delivery method for patients who have difficulty swallowing conventional tablets. Zip Dose is particularly beneficial for pediatric and geriatric populations, where ease of administration is crucial. Vat Photopolymerization, also known as stereolithography, involves the use of a light source to cure liquid resin into solid structures. In the pharmaceutical industry, this technology is used to create highly detailed and accurate tablet designs that can incorporate multiple drugs and release mechanisms. Vat Photopolymerization offers the advantage of producing tablets with high precision and consistency, which is essential for ensuring the safety and efficacy of the medication. Each of these technologies plays a vital role in the development and production of 3D-printed medicinal tablets, contributing to the growth and diversification of the global market. As these technologies continue to advance, they hold the potential to transform the pharmaceutical industry by enabling the production of personalized and complex medications that meet the specific needs of individual patients.

Hospitals and Clinics, Research Laboratories, Pharmaceutical, Others in the 3D-Printed Medicinal Tablet - Global Market:

The usage of 3D-printed medicinal tablets is gaining traction across various sectors, including hospitals and clinics, research laboratories, pharmaceutical companies, and other healthcare settings. In hospitals and clinics, 3D-printed tablets offer a promising solution for personalized medicine, allowing healthcare providers to tailor treatments to the unique needs of each patient. This customization can lead to improved patient outcomes by ensuring that the right dosage and combination of drugs are administered. Additionally, the ability to produce tablets on-demand can reduce the need for large inventories of medications, minimizing waste and lowering costs for healthcare facilities. Research laboratories are also exploring the potential of 3D-printed tablets to accelerate drug development and testing. By using 3D printing technology, researchers can quickly produce prototypes of new drug formulations and test their efficacy and safety in preclinical studies. This rapid prototyping capability can significantly shorten the drug development timeline, bringing new treatments to market faster. Pharmaceutical companies are leveraging 3D printing to enhance their manufacturing processes and expand their product offerings. The technology allows for the production of complex drug formulations that are difficult to achieve with traditional methods, such as multi-drug tablets and controlled-release formulations. This capability not only improves the therapeutic efficacy of medications but also opens up new opportunities for innovation in drug design. Other healthcare settings, such as nursing homes and home care environments, can benefit from 3D-printed tablets by providing patients with more convenient and effective medication options. For patients with swallowing difficulties or those who require multiple medications, 3D-printed tablets can be customized to meet their specific needs, improving adherence to treatment regimens and enhancing overall quality of life. As the adoption of 3D-printed medicinal tablets continues to grow, it is expected to have a transformative impact on the healthcare industry, offering new possibilities for personalized and efficient patient care.

3D-Printed Medicinal Tablet - Global Market Outlook:

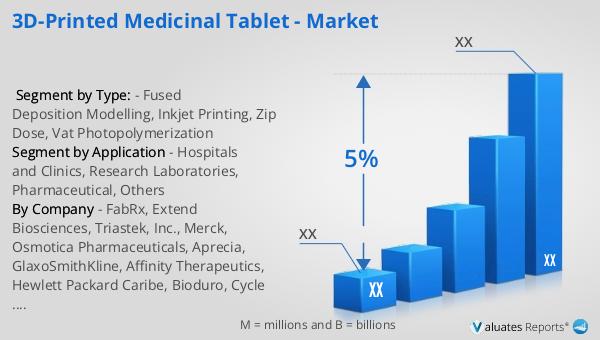

The outlook for the 3D-printed medicinal tablet market is promising, especially when viewed in the context of the broader pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for innovative healthcare solutions, including 3D-printed medicinal tablets. In comparison, the chemical drug market, which forms a significant part of the pharmaceutical industry, was projected to grow from 1,005 billion USD in 2018 to 1,094 billion USD by 2022. This steady growth highlights the ongoing need for traditional pharmaceuticals, while also underscoring the potential for new technologies like 3D printing to complement and enhance existing drug delivery methods. As the pharmaceutical industry continues to evolve, the integration of 3D printing technology is expected to play a crucial role in meeting the diverse needs of patients and healthcare providers. By offering personalized and efficient medication solutions, 3D-printed medicinal tablets have the potential to revolutionize the way drugs are manufactured and administered, contributing to the overall growth and innovation within the pharmaceutical market.

| Report Metric | Details |

| Report Name | 3D-Printed Medicinal Tablet - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | FabRx, Extend Biosciences, Triastek, Inc., Merck, Osmotica Pharmaceuticals, Aprecia, GlaxoSmithKline, Affinity Therapeutics, Hewlett Packard Caribe, Bioduro, Cycle Pharmaceuticals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |