What is Pharmaceutical IBC Container - Global Market?

Pharmaceutical Intermediate Bulk Containers (IBC) are specialized containers used globally for the storage and transportation of bulk pharmaceutical products. These containers are designed to handle large volumes of liquid or solid pharmaceutical ingredients, ensuring their safety and integrity during transit. The global market for pharmaceutical IBC containers is driven by the increasing demand for efficient and safe transportation solutions in the pharmaceutical industry. These containers are typically made from high-grade materials such as stainless steel or high-density polyethylene, which provide excellent resistance to contamination and corrosion. They are equipped with features like secure lids, valves, and liners to prevent leakage and contamination. The market is also influenced by stringent regulations and standards that mandate the use of high-quality containers for pharmaceutical products. As the pharmaceutical industry continues to grow, the demand for IBC containers is expected to rise, driven by the need for cost-effective and reliable packaging solutions. The versatility of these containers makes them suitable for a wide range of applications, from transporting raw materials to delivering finished products to healthcare facilities. Overall, the global market for pharmaceutical IBC containers is poised for steady growth, supported by advancements in container design and manufacturing technologies.

Powders, Bulk Solid in the Pharmaceutical IBC Container - Global Market:

Pharmaceutical IBC containers play a crucial role in the handling and transportation of powders and bulk solids within the pharmaceutical industry. These containers are specifically designed to accommodate the unique challenges associated with storing and moving large quantities of powdered substances. The global market for pharmaceutical IBC containers catering to powders and bulk solids is expanding due to the increasing demand for efficient and safe handling solutions. These containers are engineered to ensure the integrity and quality of the powders they carry, preventing contamination and degradation. They are often constructed from robust materials like stainless steel or high-density polyethylene, which offer excellent protection against environmental factors. The design of these containers includes features such as secure lids, valves, and liners that facilitate easy loading and unloading while minimizing the risk of spillage or contamination. The pharmaceutical industry relies heavily on these containers for the transportation of active pharmaceutical ingredients (APIs), excipients, and other bulk materials used in drug manufacturing. The ability to transport large volumes of powders efficiently is critical for maintaining production schedules and meeting market demands. Moreover, the use of IBC containers helps pharmaceutical companies comply with stringent regulatory requirements related to the safe handling and transportation of bulk materials. The market for pharmaceutical IBC containers is also driven by the need for cost-effective solutions that reduce packaging waste and improve operational efficiency. These containers can be reused multiple times, making them an environmentally friendly option compared to single-use packaging. Additionally, the modular design of IBC containers allows for easy integration into existing logistics systems, further enhancing their appeal to pharmaceutical companies. As the pharmaceutical industry continues to evolve, the demand for innovative and reliable packaging solutions like IBC containers is expected to grow. The global market for these containers is characterized by ongoing advancements in design and manufacturing technologies, which aim to improve their performance and functionality. Manufacturers are investing in research and development to create containers that offer enhanced protection against contamination, improved durability, and greater ease of use. The increasing focus on sustainability is also driving innovation in the market, with companies exploring new materials and designs that minimize environmental impact. Overall, the global market for pharmaceutical IBC containers catering to powders and bulk solids is poised for significant growth, supported by the rising demand for efficient and sustainable packaging solutions in the pharmaceutical industry.

Pharmaceutical, Food, Chemical Industries, Others in the Pharmaceutical IBC Container - Global Market:

Pharmaceutical IBC containers are widely used across various industries, including pharmaceuticals, food, and chemicals, due to their versatility and efficiency. In the pharmaceutical industry, these containers are essential for the safe and efficient transportation of bulk materials such as active pharmaceutical ingredients (APIs), excipients, and finished products. They ensure the integrity and quality of the materials they carry, preventing contamination and degradation. The use of IBC containers in the pharmaceutical industry is driven by the need for cost-effective and reliable packaging solutions that comply with stringent regulatory requirements. These containers are designed to withstand the rigors of transportation and storage, providing excellent protection against environmental factors. In the food industry, IBC containers are used to transport bulk ingredients such as grains, powders, and liquids. They offer a hygienic and efficient solution for handling large volumes of food products, ensuring their safety and quality. The use of IBC containers in the food industry is driven by the need for efficient logistics solutions that minimize packaging waste and reduce costs. These containers are designed to be easily cleaned and sanitized, making them suitable for transporting food products. In the chemical industry, IBC containers are used to transport bulk chemicals and hazardous materials. They provide a safe and secure solution for handling potentially dangerous substances, ensuring compliance with safety regulations. The use of IBC containers in the chemical industry is driven by the need for reliable and cost-effective packaging solutions that can withstand the harsh conditions associated with chemical transportation. These containers are designed to offer excellent resistance to corrosion and contamination, making them ideal for transporting a wide range of chemical products. In addition to these industries, IBC containers are also used in other sectors such as agriculture, cosmetics, and manufacturing. Their versatility and efficiency make them a popular choice for businesses looking to optimize their logistics operations and reduce costs. Overall, the global market for pharmaceutical IBC containers is characterized by a growing demand for innovative and reliable packaging solutions across various industries. As businesses continue to seek cost-effective and sustainable logistics solutions, the demand for IBC containers is expected to rise, driven by their versatility and efficiency.

Pharmaceutical IBC Container - Global Market Outlook:

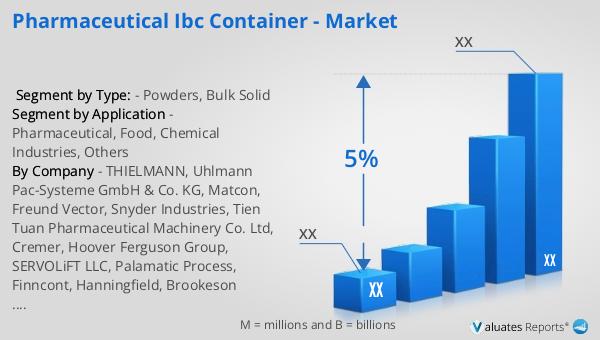

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, reflecting a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising healthcare expenditures, and advancements in medical technology. In comparison, the chemical drug market has also shown significant growth, expanding from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This increase highlights the ongoing demand for chemical-based pharmaceuticals, which continue to play a crucial role in the treatment and management of various health conditions. The growth in both the pharmaceutical and chemical drug markets underscores the importance of efficient and reliable packaging solutions, such as pharmaceutical IBC containers, to support the safe and effective transportation of bulk materials. As the demand for pharmaceutical products continues to rise, the need for innovative and sustainable packaging solutions will become increasingly important, driving further growth in the global market for pharmaceutical IBC containers.

| Report Metric | Details |

| Report Name | Pharmaceutical IBC Container - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | THIELMANN, Uhlmann Pac-Systeme GmbH & Co. KG, Matcon, Freund Vector, Snyder Industries, Tien Tuan Pharmaceutical Machinery Co. Ltd, Cremer, Hoover Ferguson Group, SERVOLiFT LLC, Palamatic Process, Finncont, Hanningfield, Brookeson Material Handling Ltd., Titan IBC, SCHÄFER Container Systems, GEA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |