What is Centralized Grease Lubrication System - Global Market?

Centralized grease lubrication systems are an essential component in various industries, designed to deliver precise amounts of lubricant to multiple points in a machine or vehicle from a central location. This system ensures that all moving parts receive adequate lubrication, reducing wear and tear and extending the lifespan of machinery. The global market for centralized grease lubrication systems is witnessing significant growth due to the increasing demand for efficient and reliable lubrication solutions in industries such as automotive, manufacturing, and construction. These systems are particularly beneficial in environments where manual lubrication is challenging or impractical, providing a more efficient and less labor-intensive solution. The systems are designed to operate automatically, ensuring consistent lubrication and minimizing the risk of human error. As industries continue to prioritize operational efficiency and equipment longevity, the adoption of centralized grease lubrication systems is expected to rise, driving market growth. The systems are also becoming more advanced, with features such as remote monitoring and control, which further enhance their appeal to businesses looking to optimize their maintenance processes.

Grease-based Lubrication System, Oil-based Lubrication System, Others in the Centralized Grease Lubrication System - Global Market:

Grease-based lubrication systems are a subset of centralized lubrication systems that use grease as the primary lubricant. These systems are particularly effective in applications where high-pressure lubrication is required, such as in heavy machinery and equipment used in construction and mining. Grease-based systems are designed to deliver the lubricant in a controlled manner, ensuring that all critical components receive the necessary lubrication to function optimally. The use of grease as a lubricant offers several advantages, including its ability to stay in place and provide a protective barrier against contaminants. This makes grease-based systems ideal for harsh environments where dust, dirt, and moisture are prevalent. On the other hand, oil-based lubrication systems use oil as the primary lubricant and are typically used in applications where lower viscosity lubrication is needed. These systems are common in industries such as automotive and manufacturing, where precise lubrication is crucial for the smooth operation of machinery. Oil-based systems offer the advantage of being able to flow easily into tight spaces, providing comprehensive coverage to all moving parts. However, they may require more frequent maintenance compared to grease-based systems due to the potential for oil leakage and evaporation. Other types of centralized lubrication systems may include those that use synthetic lubricants or specialized formulations designed for specific applications. These systems are often tailored to meet the unique needs of particular industries or machinery, offering customized solutions that enhance performance and efficiency. As the global market for centralized grease lubrication systems continues to evolve, businesses are increasingly seeking out systems that offer the best combination of performance, reliability, and cost-effectiveness. This has led to the development of innovative lubrication solutions that cater to a wide range of industrial needs, ensuring that machinery and equipment operate at peak efficiency.

Passenger Vehicles, Light Commercial Vehicles, Heavy Commercial Vehicles, Others in the Centralized Grease Lubrication System - Global Market:

The usage of centralized grease lubrication systems in passenger vehicles is primarily focused on enhancing the performance and longevity of various components such as bearings, joints, and suspension systems. These systems ensure that all critical parts receive the necessary lubrication, reducing friction and wear, and ultimately leading to a smoother and more reliable driving experience. In light commercial vehicles, centralized grease lubrication systems play a crucial role in maintaining the efficiency and durability of the vehicle's mechanical components. These systems are particularly beneficial in fleet operations where vehicles are subjected to rigorous use and require consistent maintenance to avoid downtime. By automating the lubrication process, businesses can ensure that their vehicles remain in optimal condition, reducing the need for frequent manual maintenance and minimizing the risk of unexpected breakdowns. In heavy commercial vehicles, such as trucks and buses, centralized grease lubrication systems are essential for maintaining the performance and reliability of critical components such as axles, drive shafts, and steering systems. These vehicles often operate in demanding conditions and require robust lubrication solutions to withstand the stresses of heavy loads and long-distance travel. Centralized systems provide a reliable and efficient means of delivering the necessary lubrication, ensuring that all components function smoothly and reducing the risk of costly repairs. Other applications of centralized grease lubrication systems can be found in industries such as agriculture, construction, and manufacturing, where machinery and equipment are subjected to harsh operating conditions. In these environments, centralized systems offer a practical solution for maintaining the performance and longevity of equipment, reducing the need for manual lubrication and minimizing the risk of equipment failure. As industries continue to prioritize efficiency and reliability, the adoption of centralized grease lubrication systems is expected to increase, driving market growth and innovation in this sector.

Centralized Grease Lubrication System - Global Market Outlook:

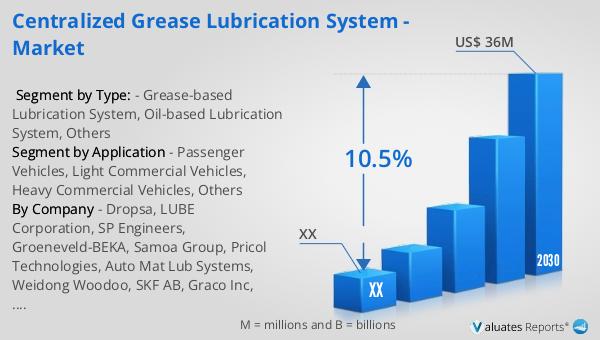

The global market for centralized grease lubrication systems was valued at approximately $13 million in 2023, with projections indicating a significant increase to $36 million by 2030. This growth represents a compound annual growth rate (CAGR) of 10.5% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to experience substantial growth, although specific figures for this region were not provided. The increasing demand for efficient and reliable lubrication solutions across various industries is a key driver of this market expansion. As businesses continue to seek ways to enhance operational efficiency and reduce maintenance costs, the adoption of centralized grease lubrication systems is likely to rise. These systems offer numerous benefits, including automated lubrication, reduced labor costs, and improved equipment performance, making them an attractive option for companies looking to optimize their maintenance processes. Additionally, advancements in technology, such as remote monitoring and control capabilities, are further enhancing the appeal of these systems, providing businesses with greater flexibility and control over their lubrication processes. As the market continues to grow, companies are expected to invest in research and development to create more advanced and efficient lubrication solutions, catering to the evolving needs of various industries.

| Report Metric | Details |

| Report Name | Centralized Grease Lubrication System - Market |

| Forecasted market size in 2030 | US$ 36 million |

| CAGR | 10.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dropsa, LUBE Corporation, SP Engineers, Groeneveld-BEKA, Samoa Group, Pricol Technologies, Auto Mat Lub Systems, Weidong Woodoo, SKF AB, Graco Inc, Cenlub Systems, Vogel AG, Beka-Lube |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |