What is Container Cleaning Equipment - Global Market?

Container cleaning equipment plays a crucial role in various industries by ensuring that containers used for storage and transportation are free from contaminants. This equipment is designed to clean containers of different sizes and materials, such as plastic, metal, and glass, which are commonly used in sectors like food and beverages, pharmaceuticals, and chemicals. The global market for container cleaning equipment is driven by the increasing demand for hygiene and safety standards across these industries. As businesses strive to maintain high-quality standards and comply with stringent regulations, the need for efficient and reliable cleaning solutions has become paramount. The equipment ranges from simple manual cleaning tools to sophisticated automated systems that can handle large volumes of containers with minimal human intervention. This market is characterized by continuous innovation, with manufacturers focusing on developing eco-friendly and energy-efficient solutions to meet the evolving needs of their customers. As a result, the container cleaning equipment market is poised for significant growth, driven by technological advancements and the increasing emphasis on sustainability and operational efficiency.

Fully Automatic, Semi-automatic, Other in the Container Cleaning Equipment - Global Market:

Container cleaning equipment can be broadly categorized into fully automatic, semi-automatic, and other types, each offering distinct advantages and catering to different operational needs. Fully automatic container cleaning equipment is designed for high-volume operations where speed and efficiency are critical. These systems are equipped with advanced features such as programmable logic controllers (PLCs), automated conveyor systems, and high-pressure cleaning nozzles that ensure thorough cleaning with minimal human intervention. They are ideal for industries that require consistent and repeatable cleaning processes, such as the food and beverage sector, where hygiene is of utmost importance. The automation not only reduces labor costs but also minimizes the risk of human error, ensuring that containers are cleaned to the highest standards. Semi-automatic container cleaning equipment, on the other hand, offers a balance between manual and automated processes. These systems typically require some level of human involvement, such as loading and unloading containers, but the cleaning process itself is automated. This type of equipment is suitable for operations where flexibility is needed, allowing operators to adjust cleaning parameters based on the specific requirements of different container types and sizes. Semi-automatic systems are often more cost-effective than fully automatic ones, making them an attractive option for small to medium-sized enterprises that need reliable cleaning solutions without a significant upfront investment. Other types of container cleaning equipment include manual cleaning tools and specialized systems designed for niche applications. Manual cleaning tools, such as brushes and handheld sprayers, are typically used for small-scale operations or in situations where automated systems are not feasible. These tools offer a high degree of control and are often used for cleaning containers with intricate designs or hard-to-reach areas. Specialized systems, on the other hand, are designed to meet the unique needs of specific industries or applications. For example, some systems are equipped with ultrasonic cleaning technology, which uses high-frequency sound waves to remove contaminants from containers. This technology is particularly effective for cleaning delicate or sensitive materials, such as those used in the pharmaceutical industry. Overall, the choice between fully automatic, semi-automatic, and other types of container cleaning equipment depends on various factors, including the scale of operations, budget constraints, and specific cleaning requirements. As the global market for container cleaning equipment continues to evolve, manufacturers are focusing on developing versatile and customizable solutions that can cater to the diverse needs of their customers.

Foods and Beverages, Pharmaceutical, Chemical, Other in the Container Cleaning Equipment - Global Market:

Container cleaning equipment is widely used across various industries, including food and beverages, pharmaceuticals, chemicals, and others, each with its unique requirements and challenges. In the food and beverage industry, maintaining hygiene and safety standards is paramount to prevent contamination and ensure product quality. Container cleaning equipment in this sector is designed to handle a wide range of containers, from bottles and cans to large storage tanks. These systems use high-pressure water jets, steam, and specialized cleaning agents to remove residues and sanitize containers, ensuring they are free from harmful bacteria and allergens. The equipment is often integrated into production lines to streamline operations and minimize downtime, allowing manufacturers to maintain high throughput while adhering to strict regulatory standards. In the pharmaceutical industry, container cleaning equipment plays a critical role in ensuring the purity and safety of products. Containers used for storing and transporting pharmaceutical ingredients and finished products must be thoroughly cleaned to prevent cross-contamination and maintain product integrity. The equipment used in this sector is often equipped with advanced features such as HEPA filters, clean-in-place (CIP) systems, and validation protocols to meet the stringent requirements of regulatory bodies like the FDA and EMA. These systems are designed to handle a variety of container types, including vials, ampoules, and drums, and are often customized to meet the specific needs of different pharmaceutical applications. The chemical industry also relies heavily on container cleaning equipment to ensure the safe handling and storage of hazardous materials. Containers used in this sector must be cleaned to remove residues that could react with new contents or pose a risk to workers and the environment. The equipment used in chemical applications is typically robust and designed to withstand harsh cleaning agents and high temperatures. It often includes features such as explosion-proof components and corrosion-resistant materials to ensure safe and efficient operation. Other industries, such as cosmetics, automotive, and agriculture, also utilize container cleaning equipment to maintain cleanliness and safety standards. In the cosmetics industry, for example, containers used for storing and packaging products must be free from contaminants to ensure product quality and consumer safety. The equipment used in this sector is often designed to handle delicate containers and is equipped with features such as gentle cleaning cycles and adjustable pressure settings. In the automotive industry, container cleaning equipment is used to clean parts and components before assembly, ensuring they are free from dirt and debris that could affect performance. Overall, container cleaning equipment is an essential tool for maintaining hygiene and safety standards across a wide range of industries. As businesses continue to prioritize quality and compliance, the demand for efficient and reliable cleaning solutions is expected to grow, driving innovation and development in the global container cleaning equipment market.

Container Cleaning Equipment - Global Market Outlook:

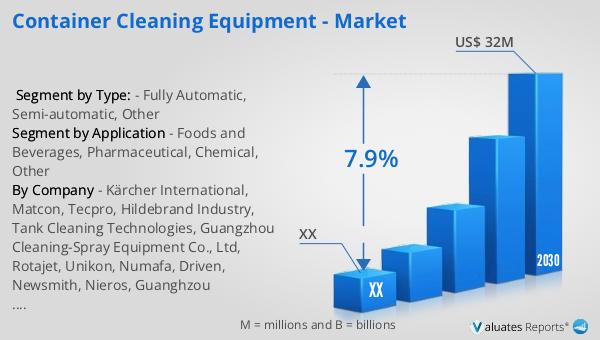

The global market for container cleaning equipment was valued at approximately $16 million in 2023, and it is projected to grow significantly, reaching an estimated $32 million by 2030. This growth represents a compound annual growth rate (CAGR) of 7.9% during the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for efficient and reliable cleaning solutions across various industries, driven by the need to maintain high hygiene and safety standards. The North American market for container cleaning equipment also shows promising growth prospects, although specific valuation figures for 2023 and projections for 2030 are not provided. However, it is expected to follow a similar growth trajectory as the global market, driven by technological advancements and the increasing emphasis on sustainability and operational efficiency. The growth in this market can be attributed to several factors, including the rising awareness of the importance of cleanliness and hygiene, stringent regulatory requirements, and the need for cost-effective and efficient cleaning solutions. As industries continue to prioritize quality and compliance, the demand for container cleaning equipment is expected to rise, driving innovation and development in this sector.

| Report Metric | Details |

| Report Name | Container Cleaning Equipment - Market |

| Forecasted market size in 2030 | US$ 32 million |

| CAGR | 7.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kärcher International, Matcon, Tecpro, Hildebrand Industry, Tank Cleaning Technologies, Guangzhou Cleaning-Spray Equipment Co., Ltd, Rotajet, Unikon, Numafa, Driven, Newsmith, Nieros, Guanghzou Cleaning-Spray Equipment, Douglas Machines, Bolondi, H&M Disinfection Systems Ltd, Central States Industrial, Adroit Machinery, Marchant Schmidt, Industrial Washing Machines Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |