What is Powder Containment Enclosure - Global Market?

Powder containment enclosures are specialized systems designed to safely handle and contain powders, dust, and other particulate materials in various industrial and laboratory settings. These enclosures are essential for maintaining a clean and safe working environment by preventing the escape of potentially hazardous particles into the surrounding area. They are commonly used in industries such as pharmaceuticals, chemicals, and food processing, where the handling of fine powders is a routine part of operations. The global market for powder containment enclosures is driven by the increasing demand for safety and hygiene in these industries, as well as the growing awareness of the health risks associated with exposure to airborne particles. These enclosures are designed to provide a controlled environment that minimizes the risk of contamination and exposure, ensuring the safety of workers and the integrity of the products being handled. As industries continue to prioritize safety and regulatory compliance, the demand for effective powder containment solutions is expected to grow, driving innovation and development in this market.

Lithium Nickel Manganese Containment Enclosure, Particle Reduction Enclosure, Other in the Powder Containment Enclosure - Global Market:

Lithium Nickel Manganese Cobalt Oxide (NMC) containment enclosures are a specific type of powder containment system designed to handle the unique challenges associated with the processing and handling of NMC powders. These materials are commonly used in the production of lithium-ion batteries, which are essential components in a wide range of electronic devices and electric vehicles. The handling of NMC powders requires specialized containment solutions due to their reactive nature and the potential health risks associated with exposure. NMC containment enclosures are designed to provide a controlled environment that minimizes the risk of contamination and exposure, ensuring the safety of workers and the integrity of the materials being handled. These enclosures are typically equipped with advanced filtration systems and airflow controls to effectively capture and contain airborne particles, preventing them from escaping into the surrounding environment. Particle reduction enclosures, on the other hand, are designed to minimize the presence of airborne particles in a given area. These enclosures are commonly used in industries such as pharmaceuticals and electronics, where even the smallest particles can have a significant impact on product quality and performance. Particle reduction enclosures are equipped with high-efficiency filtration systems that capture and remove particles from the air, creating a clean and controlled environment for sensitive processes. Other types of powder containment enclosures are designed to meet the specific needs of different industries and applications. These enclosures may be customized to accommodate unique materials, processes, or regulatory requirements, ensuring that they provide the necessary level of protection and containment for each specific application. The global market for powder containment enclosures is characterized by a diverse range of products and solutions, each designed to address the unique challenges and requirements of different industries and applications. As industries continue to evolve and new materials and processes are developed, the demand for innovative and effective powder containment solutions is expected to grow, driving further advancements in this market.

Pharmaceutical, Laboratory, Other in the Powder Containment Enclosure - Global Market:

Powder containment enclosures play a crucial role in the pharmaceutical industry, where the handling of fine powders is a routine part of operations. These enclosures are designed to provide a controlled environment that minimizes the risk of contamination and exposure, ensuring the safety of workers and the integrity of the products being handled. In pharmaceutical manufacturing, powder containment enclosures are used to handle active pharmaceutical ingredients (APIs) and other fine powders that are used in the production of medications. These enclosures are equipped with advanced filtration systems and airflow controls to effectively capture and contain airborne particles, preventing them from escaping into the surrounding environment. In laboratory settings, powder containment enclosures are used to handle a wide range of materials, from chemical reagents to biological samples. These enclosures provide a safe and controlled environment for researchers to conduct experiments and handle potentially hazardous materials. They are equipped with high-efficiency filtration systems that capture and remove particles from the air, creating a clean and controlled environment for sensitive processes. Other industries that use powder containment enclosures include food processing, electronics, and chemical manufacturing. In these industries, the handling of fine powders is a routine part of operations, and the need for effective containment solutions is critical to ensuring the safety of workers and the quality of the products being produced. Powder containment enclosures are designed to meet the specific needs of each industry, providing the necessary level of protection and containment for each specific application. As industries continue to prioritize safety and regulatory compliance, the demand for effective powder containment solutions is expected to grow, driving innovation and development in this market.

Powder Containment Enclosure - Global Market Outlook:

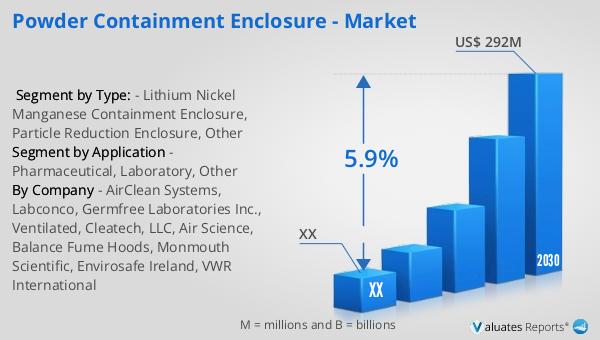

The global market for powder containment enclosures was valued at approximately $198 million in 2023, with projections indicating a growth to around $292 million by 2030. This growth represents a compound annual growth rate (CAGR) of 5.9% during the forecast period from 2024 to 2030. The North American market, a significant segment of the global landscape, was also valued at a substantial figure in 2023, with expectations of continued growth through 2030. This growth is driven by increasing demand for safety and hygiene in industries such as pharmaceuticals, chemicals, and food processing, where the handling of fine powders is a routine part of operations. The market's expansion is further supported by the growing awareness of the health risks associated with exposure to airborne particles, prompting industries to invest in effective containment solutions. As industries continue to prioritize safety and regulatory compliance, the demand for innovative and effective powder containment solutions is expected to grow, driving further advancements in this market. The market's growth is also supported by the development of new materials and processes, which require specialized containment solutions to ensure the safety of workers and the integrity of the products being handled.

| Report Metric | Details |

| Report Name | Powder Containment Enclosure - Market |

| Forecasted market size in 2030 | US$ 292 million |

| CAGR | 5.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AirClean Systems, Labconco, Germfree Laboratories Inc., Ventilated, Cleatech, LLC, Air Science, Balance Fume Hoods, Monmouth Scientific, Envirosafe Ireland, VWR International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |