What is Aluminum and Composites for Aerospace - Global Market?

Aluminum and composites are crucial materials in the aerospace industry, known for their lightweight and high-strength properties. Aluminum, a silvery-white metal, is prized for its low density and ability to resist corrosion, making it ideal for aircraft structures. It is used extensively in the aerospace sector for constructing fuselages, wings, and other critical components. Composites, on the other hand, are materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, they produce a material with characteristics different from the individual components. In aerospace, composites often refer to carbon fiber-reinforced polymers, which are incredibly strong yet lightweight. The global market for aluminum and composites in aerospace is driven by the need for fuel-efficient aircraft, as lighter materials contribute to lower fuel consumption. This market is characterized by continuous innovation and development, as manufacturers strive to create materials that offer better performance and sustainability. The demand for these materials is expected to grow as the aerospace industry expands, driven by increasing air travel and the need for modern, efficient aircraft. The market is also influenced by regulatory standards that require aircraft to be more environmentally friendly, pushing manufacturers to adopt advanced materials that reduce emissions and improve fuel efficiency.

Aluminum, Composites in the Aluminum and Composites for Aerospace - Global Market:

Aluminum has been a staple in the aerospace industry for decades due to its excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is used in various forms, such as sheets, plates, and extrusions, to build aircraft structures. The aerospace sector relies heavily on aluminum alloys, which are engineered to enhance specific properties like strength, ductility, and resistance to fatigue. These alloys are used in constructing aircraft fuselages, wings, and landing gear components, where durability and performance are critical. Composites based on aluminum, such as aluminum matrix composites, combine aluminum with other materials like ceramics or fibers to improve properties like stiffness, thermal stability, and wear resistance. These composites are used in applications where traditional aluminum might not meet the required performance standards. In the aerospace industry, composites are increasingly used to replace heavier metal parts, contributing to overall weight reduction and improved fuel efficiency. The global market for aluminum and composites in aerospace is driven by the need for lighter, more efficient aircraft. As air travel continues to grow, the demand for new aircraft with advanced materials is increasing. Manufacturers are investing in research and development to create innovative materials that meet the stringent requirements of the aerospace industry. This includes developing composites that offer superior strength, durability, and resistance to extreme temperatures and pressures. The market is also influenced by environmental regulations that require aircraft to reduce emissions and improve fuel efficiency. As a result, there is a growing trend towards using sustainable materials and manufacturing processes in the aerospace industry. The global market for aluminum and composites in aerospace is expected to continue growing as the industry evolves and new technologies emerge. This growth is supported by the increasing demand for commercial and military aircraft, as well as the development of new aerospace applications such as unmanned aerial vehicles and space exploration. The market is characterized by intense competition among manufacturers, who are constantly seeking to improve their products and gain a competitive edge. This has led to significant advancements in material science and engineering, resulting in the development of new alloys and composites that offer enhanced performance and sustainability. Overall, the global market for aluminum and composites in aerospace is a dynamic and rapidly evolving sector, driven by the need for innovative materials that meet the demands of modern aviation.

Commercial Aircraft, Military Aircraft, Helicopter in the Aluminum and Composites for Aerospace - Global Market:

In the aerospace industry, aluminum and composites play a vital role in the construction and performance of various types of aircraft, including commercial aircraft, military aircraft, and helicopters. In commercial aircraft, aluminum is extensively used in the construction of fuselages, wings, and other structural components. Its lightweight nature helps reduce the overall weight of the aircraft, leading to improved fuel efficiency and lower operating costs. Composites, particularly carbon fiber-reinforced polymers, are also used in commercial aircraft to further enhance performance. These materials offer superior strength and stiffness, allowing for the design of more aerodynamic and fuel-efficient aircraft. The use of composites in commercial aircraft is driven by the need to meet stringent environmental regulations and reduce carbon emissions. In military aircraft, aluminum and composites are used to achieve a balance between performance, durability, and stealth capabilities. Aluminum alloys are used in the construction of airframes and other critical components, providing the necessary strength and resistance to harsh environments. Composites are used to reduce the radar signature of military aircraft, enhancing their stealth capabilities. These materials also contribute to weight reduction, allowing for increased payload capacity and improved maneuverability. In helicopters, aluminum and composites are used to construct rotor blades, fuselages, and other structural components. The lightweight nature of these materials is crucial for helicopters, as it directly impacts their lift and performance. Composites are particularly important in helicopter design, as they offer the necessary strength and flexibility to withstand the stresses of rotary flight. The use of aluminum and composites in helicopters also contributes to improved fuel efficiency and reduced maintenance costs. Overall, the use of aluminum and composites in the aerospace industry is driven by the need for lightweight, durable, and efficient materials that meet the demands of modern aviation. These materials are essential for the development of advanced aircraft that offer improved performance, fuel efficiency, and environmental sustainability. As the aerospace industry continues to evolve, the demand for aluminum and composites is expected to grow, driven by the increasing need for innovative materials that meet the challenges of modern aviation.

Aluminum and Composites for Aerospace - Global Market Outlook:

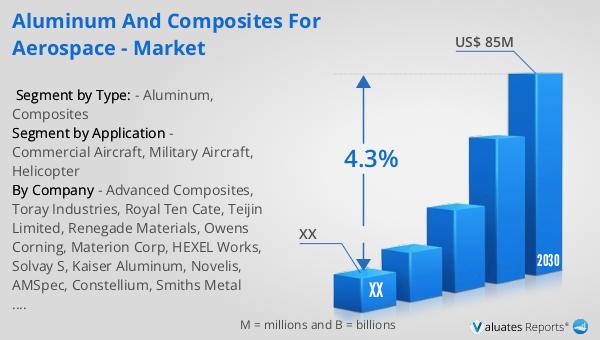

The global market for aluminum and composites in the aerospace sector was valued at approximately $64 million in 2023. This market is projected to grow steadily, reaching an estimated value of $85 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. The increasing demand for lightweight and fuel-efficient aircraft is a significant driver of this market growth. As airlines and aircraft manufacturers strive to reduce operating costs and meet environmental regulations, the adoption of advanced materials like aluminum and composites is becoming more prevalent. These materials offer the necessary strength and durability while contributing to overall weight reduction, leading to improved fuel efficiency and reduced emissions. The market is also influenced by advancements in material science and engineering, which are leading to the development of new alloys and composites with enhanced properties. These innovations are expected to further drive the demand for aluminum and composites in the aerospace industry. Additionally, the growing demand for military aircraft and the development of new aerospace applications, such as unmanned aerial vehicles and space exploration, are expected to contribute to the market's growth. Overall, the global market for aluminum and composites in aerospace is poised for steady growth, driven by the need for innovative materials that meet the demands of modern aviation.

| Report Metric | Details |

| Report Name | Aluminum and Composites for Aerospace - Market |

| Forecasted market size in 2030 | US$ 85 million |

| CAGR | 4.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Advanced Composites, Toray Industries, Royal Ten Cate, Teijin Limited, Renegade Materials, Owens Corning, Materion Corp, HEXEL Works, Solvay S, Kaiser Aluminum, Novelis, AMSpec, Constellium, Smiths Metal Centers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |