What is Global Water-Based Cutting Fluids Market?

The Global Water-Based Cutting Fluids Market is a significant segment within the industrial fluids sector, focusing on fluids used in machining and metalworking processes. These fluids are primarily composed of water, which acts as a base, and are designed to cool and lubricate cutting tools and workpieces during operations. The primary function of these fluids is to reduce heat and friction between the cutting tool and the material being worked on, thereby extending the life of the tool and improving the quality of the finished product. Water-based cutting fluids are preferred in many industries due to their environmental benefits, cost-effectiveness, and efficiency in heat dissipation. They are less harmful to the environment compared to oil-based fluids and are easier to dispose of, making them a sustainable choice for manufacturers. The market for these fluids is driven by the growing demand in various sectors such as automotive, aerospace, and machinery manufacturing, where precision and efficiency are paramount. As industries continue to seek more sustainable and efficient manufacturing processes, the demand for water-based cutting fluids is expected to grow, reflecting a shift towards more environmentally friendly industrial practices.

Emulsion, Chemical Synthesis Liquid, Semi-Synthetic Liquid in the Global Water-Based Cutting Fluids Market:

In the realm of Global Water-Based Cutting Fluids Market, three primary types of fluids are prevalent: Emulsion, Chemical Synthesis Liquid, and Semi-Synthetic Liquid. Emulsion-based cutting fluids are a mixture of oil and water, where oil droplets are dispersed in water with the help of emulsifiers. These fluids are known for their excellent cooling properties and are widely used in heavy-duty machining operations. The presence of oil in the emulsion provides lubrication, reducing friction and wear on cutting tools. Emulsions are particularly effective in operations where high heat is generated, such as in the automotive and aerospace industries. On the other hand, Chemical Synthesis Liquids are entirely synthetic and do not contain any mineral oil. These fluids are formulated using chemical compounds that provide both cooling and lubricating properties. They are known for their stability and long service life, making them ideal for precision machining operations where consistency and reliability are crucial. Chemical Synthesis Liquids are often used in industries where cleanliness and minimal residue are important, such as in electronics and medical device manufacturing. Semi-Synthetic Liquids, as the name suggests, are a hybrid between emulsions and synthetic fluids. They contain a lower percentage of oil compared to emulsions, combined with synthetic additives that enhance their performance. These fluids offer a balance between the cooling properties of water and the lubricating properties of oil, making them versatile for a wide range of applications. Semi-Synthetic Liquids are favored in industries that require both high performance and cost-effectiveness, such as machinery and mold processing. Each type of fluid has its unique advantages and is chosen based on the specific requirements of the machining operation, the materials being worked on, and the desired outcome. The choice of cutting fluid can significantly impact the efficiency, cost, and environmental footprint of manufacturing processes, making it a critical consideration for industries worldwide.

Automotive Manufacturing, Aerospace Manufacturing, Mold Processing Industry, Machinery Manufacturing, Shipbuilding Industry, Other in the Global Water-Based Cutting Fluids Market:

The usage of Global Water-Based Cutting Fluids Market spans across various industries, each with its unique requirements and challenges. In the automotive manufacturing sector, these fluids play a crucial role in the machining of engine components, transmission parts, and other critical components. The high-speed machining operations in this industry generate significant heat, and water-based cutting fluids are essential for cooling and lubricating the tools and workpieces. This not only extends the life of the cutting tools but also ensures the precision and quality of the finished components. In aerospace manufacturing, the demand for high-performance materials and precision machining is even more pronounced. Water-based cutting fluids are used extensively in the machining of aircraft components, where they help maintain tight tolerances and surface finishes. The aerospace industry also benefits from the environmental advantages of water-based fluids, as sustainability is a growing concern in this sector. The mold processing industry relies on water-based cutting fluids for the machining of molds used in plastic injection molding and die-casting. These fluids help achieve the required surface finish and dimensional accuracy, which are critical for the quality of the final products. In machinery manufacturing, water-based cutting fluids are used in the production of machine tools, industrial equipment, and other components. The versatility and cost-effectiveness of these fluids make them a popular choice in this industry. The shipbuilding industry also utilizes water-based cutting fluids in the machining of large metal components used in ship construction. The cooling and lubricating properties of these fluids are essential for the efficient machining of thick metal plates and other structural components. Other industries, such as electronics and medical device manufacturing, also benefit from the use of water-based cutting fluids, where cleanliness and precision are paramount. Overall, the Global Water-Based Cutting Fluids Market is integral to the efficiency and sustainability of manufacturing processes across a wide range of industries.

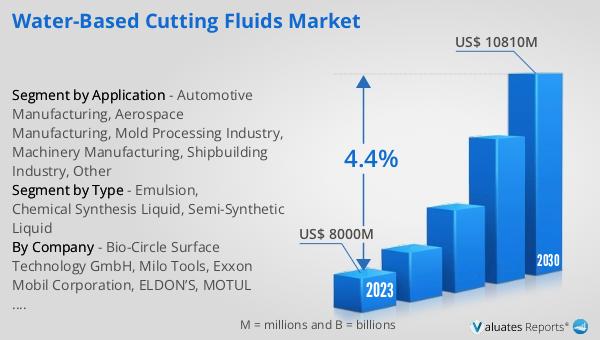

Global Water-Based Cutting Fluids Market Outlook:

The global market for Water-Based Cutting Fluids was valued at $8,683 million in 2024, with projections indicating a growth to $11,690 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.4% over the forecast period. This steady increase reflects the rising demand for efficient and environmentally friendly cutting fluids across various industries. The automotive and aerospace sectors, in particular, are driving this demand due to their need for high-performance machining solutions that can enhance productivity while minimizing environmental impact. The shift towards sustainable manufacturing practices is also contributing to the market's growth, as more companies seek to reduce their carbon footprint and comply with environmental regulations. Additionally, advancements in fluid technology are leading to the development of more effective and versatile water-based cutting fluids, further boosting their adoption. As industries continue to evolve and prioritize sustainability, the market for water-based cutting fluids is expected to expand, offering new opportunities for manufacturers and suppliers in this sector. The projected growth underscores the importance of these fluids in modern manufacturing processes and their role in supporting the transition to more sustainable industrial practices.

| Report Metric | Details |

| Report Name | Water-Based Cutting Fluids Market |

| Accounted market size in year | US$ 8683 million |

| Forecasted market size in 2031 | US$ 11690 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bio-Circle Surface Technology GmbH, Milo Tools, Exxon Mobil Corporation, ELDON’S, MOTUL TECH, Morris Lubricants, BP(Castrol), Quaker Houghton, COSMO Oil, Master, HAI LU JYA HE Co.,Ltd., MORESCO Corporation, Q8Oils, Millers Oils, CRC Industries, Benz, International Lubricants |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |