What is Global Aluminum and Composites for Aerospace Market?

The Global Aluminum and Composites for Aerospace Market is a specialized sector within the aerospace industry that focuses on the use of aluminum and composite materials in the construction and manufacturing of aircraft. These materials are crucial due to their lightweight properties, strength, and durability, which are essential for the performance and efficiency of modern aircraft. Aluminum has been a staple in aerospace manufacturing for decades due to its excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication. Composites, on the other hand, are increasingly being used because they offer even greater weight savings and can be engineered to meet specific performance requirements. The market for these materials is driven by the continuous demand for more fuel-efficient aircraft, which in turn reduces operational costs and environmental impact. As the aerospace industry evolves, the integration of advanced materials like aluminum and composites becomes more critical, supporting innovations in aircraft design and functionality. This market is not only significant for commercial aviation but also plays a vital role in military and space applications, where performance and reliability are paramount. The ongoing advancements in material science and engineering are expected to further enhance the capabilities and applications of aluminum and composites in the aerospace sector.

Aluminum, Composites in the Global Aluminum and Composites for Aerospace Market:

Aluminum and composites are two pivotal materials in the Global Aluminum and Composites for Aerospace Market, each offering unique benefits that cater to the demanding needs of the aerospace industry. Aluminum has long been a preferred material due to its lightweight nature, which is crucial for aircraft performance. Its high strength-to-weight ratio allows for the construction of robust yet lightweight structures, which is essential for fuel efficiency and payload capacity. Additionally, aluminum is highly resistant to corrosion, making it ideal for the harsh environments encountered during flight. It is also relatively easy to work with, allowing for the fabrication of complex shapes and structures necessary for modern aircraft design. On the other hand, composites are increasingly being adopted in aerospace applications due to their superior strength and stiffness compared to traditional materials. Composites are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, they produce a material with characteristics different from the individual components. This allows for the creation of materials that are tailored to specific performance requirements, such as increased strength, reduced weight, and enhanced durability. The use of composites in aerospace is driven by the need for lighter and more efficient aircraft. By reducing the weight of the aircraft, composites contribute to lower fuel consumption and emissions, which are critical factors in the industry's push towards sustainability. Furthermore, composites offer excellent fatigue resistance and can be designed to withstand the extreme conditions of flight, including high temperatures and pressures. The integration of composites into aircraft design also allows for greater flexibility in terms of shape and structure, enabling the development of more aerodynamic and efficient aircraft. The combination of aluminum and composites in aerospace applications represents a synergy of traditional and advanced materials, each complementing the other's strengths. While aluminum provides a reliable and proven foundation for aircraft structures, composites offer the potential for innovation and performance enhancement. This combination is particularly evident in the construction of aircraft fuselages, wings, and other critical components, where the balance of strength, weight, and durability is paramount. As the aerospace industry continues to evolve, the role of aluminum and composites is expected to grow, driven by advancements in material science and engineering. The ongoing research and development in this field aim to further enhance the properties and applications of these materials, supporting the industry's goals of increased efficiency, performance, and sustainability.

Commercial Aircraft, Military Aircraft, Helicopter in the Global Aluminum and Composites for Aerospace Market:

The usage of Global Aluminum and Composites for Aerospace Market materials is extensive across various types of aircraft, including commercial aircraft, military aircraft, and helicopters. In commercial aircraft, aluminum and composites are integral to the construction of the fuselage, wings, and tail sections. The lightweight nature of these materials is crucial for improving fuel efficiency, which is a significant concern for airlines looking to reduce operational costs and environmental impact. Composites, in particular, are used in the construction of modern commercial aircraft like the Boeing 787 and Airbus A350, where they contribute to significant weight savings and improved aerodynamics. The use of these materials also allows for the design of larger windows and more comfortable cabin environments, enhancing the passenger experience. In military aircraft, the demands for performance and durability are even more stringent. Aluminum and composites are used to construct airframes that can withstand the high stresses and extreme conditions encountered during combat and tactical operations. The lightweight properties of these materials enable military aircraft to achieve higher speeds and greater maneuverability, which are critical for mission success. Composites also offer stealth capabilities, as they can be engineered to absorb radar waves, reducing the aircraft's detectability. This is particularly important for modern fighter jets and reconnaissance aircraft, where stealth is a key operational requirement. Helicopters also benefit from the use of aluminum and composites, particularly in the construction of rotor blades and airframes. The lightweight nature of these materials is essential for the vertical lift capabilities of helicopters, allowing for greater payload capacity and improved fuel efficiency. Composites, with their high strength-to-weight ratio, are ideal for rotor blades, which must withstand significant aerodynamic forces while maintaining structural integrity. The use of these materials also contributes to reduced vibration and noise levels, enhancing the comfort and safety of helicopter operations. Overall, the application of aluminum and composites in aerospace is driven by the need for improved performance, efficiency, and sustainability across all types of aircraft. As the aerospace industry continues to advance, the integration of these materials is expected to expand, supported by ongoing research and development efforts aimed at enhancing their properties and applications.

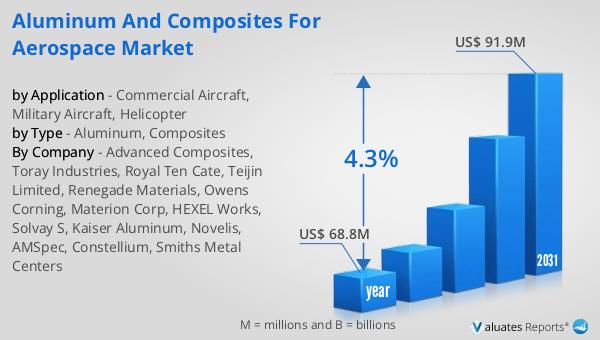

Global Aluminum and Composites for Aerospace Market Outlook:

The outlook for the Global Aluminum and Composites for Aerospace Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 68.8 million. Looking ahead, it is anticipated to expand significantly, reaching an estimated size of US$ 91.9 million by the year 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.3% over the forecast period. This upward trend reflects the increasing demand for lightweight and efficient materials in the aerospace industry, driven by the need for more fuel-efficient and environmentally friendly aircraft. The adoption of aluminum and composites is set to rise as manufacturers seek to enhance aircraft performance and reduce operational costs. The market's expansion is also supported by advancements in material science and engineering, which are continually improving the properties and applications of these materials. As the aerospace industry evolves, the role of aluminum and composites is expected to become even more critical, supporting innovations in aircraft design and functionality. This growth outlook underscores the importance of these materials in meeting the industry's goals of increased efficiency, performance, and sustainability.

| Report Metric | Details |

| Report Name | Aluminum and Composites for Aerospace Market |

| Accounted market size in year | US$ 68.8 million |

| Forecasted market size in 2031 | US$ 91.9 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Advanced Composites, Toray Industries, Royal Ten Cate, Teijin Limited, Renegade Materials, Owens Corning, Materion Corp, HEXEL Works, Solvay S, Kaiser Aluminum, Novelis, AMSpec, Constellium, Smiths Metal Centers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |