What is Global High-purity Isotopic Copper Powder Market?

The Global High-purity Isotopic Copper Powder Market is a specialized segment within the broader copper industry, focusing on the production and distribution of copper powder with extremely high isotopic purity. This market caters to industries that require copper with specific isotopic compositions, which can significantly enhance the performance and efficiency of various applications. High-purity isotopic copper powder is produced through advanced techniques that ensure the removal of impurities and the precise control of isotopic ratios. This level of purity is crucial for applications in high-tech industries, including electronics, where even minor impurities can affect conductivity and performance. The demand for high-purity isotopic copper powder is driven by its unique properties, such as enhanced electrical conductivity, thermal stability, and compatibility with other materials. As industries continue to innovate and develop new technologies, the need for materials that can meet stringent performance criteria is increasing, making high-purity isotopic copper powder an essential component in the advancement of modern technology.

6N, 7N, Others in the Global High-purity Isotopic Copper Powder Market:

In the Global High-purity Isotopic Copper Powder Market, the terms 6N, 7N, and others refer to the purity levels of the copper powder, with each designation indicating a different degree of purity. The "N" in these terms stands for "nines," which is a way of expressing the purity level in terms of the number of nines in the percentage of purity. For instance, 6N copper powder has a purity of 99.9999%, while 7N copper powder boasts an even higher purity of 99.99999%. These high levels of purity are achieved through meticulous production processes that involve multiple stages of refinement and purification. The 6N copper powder is often used in applications where high electrical conductivity and minimal impurities are essential, such as in the manufacturing of semiconductors and other electronic components. Its high purity ensures that the copper does not introduce any unwanted variables into the delicate processes involved in semiconductor fabrication. On the other hand, 7N copper powder is used in even more demanding applications, where the absolute highest level of purity is required. This includes advanced scientific research, where the presence of even the smallest impurity could skew results or affect the performance of experimental setups. The production of 7N copper powder is a complex and costly process, involving state-of-the-art technology and rigorous quality control measures to ensure that the final product meets the stringent purity requirements. Beyond 6N and 7N, there are other purity levels available in the market, each catering to specific needs and applications. These other grades of high-purity isotopic copper powder are used in a variety of industries, including aerospace, medical devices, and high-precision engineering. The choice of purity level depends on the specific requirements of the application, with higher purity levels generally commanding a premium price due to the increased complexity and cost of production. As technology continues to advance, the demand for high-purity isotopic copper powder is expected to grow, driven by the need for materials that can meet the increasingly stringent performance standards of modern applications. The market for these materials is characterized by a high degree of specialization, with manufacturers focusing on developing innovative production techniques to achieve the desired purity levels. This has led to a competitive landscape, where companies are constantly striving to improve their processes and offer products that meet the evolving needs of their customers. In summary, the Global High-purity Isotopic Copper Powder Market is defined by the pursuit of ever-higher purity levels, with 6N and 7N copper powders representing the pinnacle of current production capabilities. These materials are essential for a wide range of high-tech applications, and their importance is only set to increase as industries continue to push the boundaries of what is possible with advanced materials.

Electronics, Chemical Industry, Others in the Global High-purity Isotopic Copper Powder Market:

The Global High-purity Isotopic Copper Powder Market finds its applications across various sectors, with electronics and the chemical industry being two of the most significant. In the electronics sector, high-purity isotopic copper powder is indispensable due to its superior electrical conductivity and minimal impurity levels. It is used in the production of semiconductors, printed circuit boards (PCBs), and other electronic components where precision and reliability are paramount. The high purity of the copper powder ensures that the electronic components function optimally, with reduced risk of failure due to impurities that could interfere with electrical signals. This is particularly important in the production of high-performance computing devices, smartphones, and other consumer electronics, where even the slightest deviation in material quality can lead to significant performance issues. In the chemical industry, high-purity isotopic copper powder is used as a catalyst in various chemical reactions. Its high surface area and purity make it an ideal choice for facilitating reactions that require precise control over reaction conditions and outcomes. The use of high-purity copper powder as a catalyst can lead to more efficient chemical processes, with higher yields and fewer by-products. This is particularly valuable in the production of fine chemicals, pharmaceuticals, and other high-value products where purity and efficiency are critical. Beyond electronics and the chemical industry, high-purity isotopic copper powder is also used in other sectors, such as aerospace and medical devices. In aerospace, the material's high thermal and electrical conductivity, combined with its low weight, make it an ideal choice for use in advanced avionics and other critical systems. In the medical field, high-purity copper powder is used in the production of medical devices and implants, where biocompatibility and precision are essential. The ability to produce copper powder with specific isotopic compositions also opens up new possibilities for research and development in fields such as nuclear medicine and advanced materials science. As industries continue to evolve and demand more from their materials, the role of high-purity isotopic copper powder is set to become even more critical. Its unique properties make it an essential component in the development of new technologies and processes, driving innovation and progress across a wide range of applications.

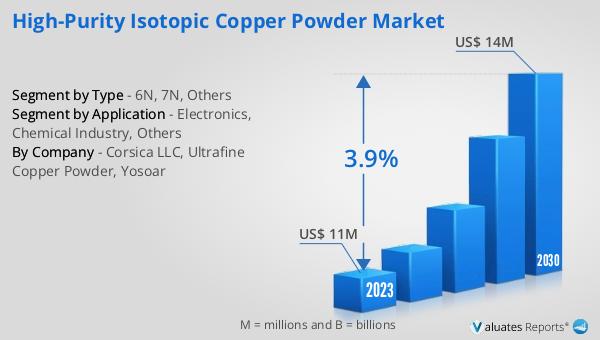

Global High-purity Isotopic Copper Powder Market Outlook:

The global market for High-purity Isotopic Copper Powder was valued at $11.7 million in 2024, and it is anticipated to expand to a revised size of $15.2 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. This growth trajectory underscores the increasing demand for high-purity isotopic copper powder across various industries, driven by its unique properties and the critical role it plays in advanced technological applications. The market's expansion is indicative of the broader trend towards the use of high-performance materials that can meet the stringent requirements of modern industries. As the demand for high-tech electronics, efficient chemical processes, and advanced medical devices continues to rise, so too does the need for materials that can deliver the necessary performance and reliability. The projected growth of the high-purity isotopic copper powder market is a testament to the material's importance in these sectors, as well as its potential to drive further innovation and development. The market's steady growth rate reflects the ongoing efforts of manufacturers to improve production processes and develop new applications for high-purity isotopic copper powder, ensuring that it remains a vital component in the advancement of technology and industry.

| Report Metric | Details |

| Report Name | High-purity Isotopic Copper Powder Market |

| Accounted market size in year | US$ 11.7 million |

| Forecasted market size in 2031 | US$ 15.2 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Corsica LLC, Ultrafine Copper Powder, Yosoar |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |