What is Global Foam Bonding Tapes Market?

The Global Foam Bonding Tapes Market is a specialized segment within the adhesive industry, focusing on tapes that utilize foam as a core component to provide bonding solutions across various applications. These tapes are engineered to offer excellent adhesion properties, cushioning, and gap-filling capabilities, making them ideal for a wide range of industrial and commercial uses. Foam bonding tapes are typically made from materials such as polyethylene, polyurethane, or acrylic, which are known for their durability and flexibility. They are used in applications where traditional fasteners or liquid adhesives might not be suitable, providing a clean and efficient alternative. The market for these tapes is driven by their versatility and the growing demand in sectors such as automotive, construction, and electronics, where they are used for mounting, sealing, and vibration damping. As industries continue to seek more efficient and cost-effective bonding solutions, the demand for foam bonding tapes is expected to grow, supported by advancements in material technology and manufacturing processes. This market is characterized by a diverse range of products tailored to meet specific application needs, with manufacturers focusing on innovation to enhance performance and environmental sustainability.

Single Sided, Double Sided in the Global Foam Bonding Tapes Market:

In the Global Foam Bonding Tapes Market, products are primarily categorized into single-sided and double-sided tapes, each serving distinct purposes and applications. Single-sided foam bonding tapes have adhesive on one side of the foam substrate, making them suitable for applications where only one surface needs to be bonded. These tapes are often used for cushioning, sealing, and insulating purposes. For instance, in the automotive industry, single-sided tapes are employed to reduce noise and vibration by acting as a barrier between components. They are also used in construction for sealing windows and doors, providing a weather-resistant barrier that helps in energy conservation. The adhesive used in single-sided tapes is typically pressure-sensitive, allowing for easy application and repositioning if necessary. On the other hand, double-sided foam bonding tapes have adhesive on both sides of the foam substrate, offering a strong bond between two surfaces. This makes them ideal for applications requiring a permanent bond, such as mounting mirrors, signs, and panels. In the electronics industry, double-sided tapes are used for assembling components, providing a clean and efficient alternative to liquid adhesives. The choice between single-sided and double-sided tapes depends on the specific requirements of the application, including the type of surfaces to be bonded, the environmental conditions, and the desired strength of the bond. Manufacturers offer a wide range of options in terms of thickness, adhesive type, and foam material to cater to diverse needs. For example, acrylic adhesives are known for their excellent UV resistance and durability, making them suitable for outdoor applications, while rubber-based adhesives offer superior initial tack and are often used for indoor applications. The foam material itself can also vary, with options such as polyethylene foam providing excellent cushioning and vibration damping, while polyurethane foam offers superior flexibility and conformability. As industries continue to evolve, the demand for both single-sided and double-sided foam bonding tapes is expected to grow, driven by the need for efficient and reliable bonding solutions. Manufacturers are investing in research and development to enhance the performance of these tapes, focusing on improving adhesion properties, environmental resistance, and ease of application. Additionally, there is a growing emphasis on sustainability, with companies exploring eco-friendly materials and production processes to reduce the environmental impact of their products. This focus on innovation and sustainability is expected to shape the future of the Global Foam Bonding Tapes Market, providing new opportunities for growth and development.

Automotive, Electrical, Other in the Global Foam Bonding Tapes Market:

The usage of Global Foam Bonding Tapes Market spans across various industries, with significant applications in the automotive, electrical, and other sectors. In the automotive industry, foam bonding tapes are used extensively for their ability to provide strong adhesion, noise reduction, and vibration damping. They are employed in the assembly of interior components, such as dashboards and door panels, where they help to reduce rattling and improve the overall comfort of the vehicle. Additionally, these tapes are used for mounting emblems, trim, and other exterior components, providing a clean and efficient alternative to mechanical fasteners. The ability of foam bonding tapes to withstand harsh environmental conditions, such as temperature fluctuations and exposure to moisture, makes them ideal for automotive applications. In the electrical industry, foam bonding tapes are used for insulating and protecting components, providing a barrier against dust, moisture, and other contaminants. They are employed in the assembly of electronic devices, where they help to secure components and prevent short circuits. The flexibility and conformability of foam bonding tapes make them suitable for use in complex assemblies, where they can be easily applied to irregular surfaces. Additionally, these tapes are used for cable management, providing a neat and organized solution for bundling and securing wires. Beyond automotive and electrical applications, foam bonding tapes are used in a variety of other industries, including construction, healthcare, and packaging. In construction, they are employed for sealing windows and doors, providing a weather-resistant barrier that helps to improve energy efficiency. In healthcare, foam bonding tapes are used for securing medical devices and equipment, offering a gentle and skin-friendly alternative to traditional adhesives. In the packaging industry, these tapes are used for securing and cushioning products during transit, providing protection against damage. The versatility and performance of foam bonding tapes make them an essential component in many industrial and commercial applications. As industries continue to seek more efficient and cost-effective bonding solutions, the demand for foam bonding tapes is expected to grow, driven by advancements in material technology and manufacturing processes. Manufacturers are focusing on innovation to enhance the performance of these tapes, exploring new materials and adhesive formulations to meet the evolving needs of their customers. Additionally, there is a growing emphasis on sustainability, with companies exploring eco-friendly materials and production processes to reduce the environmental impact of their products. This focus on innovation and sustainability is expected to shape the future of the Global Foam Bonding Tapes Market, providing new opportunities for growth and development.

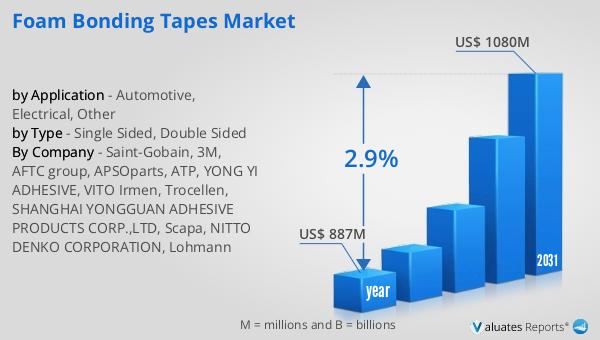

Global Foam Bonding Tapes Market Outlook:

The global market for foam bonding tapes was valued at $887 million in 2024, and it is anticipated to expand to a revised size of $1,080 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.9% over the forecast period. This growth trajectory underscores the increasing demand for foam bonding tapes across various industries, driven by their versatility and efficiency as bonding solutions. The market's expansion is fueled by the rising adoption of these tapes in sectors such as automotive, construction, and electronics, where they offer advantages such as strong adhesion, noise reduction, and vibration damping. As industries continue to evolve and seek more efficient and cost-effective bonding solutions, the demand for foam bonding tapes is expected to grow, supported by advancements in material technology and manufacturing processes. Manufacturers are focusing on innovation to enhance the performance of these tapes, exploring new materials and adhesive formulations to meet the evolving needs of their customers. Additionally, there is a growing emphasis on sustainability, with companies exploring eco-friendly materials and production processes to reduce the environmental impact of their products. This focus on innovation and sustainability is expected to shape the future of the Global Foam Bonding Tapes Market, providing new opportunities for growth and development.

| Report Metric | Details |

| Report Name | Foam Bonding Tapes Market |

| Accounted market size in year | US$ 887 million |

| Forecasted market size in 2031 | US$ 1080 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Saint-Gobain, 3M, AFTC group, APSOparts, ATP, YONG YI ADHESIVE, VITO Irmen, Trocellen, SHANGHAI YONGGUAN ADHESIVE PRODUCTS CORP.,LTD, Scapa, NITTO DENKO CORPORATION, Lohmann |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |