What is Global Solvent-Based Aerospace Coatings Market?

The Global Solvent-Based Aerospace Coatings Market is a specialized segment within the broader aerospace coatings industry, focusing on coatings that utilize solvents as a primary component. These coatings are essential for protecting aircraft surfaces from environmental factors such as corrosion, UV radiation, and wear and tear. Solvent-based coatings are preferred in many aerospace applications due to their durability, ease of application, and ability to form a robust protective layer. They are particularly effective in harsh environments where aircraft are exposed to extreme temperatures and weather conditions. The market for these coatings is driven by the increasing demand for new aircraft, the need for maintenance and repair of existing fleets, and advancements in coating technologies that enhance performance and reduce environmental impact. As the aerospace industry continues to grow, particularly in emerging markets, the demand for high-quality solvent-based coatings is expected to rise, making this a critical area of focus for manufacturers and suppliers. The market is characterized by a mix of established players and new entrants, all striving to innovate and meet the evolving needs of the aerospace sector.

Aerospace Interior Coating, Aerospace Exterior Coating in the Global Solvent-Based Aerospace Coatings Market:

Aerospace coatings are divided into two main categories: interior and exterior coatings, each serving distinct purposes within the Global Solvent-Based Aerospace Coatings Market. Aerospace interior coatings are designed to enhance the aesthetics and functionality of an aircraft's interior. These coatings must meet stringent safety standards, including fire resistance and low toxicity, to ensure passenger safety. They are used on various surfaces such as cabin walls, seats, and overhead compartments, providing a pleasing appearance while protecting against wear and tear. The coatings must also withstand frequent cleaning and exposure to different chemicals without degrading. On the other hand, aerospace exterior coatings are crucial for protecting the aircraft's outer surfaces from environmental damage. These coatings must be highly durable to withstand extreme temperatures, UV radiation, and the mechanical stresses of flight. They also play a role in reducing drag and improving fuel efficiency by providing a smooth surface. Solvent-based exterior coatings are particularly valued for their strong adhesion and resistance to harsh conditions. The application of these coatings involves several layers, including primers, topcoats, and sometimes special coatings for specific functions like anti-static or anti-icing. The choice of coating depends on the aircraft type, its operational environment, and regulatory requirements. Both interior and exterior coatings are subject to rigorous testing to ensure they meet industry standards and provide long-lasting protection. As technology advances, there is a growing trend towards developing coatings that are not only more effective but also environmentally friendly, with reduced volatile organic compounds (VOCs) and improved sustainability. This shift is driven by regulatory pressures and the aerospace industry's commitment to reducing its environmental footprint. Manufacturers are investing in research and development to create innovative solutions that balance performance with environmental considerations. The market for solvent-based aerospace coatings is highly competitive, with companies striving to differentiate themselves through product innovation, quality, and customer service. As the demand for new aircraft and maintenance services continues to grow, the importance of high-performance coatings in ensuring the safety, efficiency, and longevity of aircraft cannot be overstated.

Civil Aviation, Military Aviation in the Global Solvent-Based Aerospace Coatings Market:

The Global Solvent-Based Aerospace Coatings Market plays a vital role in both civil and military aviation, providing essential protection and performance enhancements for a wide range of aircraft. In civil aviation, these coatings are used extensively on commercial airliners, private jets, and cargo planes. The primary function of solvent-based coatings in this sector is to protect the aircraft from environmental damage, such as corrosion, UV radiation, and extreme weather conditions. This protection is crucial for maintaining the structural integrity and appearance of the aircraft, which in turn affects its operational efficiency and lifespan. Additionally, these coatings contribute to fuel efficiency by reducing drag, which is a significant consideration for airlines looking to minimize operational costs and environmental impact. In military aviation, the requirements for aerospace coatings are even more demanding. Military aircraft operate in some of the harshest environments and are subject to rigorous performance standards. Solvent-based coatings used in this sector must provide exceptional durability and resistance to extreme conditions, including high-speed flight, rapid temperature changes, and exposure to various chemicals and fuels. These coatings also play a critical role in camouflage and stealth technologies, helping military aircraft avoid detection and enhance their operational capabilities. The coatings must adhere to strict military specifications, ensuring they meet the necessary performance and safety standards. In both civil and military aviation, the application of solvent-based coatings involves a complex process that requires specialized equipment and skilled technicians. The coatings are applied in multiple layers, each serving a specific function, from primers that enhance adhesion to topcoats that provide the final protective barrier. The choice of coating system depends on various factors, including the aircraft type, its operational environment, and regulatory requirements. As the aerospace industry continues to evolve, there is an increasing focus on developing coatings that offer improved performance while minimizing environmental impact. This includes reducing the use of volatile organic compounds (VOCs) and developing more sustainable coating solutions. The Global Solvent-Based Aerospace Coatings Market is poised for growth as the demand for new aircraft and maintenance services increases, driven by factors such as rising air travel, fleet expansion, and the need for modernization in both civil and military aviation.

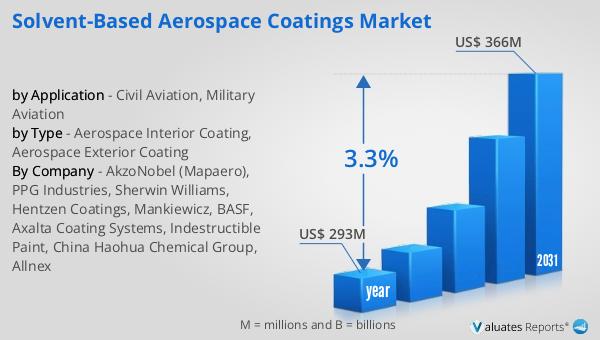

Global Solvent-Based Aerospace Coatings Market Outlook:

The global market for solvent-based aerospace coatings was valued at approximately $293 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $366 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.3% over the forecast period. The market's expansion is driven by several factors, including the increasing demand for new aircraft, the need for maintenance and repair of existing fleets, and advancements in coating technologies. As the aerospace industry continues to grow, particularly in emerging markets, the demand for high-quality solvent-based coatings is expected to rise. These coatings are essential for protecting aircraft surfaces from environmental factors such as corrosion, UV radiation, and wear and tear. Solvent-based coatings are preferred in many aerospace applications due to their durability, ease of application, and ability to form a robust protective layer. The market is characterized by a mix of established players and new entrants, all striving to innovate and meet the evolving needs of the aerospace sector. As technology advances, there is a growing trend towards developing coatings that are not only more effective but also environmentally friendly, with reduced volatile organic compounds (VOCs) and improved sustainability. This shift is driven by regulatory pressures and the aerospace industry's commitment to reducing its environmental footprint. Manufacturers are investing in research and development to create innovative solutions that balance performance with environmental considerations. The market for solvent-based aerospace coatings is highly competitive, with companies striving to differentiate themselves through product innovation, quality, and customer service. As the demand for new aircraft and maintenance services continues to grow, the importance of high-performance coatings in ensuring the safety, efficiency, and longevity of aircraft cannot be overstated.

| Report Metric | Details |

| Report Name | Solvent-Based Aerospace Coatings Market |

| Accounted market size in year | US$ 293 million |

| Forecasted market size in 2031 | US$ 366 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AkzoNobel (Mapaero), PPG Industries, Sherwin Williams, Hentzen Coatings, Mankiewicz, BASF, Axalta Coating Systems, Indestructible Paint, China Haohua Chemical Group, Allnex |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |