What is Global Zinc Stearate Dispersion Market?

The Global Zinc Stearate Dispersion Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of zinc stearate dispersions. Zinc stearate is a compound formed from zinc and stearic acid, known for its lubricating properties and water-repellent characteristics. In dispersion form, it is used in various industries due to its ability to enhance the texture and performance of products. The market for zinc stearate dispersion is driven by its applications in plastics, rubber, coatings, and cosmetics, among others. These dispersions are particularly valued for their role as release agents, stabilizers, and anti-caking agents. The demand for zinc stearate dispersion is influenced by the growth of end-user industries, technological advancements, and the increasing need for high-performance materials. As industries continue to seek materials that improve product quality and manufacturing efficiency, the zinc stearate dispersion market is expected to grow, adapting to new applications and regulatory standards. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the properties and applications of zinc stearate dispersions. Overall, the Global Zinc Stearate Dispersion Market plays a crucial role in supporting various industrial processes and product innovations.

30% Purity, 45% Purity, Other in the Global Zinc Stearate Dispersion Market:

In the Global Zinc Stearate Dispersion Market, purity levels such as 30% and 45% are significant as they determine the concentration of zinc stearate in the dispersion, impacting its effectiveness and suitability for different applications. A 30% purity level indicates that the dispersion contains 30% zinc stearate, with the remaining 70% comprising other components such as solvents or carriers. This level of purity is often used in applications where a moderate concentration of zinc stearate is sufficient to achieve the desired properties, such as in certain plastic and rubber formulations. The 30% purity dispersions are typically more cost-effective and are chosen for applications where high concentrations are not necessary, providing a balance between performance and cost. On the other hand, a 45% purity level means that the dispersion contains a higher concentration of zinc stearate, making it more potent and suitable for applications requiring enhanced performance. This higher purity level is often preferred in industries where the dispersion's lubricating, anti-caking, or stabilizing properties need to be maximized, such as in high-performance coatings or advanced rubber products. The choice between 30% and 45% purity levels depends on the specific requirements of the application, including the desired performance characteristics, cost considerations, and compatibility with other materials. Additionally, there are other purity levels available in the market, catering to niche applications or specific industry needs. These variations allow manufacturers to tailor the properties of zinc stearate dispersions to meet the diverse demands of different sectors. The availability of multiple purity levels in the Global Zinc Stearate Dispersion Market highlights the versatility and adaptability of these products, enabling them to support a wide range of industrial processes and innovations. As industries continue to evolve and seek materials that enhance product quality and manufacturing efficiency, the demand for zinc stearate dispersions with varying purity levels is expected to grow, driving further advancements and applications in this market.

Architecture, Papermaking, Other in the Global Zinc Stearate Dispersion Market:

The Global Zinc Stearate Dispersion Market finds extensive usage in various sectors, including architecture, papermaking, and other industries, due to its versatile properties. In the field of architecture, zinc stearate dispersions are primarily used in coatings and paints. They act as excellent flatting agents, providing a matte finish to surfaces, which is often desired in architectural applications. Additionally, zinc stearate dispersions enhance the water-repellent properties of coatings, making them suitable for exterior applications where protection against moisture is crucial. The dispersions also improve the durability and longevity of coatings, ensuring that architectural structures maintain their aesthetic appeal and structural integrity over time. In papermaking, zinc stearate dispersions are used as lubricants and anti-caking agents. They help in the smooth processing of paper by reducing friction between the paper and machinery, thereby preventing jams and ensuring efficient production. The anti-caking properties of zinc stearate dispersions also prevent the paper from sticking together, maintaining its quality and usability. Furthermore, these dispersions contribute to the paper's surface properties, enhancing its printability and overall appearance. Beyond architecture and papermaking, zinc stearate dispersions are utilized in various other industries, including plastics, rubber, and cosmetics. In the plastics industry, they serve as release agents, facilitating the easy removal of molded products from molds without damaging the surface. This property is particularly valuable in the production of intricate plastic components where precision and surface quality are critical. In the rubber industry, zinc stearate dispersions act as processing aids, improving the flow and moldability of rubber compounds. They also enhance the heat resistance and mechanical properties of rubber products, making them suitable for demanding applications. In the cosmetics industry, zinc stearate dispersions are used in formulations to improve the texture and spreadability of products, providing a smooth and silky feel on the skin. The versatility of zinc stearate dispersions in these diverse applications underscores their importance in enhancing product performance and manufacturing efficiency across various sectors. As industries continue to innovate and seek materials that offer superior properties, the usage of zinc stearate dispersions is expected to expand, driving further growth and development in the Global Zinc Stearate Dispersion Market.

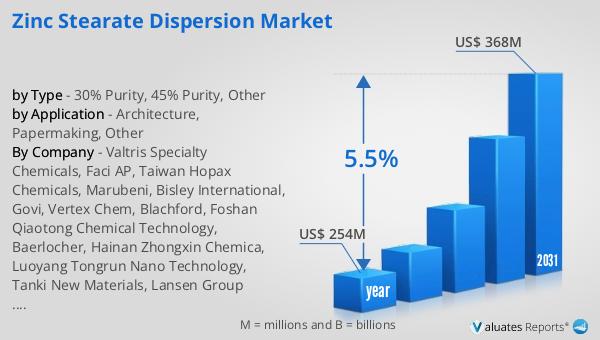

Global Zinc Stearate Dispersion Market Outlook:

The global market for Zinc Stearate Dispersion, initially valued at $254 million in 2024, is anticipated to grow significantly, reaching an estimated $368 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.5% over the forecast period. The market's expansion is driven by increasing demand across various industries, including plastics, rubber, coatings, and cosmetics, where zinc stearate dispersions are valued for their unique properties. These dispersions play a crucial role in enhancing product performance, improving manufacturing efficiency, and meeting the evolving needs of end-user industries. The projected growth reflects the market's adaptability to changing industry trends and technological advancements, as well as its ability to cater to the diverse requirements of different sectors. As industries continue to seek high-performance materials that offer superior properties, the demand for zinc stearate dispersions is expected to rise, supporting the market's growth. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the properties and applications of zinc stearate dispersions, ensuring that they remain relevant and valuable in a rapidly evolving industrial landscape. Overall, the Global Zinc Stearate Dispersion Market is poised for significant growth, driven by its versatility, adaptability, and ability to meet the diverse needs of various industries.

| Report Metric | Details |

| Report Name | Zinc Stearate Dispersion Market |

| Accounted market size in year | US$ 254 million |

| Forecasted market size in 2031 | US$ 368 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Valtris Specialty Chemicals, Faci AP, Taiwan Hopax Chemicals, Marubeni, Bisley International, Govi, Vertex Chem, Blachford, Foshan Qiaotong Chemical Technology, Baerlocher, Hainan Zhongxin Chemica, Luoyang Tongrun Nano Technology, Tanki New Materials, Lansen Group International, Peter Greven |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |