What is Global Carbon Fiber Soft Felt Market?

The Global Carbon Fiber Soft Felt Market is a specialized segment within the broader carbon fiber industry, focusing on the production and application of soft felt materials made from carbon fibers. These materials are known for their lightweight, high thermal insulation, and excellent electrical conductivity properties. Carbon fiber soft felt is primarily used in high-temperature environments due to its ability to withstand extreme heat without degrading. It is also valued for its chemical resistance and low thermal expansion, making it suitable for various industrial applications. The market for carbon fiber soft felt is driven by the increasing demand for advanced materials in industries such as aerospace, automotive, and energy. As these industries continue to seek materials that offer superior performance while reducing weight and improving energy efficiency, the demand for carbon fiber soft felt is expected to grow. Additionally, the push for sustainable and environmentally friendly materials is further propelling the market, as carbon fiber soft felt can contribute to reducing the carbon footprint of various applications. Overall, the Global Carbon Fiber Soft Felt Market is poised for growth as industries continue to innovate and seek out materials that meet their evolving needs.

Pan-Based Carbon Fiber, Rayon-Based Carbon Fiber, Pitch-Based Carbon Fiber in the Global Carbon Fiber Soft Felt Market:

Pan-Based Carbon Fiber, Rayon-Based Carbon Fiber, and Pitch-Based Carbon Fiber are three primary types of carbon fibers used in the Global Carbon Fiber Soft Felt Market, each with distinct characteristics and applications. Pan-Based Carbon Fiber is derived from polyacrylonitrile (PAN) and is the most widely used type due to its high tensile strength and modulus. It is favored in applications requiring lightweight and high-strength materials, such as aerospace and automotive industries. The production process involves stabilizing and carbonizing PAN fibers, resulting in a material that offers excellent mechanical properties and thermal stability. Rayon-Based Carbon Fiber, on the other hand, is made from regenerated cellulose fibers. Although it is less common than PAN-based fibers, it is valued for its superior thermal insulation properties. This type of carbon fiber is often used in applications where high thermal resistance is crucial, such as in high-temperature furnace linings and thermal insulation for aerospace components. The production process for rayon-based carbon fibers involves carbonizing rayon fibers, which results in a material with a lower density and higher thermal insulation compared to PAN-based fibers. Pitch-Based Carbon Fiber is derived from petroleum or coal tar pitch and is known for its high modulus and thermal conductivity. It is used in applications that require materials with high stiffness and thermal management capabilities, such as in electronic devices and heat sinks. The production process involves spinning pitch into fibers, followed by stabilization and carbonization, resulting in a material with unique properties that make it suitable for specialized applications. Each type of carbon fiber offers distinct advantages, and the choice of fiber depends on the specific requirements of the application. The Global Carbon Fiber Soft Felt Market benefits from the diversity of these fibers, as they provide a range of options for industries seeking advanced materials with tailored properties.

Stationary Energy Storage Batteries, High Temperature Furnace Linings, Acid Gas Mist Eliminators, Carbon Composite Materials, Other in the Global Carbon Fiber Soft Felt Market:

The Global Carbon Fiber Soft Felt Market finds applications in various areas, including Stationary Energy Storage Batteries, High Temperature Furnace Linings, Acid Gas Mist Eliminators, Carbon Composite Materials, and others. In Stationary Energy Storage Batteries, carbon fiber soft felt is used as an electrode material due to its excellent electrical conductivity and lightweight properties. This application is crucial for improving the efficiency and performance of energy storage systems, which are essential for renewable energy integration and grid stability. In High Temperature Furnace Linings, carbon fiber soft felt is valued for its thermal insulation properties, which help maintain high temperatures while minimizing heat loss. This application is critical in industries such as metallurgy and ceramics, where maintaining consistent high temperatures is necessary for production processes. Acid Gas Mist Eliminators utilize carbon fiber soft felt for its chemical resistance and ability to capture fine particles and mist. This application is important in industries that deal with corrosive gases, as it helps protect equipment and reduce emissions. Carbon Composite Materials benefit from the lightweight and high-strength properties of carbon fiber soft felt, making them ideal for use in aerospace, automotive, and sports equipment. These materials offer improved performance and fuel efficiency, contributing to the overall sustainability of these industries. Other applications of carbon fiber soft felt include its use in filtration systems, thermal insulation for electronic devices, and as a reinforcement material in various industrial applications. The versatility and unique properties of carbon fiber soft felt make it a valuable material across multiple industries, driving its demand in the global market.

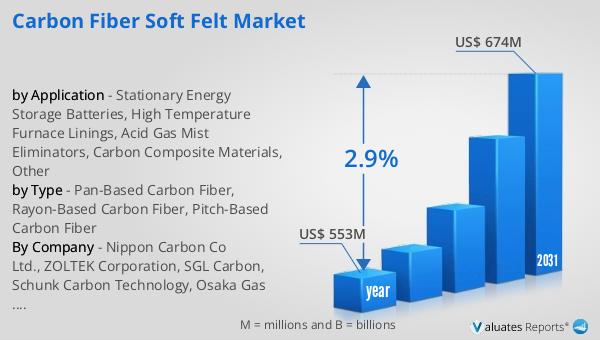

Global Carbon Fiber Soft Felt Market Outlook:

The global market for Carbon Fiber Soft Felt was valued at $553 million in 2024, with projections indicating it will reach approximately $674 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.9% over the forecast period. The steady increase in market size reflects the rising demand for carbon fiber soft felt across various industries, driven by the need for advanced materials that offer superior performance and sustainability. As industries continue to innovate and seek out materials that meet their evolving needs, the demand for carbon fiber soft felt is expected to grow. The market's expansion is also supported by the increasing focus on reducing carbon footprints and improving energy efficiency, as carbon fiber soft felt can contribute to these goals. Additionally, the push for sustainable and environmentally friendly materials is further propelling the market, as carbon fiber soft felt can contribute to reducing the carbon footprint of various applications. Overall, the Global Carbon Fiber Soft Felt Market is poised for growth as industries continue to innovate and seek out materials that meet their evolving needs.

| Report Metric | Details |

| Report Name | Carbon Fiber Soft Felt Market |

| Accounted market size in year | US$ 553 million |

| Forecasted market size in 2031 | US$ 674 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nippon Carbon Co Ltd., ZOLTEK Corporation, SGL Carbon, Schunk Carbon Technology, Osaka Gas Chemicals Co., Ltd., Kureha Corporation, Beijing Great Wall Co., Ltd., CFC Carbon Co. LTD., Sinotek Materials Co., Olmec Advanced Materials, Mersen Graphite |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |