What is Global Eco-Friendly Cutting Fluid Market?

The Global Eco-Friendly Cutting Fluid Market is a rapidly evolving sector that focuses on providing sustainable and environmentally friendly solutions for industrial machining processes. Cutting fluids, also known as coolants or lubricants, are essential in various manufacturing operations to reduce heat and friction between cutting tools and workpieces. Traditionally, these fluids have been petroleum-based, which poses environmental and health concerns due to their non-biodegradable nature and potential to release harmful substances. The eco-friendly cutting fluid market addresses these issues by offering alternatives that are biodegradable, non-toxic, and derived from renewable resources. These fluids not only help in minimizing the environmental footprint but also enhance the safety and health conditions in workplaces. The demand for eco-friendly cutting fluids is driven by stringent environmental regulations, increasing awareness about sustainable practices, and the growing emphasis on corporate social responsibility. Industries across the globe are adopting these green solutions to align with global sustainability goals and to improve their operational efficiency. As a result, the market is witnessing significant growth, with innovations and advancements in product formulations that cater to diverse industrial needs. The shift towards eco-friendly cutting fluids is not just a trend but a necessary evolution in the manufacturing landscape.

Straight Oil, Water in the Global Eco-Friendly Cutting Fluid Market:

Straight oil and water-based fluids are two primary categories within the Global Eco-Friendly Cutting Fluid Market, each offering distinct advantages and applications. Straight oils are non-emulsifiable and are used in their pure form. They are primarily composed of mineral oils, although eco-friendly variants are increasingly being developed using vegetable oils or synthetic esters. These oils provide excellent lubrication, which is crucial for heavy-duty machining operations where high levels of friction and heat are generated. Straight oils are particularly effective in applications requiring superior surface finishes and extended tool life. However, their use is often limited by their poor cooling properties and potential for smoke generation, which can be mitigated by using eco-friendly formulations that reduce environmental impact and improve workplace safety. On the other hand, water-based cutting fluids, which include soluble oils, semi-synthetics, and synthetics, are more versatile and widely used due to their excellent cooling capabilities. Soluble oils form an emulsion when mixed with water, providing a balance between lubrication and cooling. Semi-synthetics are a hybrid of soluble oils and synthetics, offering enhanced performance with lower oil content. Synthetics, which are entirely oil-free, provide superior cooling and are ideal for high-speed machining operations. The eco-friendly versions of these water-based fluids are designed to be biodegradable and free from harmful additives, making them safer for both the environment and workers. The choice between straight oil and water-based fluids depends on the specific requirements of the machining process, such as the material being machined, the type of operation, and the desired balance between cooling and lubrication. As industries continue to prioritize sustainability, the development and adoption of eco-friendly cutting fluids are expected to grow, with ongoing research focused on improving their performance and reducing their environmental impact. This shift not only supports environmental goals but also enhances operational efficiency and cost-effectiveness in the long run.

Mechanical, The Automobile, 3C Electronic, Other in the Global Eco-Friendly Cutting Fluid Market:

The usage of Global Eco-Friendly Cutting Fluid Market spans across various industries, including mechanical, automobile, 3C electronic, and others, each with unique requirements and benefits. In the mechanical industry, eco-friendly cutting fluids are essential for machining operations such as turning, milling, drilling, and grinding. These fluids help in reducing tool wear, improving surface finish, and increasing the overall efficiency of the machining process. By using biodegradable and non-toxic fluids, mechanical workshops can significantly reduce their environmental footprint and ensure a safer working environment for their employees. In the automobile industry, the demand for eco-friendly cutting fluids is driven by the need for precision and efficiency in manufacturing components such as engine parts, transmission systems, and body panels. These fluids play a crucial role in maintaining the quality and performance of automotive parts while adhering to stringent environmental regulations. The use of sustainable cutting fluids also aligns with the industry's shift towards greener manufacturing practices and the development of eco-friendly vehicles. In the 3C electronic industry, which includes computers, communications, and consumer electronics, eco-friendly cutting fluids are used in the production of components such as circuit boards, connectors, and casings. The precision required in electronic manufacturing necessitates the use of high-performance cutting fluids that can provide excellent cooling and lubrication without compromising the integrity of delicate components. The adoption of eco-friendly fluids in this sector not only supports environmental sustainability but also enhances the quality and reliability of electronic products. Other industries, such as aerospace, medical devices, and energy, also benefit from the use of eco-friendly cutting fluids. In aerospace, these fluids are used in the machining of high-strength alloys and composites, where precision and performance are critical. In the medical device industry, the use of non-toxic and biocompatible cutting fluids is essential to ensure the safety and quality of medical components. The energy sector, particularly in the manufacturing of wind turbines and solar panels, also relies on eco-friendly cutting fluids to enhance the efficiency and sustainability of their production processes. Overall, the adoption of eco-friendly cutting fluids across various industries is driven by the need to balance performance, cost-effectiveness, and environmental responsibility. As industries continue to evolve and prioritize sustainability, the demand for these green solutions is expected to grow, leading to further innovations and advancements in the market.

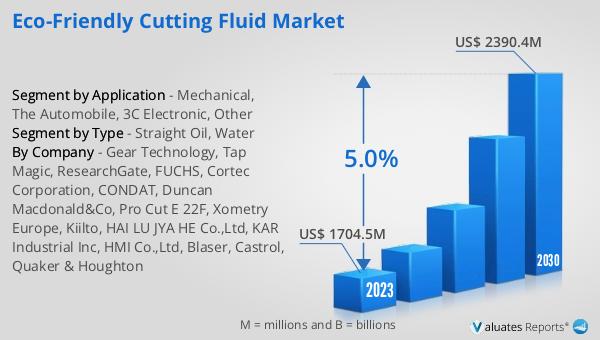

Global Eco-Friendly Cutting Fluid Market Outlook:

The global market for eco-friendly cutting fluids is experiencing a notable upward trajectory. In 2024, the market was valued at approximately $1,869 million. This figure is projected to increase significantly, reaching an estimated $2,608 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.0% over the forecast period. This steady increase underscores the growing importance and adoption of sustainable practices in industrial operations worldwide. The shift towards eco-friendly cutting fluids is driven by several factors, including stringent environmental regulations, increasing awareness about the benefits of sustainable manufacturing, and the rising demand for safer workplace environments. Companies are increasingly recognizing the long-term benefits of adopting eco-friendly solutions, not only in terms of environmental impact but also in enhancing operational efficiency and reducing costs. The market's growth is further supported by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of eco-friendly cutting fluids. As industries continue to prioritize sustainability, the demand for these green solutions is expected to rise, leading to further innovations and advancements in the market. This trend reflects a broader movement towards more sustainable and responsible industrial practices, which are essential for addressing global environmental challenges and ensuring a sustainable future.

| Report Metric | Details |

| Report Name | Eco-Friendly Cutting Fluid Market |

| Accounted market size in year | US$ 1869 million |

| Forecasted market size in 2031 | US$ 2608 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gear Technology, Tap Magic, ResearchGate, FUCHS, Cortec Corporation, CONDAT, Duncan Macdonald&Co, Pro Cut E 22F, Xometry Europe, Kiilto, HAI LU JYA HE Co.,Ltd, KAR Industrial Inc, HMI Co.,Ltd, Blaser, Castrol, Quaker & Houghton |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |