What is Global Industrial Machine Vision Market?

The Global Industrial Machine Vision Market is a rapidly evolving sector that focuses on the use of technology to enable machines to "see" and interpret visual data. This market encompasses a wide range of applications and technologies that allow machines to perform tasks that require visual recognition, such as quality inspection, measurement, and identification. Industrial machine vision systems are equipped with cameras and sensors that capture images, which are then processed using advanced algorithms to extract meaningful information. This technology is crucial in industries where precision and accuracy are paramount, such as manufacturing, automotive, and electronics. The market is driven by the increasing demand for automation and the need for efficient quality control processes. As industries continue to adopt smart manufacturing practices, the role of machine vision systems becomes even more significant, offering enhanced productivity, reduced errors, and improved operational efficiency. The global industrial machine vision market is poised for growth as technological advancements continue to expand its capabilities and applications across various sectors.

PC-based, Smart Camera-based in the Global Industrial Machine Vision Market:

In the realm of the Global Industrial Machine Vision Market, two primary types of systems are prevalent: PC-based and Smart Camera-based systems. PC-based machine vision systems are traditional setups that rely on a personal computer to process images captured by cameras. These systems are highly flexible and customizable, making them suitable for complex applications that require high processing power and sophisticated algorithms. They are often used in environments where multiple cameras are needed, and the processing demands are substantial. The advantage of PC-based systems lies in their ability to handle large volumes of data and perform intricate image analysis, which is essential for tasks such as 3D imaging, pattern recognition, and detailed inspections. However, they can be more expensive and require more space and maintenance compared to their counterparts. On the other hand, Smart Camera-based systems integrate the camera and processing unit into a single device, offering a more compact and cost-effective solution. These systems are designed for ease of use and are ideal for applications where space is limited, and the tasks are less complex. Smart cameras are equipped with built-in processors that can perform basic image processing tasks, such as barcode reading, presence detection, and simple inspections. They are particularly popular in industries that require quick deployment and minimal setup, such as packaging, pharmaceuticals, and food and beverage. The simplicity and affordability of smart cameras make them an attractive option for small to medium-sized enterprises looking to implement machine vision technology without significant investment. Both PC-based and Smart Camera-based systems have their unique advantages and are chosen based on the specific needs of the application. While PC-based systems offer greater flexibility and processing power, Smart Camera-based systems provide a more streamlined and cost-effective solution. The choice between the two often depends on factors such as the complexity of the task, budget constraints, and the available space for installation. As technology continues to advance, the capabilities of both types of systems are expected to improve, further expanding their applications and benefits in the industrial machine vision market.

Automotive, Medical, Industrial, Utilities in the Global Industrial Machine Vision Market:

The Global Industrial Machine Vision Market finds extensive usage across various sectors, including automotive, medical, industrial, and utilities. In the automotive industry, machine vision systems are employed for quality control and inspection processes. They are used to ensure that components are manufactured to precise specifications and to detect defects in parts such as engines, transmissions, and body panels. Machine vision technology helps in reducing errors and improving the overall quality of vehicles, leading to increased customer satisfaction and reduced warranty costs. In the medical field, machine vision systems play a crucial role in enhancing the accuracy and efficiency of diagnostic and treatment processes. They are used in applications such as medical imaging, laboratory automation, and surgical guidance. Machine vision technology enables precise measurements and analysis, which are essential for accurate diagnosis and treatment planning. It also helps in automating repetitive tasks, allowing medical professionals to focus on more critical aspects of patient care. In industrial settings, machine vision systems are used for a wide range of applications, including assembly line inspection, robotic guidance, and inventory management. They help in ensuring that products meet quality standards and are free from defects. Machine vision technology also aids in optimizing production processes by providing real-time data and insights, leading to increased efficiency and reduced downtime. In the utilities sector, machine vision systems are used for monitoring and inspection of infrastructure such as pipelines, power lines, and water treatment facilities. They help in detecting faults and anomalies, allowing for timely maintenance and repairs. Machine vision technology also plays a role in ensuring the safety and reliability of utility services, contributing to improved service delivery and customer satisfaction. Overall, the Global Industrial Machine Vision Market offers significant benefits across various sectors, enhancing quality, efficiency, and safety. As industries continue to embrace automation and smart technologies, the demand for machine vision systems is expected to grow, driving further advancements and innovations in this field.

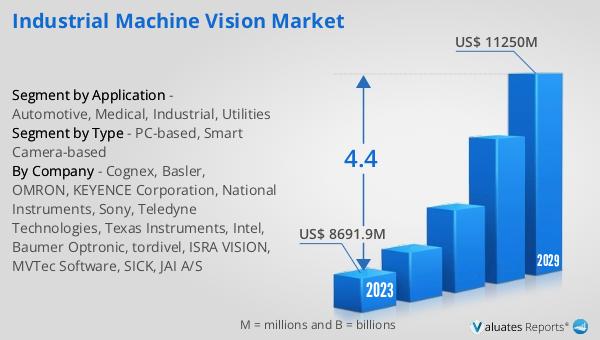

Global Industrial Machine Vision Market Outlook:

The global market for Industrial Machine Vision was valued at $9,036 million in 2024, and it is anticipated to expand to a revised size of $12,160 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.4% over the forecast period. This growth trajectory underscores the increasing adoption of machine vision technologies across various industries. The market's expansion is driven by the rising demand for automation and the need for efficient quality control processes. As industries strive to enhance productivity and reduce operational costs, machine vision systems offer a viable solution by providing accurate and reliable visual data analysis. The integration of advanced technologies such as artificial intelligence and machine learning further enhances the capabilities of machine vision systems, enabling them to perform complex tasks with greater precision. This, in turn, fuels their adoption across sectors such as automotive, electronics, and manufacturing. The projected growth of the global industrial machine vision market highlights the significant role that these systems play in modern industrial processes, offering improved efficiency, reduced errors, and enhanced product quality. As the market continues to evolve, it presents numerous opportunities for innovation and development, paving the way for a more automated and efficient future.

| Report Metric | Details |

| Report Name | Industrial Machine Vision Market |

| Accounted market size in year | US$ 9036 million |

| Forecasted market size in 2031 | US$ 12160 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Cognex, Basler, OMRON, KEYENCE Corporation, National Instruments, Sony, Teledyne Technologies, Texas Instruments, Intel, Baumer Optronic, tordivel, ISRA VISION, MVTec Software, SICK, JAI A/S |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |