What is Global Polyethylene Damp Proof Membranes Market?

The Global Polyethylene Damp Proof Membranes Market is a specialized segment within the construction materials industry, focusing on the production and distribution of polyethylene-based membranes designed to prevent moisture ingress in buildings. These membranes are crucial in construction as they act as a barrier to moisture, protecting structures from dampness that can lead to structural damage and mold growth. Polyethylene, a versatile and durable plastic, is the primary material used in these membranes due to its excellent resistance to moisture and chemicals. The market for these membranes is driven by the increasing demand for durable and efficient waterproofing solutions in both residential and commercial construction projects. As urbanization continues to rise globally, the need for effective moisture control solutions becomes more critical, thereby boosting the demand for polyethylene damp proof membranes. The market is characterized by a variety of products that cater to different construction needs, including varying thicknesses and sizes to suit specific project requirements. Additionally, advancements in manufacturing technologies have led to the development of more efficient and environmentally friendly membranes, further propelling market growth. The global market is competitive, with numerous players offering a wide range of products to meet the diverse needs of the construction industry.

1200 Gauge/300μm, 2000 Gauge/500μm in the Global Polyethylene Damp Proof Membranes Market:

In the Global Polyethylene Damp Proof Membranes Market, products are often categorized by their thickness, measured in microns (μm) or gauge. Two common specifications are the 1200 Gauge/300μm and the 2000 Gauge/500μm membranes. The 1200 Gauge/300μm membrane is a popular choice for many construction projects due to its balance of durability and flexibility. It is typically used in residential and light commercial applications where moderate moisture protection is required. This thickness provides a reliable barrier against dampness, preventing moisture from penetrating floors and walls, which can lead to structural issues and health problems associated with mold and mildew. The 1200 Gauge/300μm membrane is easy to handle and install, making it a cost-effective solution for builders and contractors. On the other hand, the 2000 Gauge/500μm membrane offers a higher level of protection, suitable for more demanding environments such as industrial buildings or areas with high water tables. This thicker membrane provides enhanced resistance to punctures and tears, ensuring long-term performance even under challenging conditions. It is often used in commercial and industrial settings where the risk of moisture ingress is higher, and the consequences of dampness can be more severe. The choice between these two specifications depends on the specific requirements of the construction project, including the level of moisture exposure and the desired lifespan of the membrane. Both types of membranes are designed to meet industry standards for moisture protection, ensuring that they provide effective and reliable performance. The Global Polyethylene Damp Proof Membranes Market continues to evolve, with manufacturers developing new products that offer improved performance and sustainability. Innovations in material science and manufacturing processes have led to the creation of membranes that are not only more effective at preventing moisture ingress but also more environmentally friendly. For example, some manufacturers are now producing membranes using recycled polyethylene, reducing the environmental impact of their products. Additionally, advancements in technology have enabled the production of membranes with enhanced properties, such as increased UV resistance and improved flexibility at low temperatures. These innovations are helping to drive growth in the market, as builders and contractors seek out products that offer superior performance and sustainability. The market is also seeing increased demand for customized solutions, with manufacturers offering membranes in a range of sizes and thicknesses to meet the specific needs of different construction projects. This trend towards customization is being driven by the growing complexity of modern construction projects, which often require tailored solutions to address unique challenges. Overall, the Global Polyethylene Damp Proof Membranes Market is a dynamic and evolving industry, with a wide range of products available to meet the diverse needs of the construction sector. As the demand for effective moisture protection solutions continues to grow, the market is expected to see continued innovation and expansion, with new products and technologies emerging to meet the needs of builders and contractors around the world.

Residential, Commercial Building, Industrial Building in the Global Polyethylene Damp Proof Membranes Market:

The usage of Global Polyethylene Damp Proof Membranes Market products varies across different types of buildings, including residential, commercial, and industrial structures. In residential buildings, these membranes are primarily used to protect homes from moisture ingress, which can lead to structural damage and health issues. They are typically installed beneath concrete floors and within walls to create a barrier that prevents dampness from penetrating the building envelope. This is particularly important in areas with high humidity or where the water table is close to the surface. By preventing moisture ingress, polyethylene damp proof membranes help to maintain a healthy indoor environment, reducing the risk of mold growth and improving the overall comfort of the home. In commercial buildings, the need for effective moisture protection is even more critical, as these structures often house valuable assets and equipment that can be damaged by dampness. Polyethylene damp proof membranes are used in a variety of applications within commercial buildings, including beneath flooring, within walls, and around foundations. They provide a reliable barrier against moisture, ensuring that the building remains dry and free from damp-related issues. This is particularly important in commercial settings where the presence of moisture can lead to costly repairs and disruptions to business operations. In industrial buildings, the use of polyethylene damp proof membranes is essential for protecting the structure and its contents from moisture ingress. These buildings often house sensitive equipment and materials that can be damaged by dampness, making effective moisture protection a top priority. Polyethylene damp proof membranes are used in a variety of applications within industrial buildings, including beneath concrete slabs, within walls, and around foundations. They provide a robust barrier against moisture, ensuring that the building remains dry and free from damp-related issues. This is particularly important in industrial settings where the presence of moisture can lead to costly repairs and disruptions to operations. Overall, the usage of polyethylene damp proof membranes in residential, commercial, and industrial buildings is essential for protecting structures from moisture ingress and ensuring a healthy and comfortable indoor environment. These membranes provide a reliable barrier against dampness, preventing moisture from penetrating the building envelope and causing structural damage and health issues. As the demand for effective moisture protection solutions continues to grow, the Global Polyethylene Damp Proof Membranes Market is expected to see continued innovation and expansion, with new products and technologies emerging to meet the needs of builders and contractors around the world.

Global Polyethylene Damp Proof Membranes Market Outlook:

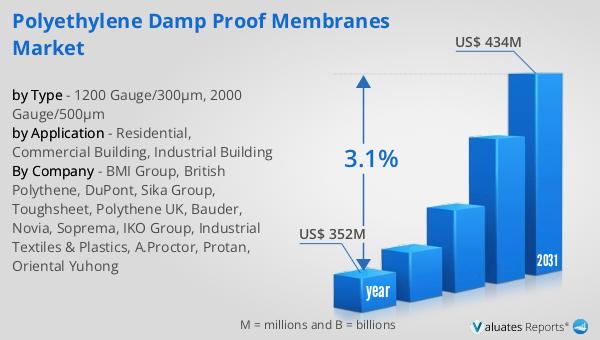

The global market for Polyethylene Damp Proof Membranes was valued at $352 million in 2024, and it is anticipated to grow to a revised size of $434 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% over the forecast period. This growth trajectory underscores the increasing demand for effective moisture protection solutions in the construction industry. As urbanization and infrastructure development continue to accelerate worldwide, the need for durable and efficient damp proofing materials becomes more pronounced. Polyethylene damp proof membranes are favored for their excellent moisture resistance, durability, and cost-effectiveness, making them a preferred choice for builders and contractors. The market's expansion is also driven by advancements in manufacturing technologies, which have led to the development of more efficient and environmentally friendly membranes. These innovations are helping to meet the growing demand for sustainable construction materials, as builders and contractors seek out products that offer superior performance and reduced environmental impact. Additionally, the market is seeing increased demand for customized solutions, with manufacturers offering membranes in a range of sizes and thicknesses to meet the specific needs of different construction projects. This trend towards customization is being driven by the growing complexity of modern construction projects, which often require tailored solutions to address unique challenges. Overall, the Global Polyethylene Damp Proof Membranes Market is poised for continued growth, with new products and technologies emerging to meet the needs of builders and contractors around the world.

| Report Metric | Details |

| Report Name | Polyethylene Damp Proof Membranes Market |

| Accounted market size in year | US$ 352 million |

| Forecasted market size in 2031 | US$ 434 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BMI Group, British Polythene, DuPont, Sika Group, Toughsheet, Polythene UK, Bauder, Novia, Soprema, IKO Group, Industrial Textiles & Plastics, A.Proctor, Protan, Oriental Yuhong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |