What is Global Earthquake Resistant Ductile Iron Pipe Market?

The Global Earthquake Resistant Ductile Iron Pipe Market is a specialized segment within the broader infrastructure and construction industry, focusing on the development and distribution of ductile iron pipes designed to withstand seismic activities. These pipes are engineered to maintain their integrity and functionality during and after earthquakes, making them crucial for regions prone to seismic disturbances. The market encompasses a range of products that vary in size, strength, and application, catering to diverse needs in urban planning, water distribution, and industrial projects. The demand for these pipes is driven by the increasing awareness of the need for resilient infrastructure, especially in earthquake-prone areas. As urbanization continues to expand globally, the need for reliable and durable piping solutions becomes more critical, prompting governments and private sectors to invest in earthquake-resistant technologies. This market not only addresses the immediate safety concerns associated with seismic events but also contributes to the long-term sustainability and efficiency of urban infrastructure systems. The growth of this market is indicative of a broader trend towards enhancing the resilience of essential services and utilities, ensuring that they remain operational even in the face of natural disasters.

DN 80mm-300mm, DN 350mm-1000mm, DN 1100mm-1200mm, DN 1400mm-2000mm, Others in the Global Earthquake Resistant Ductile Iron Pipe Market:

The Global Earthquake Resistant Ductile Iron Pipe Market is segmented based on the diameter of the pipes, which determines their specific applications and suitability for different projects. The DN 80mm-300mm category represents smaller diameter pipes typically used in residential and small-scale commercial applications. These pipes are essential for distributing water and other utilities in urban and suburban areas, where space constraints and the need for flexibility are paramount. The DN 350mm-1000mm range caters to medium-sized projects, including larger commercial developments and municipal infrastructure. These pipes are often employed in water supply networks, where they must balance capacity with the ability to withstand seismic forces. Moving to the DN 1100mm-1200mm category, these pipes are designed for more substantial infrastructure projects, such as major urban water distribution systems and industrial applications. Their larger diameter allows for higher flow rates, making them suitable for areas with significant demand. The DN 1400mm-2000mm pipes are among the largest in this market, used in extensive infrastructure projects like regional water supply systems, large-scale industrial facilities, and critical utility networks. These pipes must not only handle high volumes but also provide exceptional durability and resistance to seismic activity. Finally, the "Others" category includes pipes that fall outside these standard diameters, often customized for specific projects or unique applications. This segmentation allows the market to address a wide range of needs, ensuring that infrastructure can be tailored to the specific seismic risks and requirements of different regions. By offering a variety of sizes, the market ensures that all levels of infrastructure, from small residential systems to large industrial networks, can benefit from the enhanced safety and reliability of earthquake-resistant ductile iron pipes. This comprehensive approach is essential for building resilient communities that can withstand the challenges posed by natural disasters.

Wastewater Treatment, Offshore, Gas and Oil, Mining, Other in the Global Earthquake Resistant Ductile Iron Pipe Market:

The usage of Global Earthquake Resistant Ductile Iron Pipes spans several critical areas, each with unique requirements and challenges. In wastewater treatment, these pipes play a vital role in transporting sewage and treated water. The resilience of ductile iron pipes ensures that wastewater systems remain operational during seismic events, preventing environmental contamination and maintaining public health standards. Offshore applications also benefit significantly from these pipes, as they are used in underwater pipelines that must endure both seismic activity and harsh marine conditions. The durability and flexibility of ductile iron make them ideal for such demanding environments, where failure could lead to catastrophic consequences. In the gas and oil industry, earthquake-resistant ductile iron pipes are crucial for maintaining the integrity of pipelines that transport these valuable resources. Any disruption in these systems can have significant economic and environmental impacts, making the reliability of these pipes essential. Mining operations also rely on these pipes for transporting water, slurry, and other materials. The robust nature of ductile iron pipes ensures that mining operations can continue safely and efficiently, even in seismically active regions. Finally, the "Other" category encompasses a range of applications, from industrial processes to urban infrastructure projects. In all these areas, the primary advantage of using earthquake-resistant ductile iron pipes is their ability to maintain functionality and safety during and after seismic events. This reliability is crucial for minimizing downtime, reducing repair costs, and ensuring the continuous operation of essential services. By investing in these advanced piping solutions, industries and municipalities can enhance their resilience to natural disasters, safeguarding both economic interests and public safety.

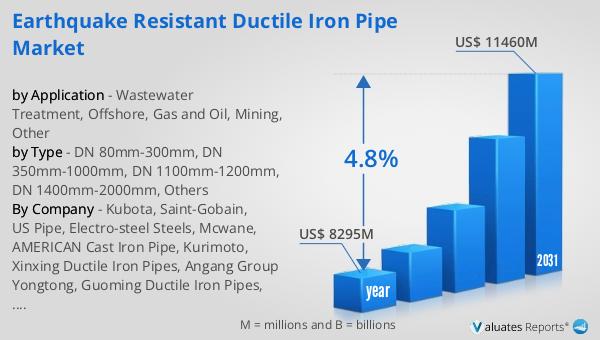

Global Earthquake Resistant Ductile Iron Pipe Market Outlook:

In 2024, the global market for Earthquake Resistant Ductile Iron Pipes was valued at approximately $8,295 million. This market is anticipated to grow significantly, reaching an estimated size of $11,460 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.8% over the forecast period. This upward trend highlights the increasing demand for durable and reliable infrastructure solutions in regions prone to seismic activity. The projected growth is driven by several factors, including the rising awareness of the importance of resilient infrastructure, the expansion of urban areas, and the need for sustainable development practices. As more regions recognize the risks associated with earthquakes, the demand for earthquake-resistant ductile iron pipes is expected to rise, supporting the development of safer and more reliable infrastructure systems. This market outlook underscores the critical role that these pipes play in enhancing the resilience of essential services and utilities, ensuring that they remain operational even in the face of natural disasters. By investing in these advanced piping solutions, industries and municipalities can better protect their infrastructure and communities from the impacts of seismic events.

| Report Metric | Details |

| Report Name | Earthquake Resistant Ductile Iron Pipe Market |

| Accounted market size in year | US$ 8295 million |

| Forecasted market size in 2031 | US$ 11460 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kubota, Saint-Gobain, US Pipe, Electro-steel Steels, Mcwane, AMERICAN Cast Iron Pipe, Kurimoto, Xinxing Ductile Iron Pipes, Angang Group Yongtong, Guoming Ductile Iron Pipes, Jindal SAW, Tubos |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |