What is Global Precision Micro Stamping Market?

The Global Precision Micro Stamping Market is a specialized segment of the manufacturing industry that focuses on the production of small, intricate metal components through a process known as micro stamping. This market is characterized by its ability to produce high-precision parts that are essential in various high-tech industries. Micro stamping involves the use of advanced machinery and techniques to create components with tight tolerances and complex geometries. These components are often used in applications where precision and reliability are critical, such as in medical devices, electronics, and automotive systems. The market is driven by the increasing demand for miniaturized components that can perform complex functions in compact spaces. As technology continues to advance, the need for precision micro stamping is expected to grow, as it enables manufacturers to produce parts that meet the stringent requirements of modern applications. The market is also influenced by factors such as technological advancements, material innovations, and the growing trend towards automation in manufacturing processes. Overall, the Global Precision Micro Stamping Market plays a crucial role in supporting the development and production of cutting-edge technologies across various industries.

Progressive Die Stamping, Deep Drawn Stamping in the Global Precision Micro Stamping Market:

Progressive Die Stamping and Deep Drawn Stamping are two critical processes within the Global Precision Micro Stamping Market, each offering unique advantages and applications. Progressive Die Stamping is a method that involves feeding a strip of metal through a series of stations, each performing a specific operation such as cutting, bending, or punching. This process is highly efficient for producing large volumes of parts with consistent quality and precision. The progressive die is designed to perform multiple operations in a single pass, reducing the need for secondary processes and minimizing material waste. This makes it ideal for applications where high production rates and cost-effectiveness are essential, such as in the automotive and electronics industries. On the other hand, Deep Drawn Stamping is a process used to create parts with significant depth and complex shapes. It involves drawing a flat sheet of metal into a die cavity, forming it into a desired shape through a series of drawing operations. This method is particularly suited for producing components with deep, hollow shapes, such as cans, enclosures, and housings. Deep Drawn Stamping offers advantages in terms of material utilization and structural integrity, as the process allows for the creation of seamless parts with uniform wall thickness. This is especially important in industries like medical devices and consumer electronics, where the strength and durability of components are paramount. Both Progressive Die Stamping and Deep Drawn Stamping are integral to the precision micro stamping market, providing manufacturers with the flexibility to produce a wide range of parts with varying complexities and specifications. As the demand for miniaturized and high-performance components continues to rise, these stamping processes are expected to play an increasingly important role in meeting the needs of modern manufacturing. The choice between Progressive Die Stamping and Deep Drawn Stamping often depends on the specific requirements of the application, including factors such as part geometry, material properties, and production volume. Manufacturers must carefully consider these factors to select the most appropriate stamping process for their needs, ensuring that they can deliver high-quality components that meet the stringent demands of today's technology-driven markets. Overall, the integration of these advanced stamping techniques within the Global Precision Micro Stamping Market underscores the industry's commitment to innovation and excellence in manufacturing.

Industrial Equipment, Electronics & Semiconductors, Medical Devices, Automotive, Others in the Global Precision Micro Stamping Market:

The Global Precision Micro Stamping Market finds extensive usage across various sectors, including Industrial Equipment, Electronics & Semiconductors, Medical Devices, Automotive, and others. In the realm of Industrial Equipment, precision micro stamping is crucial for producing components that require high durability and precision, such as gears, fasteners, and connectors. These components are essential for the efficient operation of machinery and equipment, ensuring reliability and performance in demanding industrial environments. In the Electronics & Semiconductors sector, micro stamping is employed to manufacture intricate parts like connectors, contacts, and shielding components. The miniaturization trend in electronics has increased the demand for smaller, more efficient components, making precision micro stamping an indispensable process in this industry. The ability to produce parts with tight tolerances and complex geometries is vital for the development of advanced electronic devices and semiconductor technologies. In the Medical Devices industry, precision micro stamping is used to create components for surgical instruments, diagnostic equipment, and implantable devices. The high precision and reliability of stamped parts are critical in medical applications, where the safety and efficacy of devices are paramount. The automotive sector also benefits significantly from precision micro stamping, as it enables the production of lightweight, high-strength components that contribute to vehicle performance and fuel efficiency. Stamped parts are used in various automotive applications, including engine components, transmission systems, and safety features. Additionally, the Global Precision Micro Stamping Market serves other industries such as aerospace, telecommunications, and consumer electronics, where the demand for high-quality, precision-engineered components continues to grow. The versatility and efficiency of micro stamping make it a preferred choice for manufacturers seeking to produce complex parts with high accuracy and consistency. As industries continue to evolve and embrace new technologies, the role of precision micro stamping in supporting innovation and development across various sectors is expected to expand, driving further growth and advancements in the market.

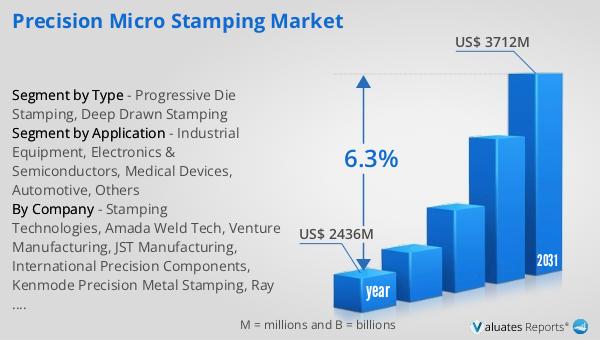

Global Precision Micro Stamping Market Outlook:

The global market for Precision Micro Stamping was valued at $2,436 million in 2024, with projections indicating a growth to $3,712 million by 2031. This represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. This growth trajectory underscores the increasing demand for precision-engineered components across various industries. The market's expansion is driven by the rising need for miniaturized parts that can meet the stringent requirements of modern applications. As industries such as electronics, automotive, and medical devices continue to advance, the demand for high-precision components is expected to rise, fueling the growth of the precision micro stamping market. The market's growth is also supported by technological advancements and innovations in stamping processes, which enhance the efficiency and capabilities of manufacturers. As a result, the precision micro stamping market is poised to play a pivotal role in supporting the development and production of cutting-edge technologies across various sectors. The projected growth of the market reflects the increasing importance of precision micro stamping in meeting the evolving needs of industries worldwide, highlighting its significance as a key driver of innovation and progress in the manufacturing landscape.

| Report Metric | Details |

| Report Name | Precision Micro Stamping Market |

| Accounted market size in year | US$ 2436 million |

| Forecasted market size in 2031 | US$ 3712 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stamping Technologies, Amada Weld Tech, Venture Manufacturing, JST Manufacturing, International Precision Components, Kenmode Precision Metal Stamping, Ray Fuentes Stamping, T.J. Snow Company, Exact Stamping, Advanced Stamping, Apex Stampings, ATS Automation Tooling Systems, YALAN Precision Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |