What is Global Molecular Sieve for Oxygen Generator Market?

The Global Molecular Sieve for Oxygen Generator Market is a specialized segment within the broader industrial and medical gas industry. Molecular sieves are materials with tiny, uniform pores that can selectively adsorb gases and liquids based on molecular size and shape. In the context of oxygen generators, these sieves are crucial for separating oxygen from other gases in the air, such as nitrogen. This separation process is vital for producing high-purity oxygen, which is essential for various applications, including medical, industrial, and environmental. The market for molecular sieves in oxygen generators is driven by the increasing demand for oxygen in healthcare facilities, especially in regions with limited access to centralized oxygen supply systems. Additionally, the industrial sector's need for efficient and cost-effective oxygen production solutions further propels market growth. The market is characterized by technological advancements, with manufacturers focusing on enhancing the efficiency and lifespan of molecular sieves to meet the growing demand. As industries and healthcare systems continue to evolve, the Global Molecular Sieve for Oxygen Generator Market is expected to play a pivotal role in ensuring a reliable supply of oxygen across different sectors.

3A, 4A, 5A, 13X in the Global Molecular Sieve for Oxygen Generator Market:

In the Global Molecular Sieve for Oxygen Generator Market, different types of molecular sieves are utilized, each with unique properties and applications. The most common types are 3A, 4A, 5A, and 13X, each distinguished by their pore sizes and adsorption characteristics. The 3A molecular sieve, with a pore size of approximately 3 angstroms, is primarily used for drying gases and liquids. Its ability to selectively adsorb molecules smaller than its pore size makes it ideal for removing moisture from air streams, which is crucial in oxygen generation to prevent corrosion and ensure the longevity of equipment. The 4A molecular sieve, with a slightly larger pore size of 4 angstroms, is versatile and widely used for both drying and purifying gases. It can adsorb water, carbon dioxide, and other impurities, making it suitable for producing high-purity oxygen. The 5A molecular sieve, with a 5 angstrom pore size, is particularly effective in separating normal paraffins from branched-chain and cyclic hydrocarbons. This property is leveraged in oxygen generators to enhance the purity of the oxygen produced by removing unwanted hydrocarbons. Lastly, the 13X molecular sieve, with the largest pore size among the four, is highly efficient in adsorbing larger molecules, such as carbon dioxide and hydrogen sulfide. Its high adsorption capacity and selectivity make it a preferred choice for applications requiring the removal of a wide range of impurities. In the context of oxygen generators, the 13X sieve is often used in combination with other sieves to achieve optimal performance. The choice of molecular sieve depends on the specific requirements of the oxygen generation process, including the desired purity level, operating conditions, and the presence of specific impurities in the feed gas. Manufacturers in the Global Molecular Sieve for Oxygen Generator Market continuously innovate to improve the performance and durability of these sieves, ensuring they meet the evolving needs of various industries. As the demand for efficient and reliable oxygen generation solutions grows, the role of molecular sieves in enhancing the quality and efficiency of these systems becomes increasingly important.

Medical Oxygen Generator, Industrial Oxygen Generator in the Global Molecular Sieve for Oxygen Generator Market:

The Global Molecular Sieve for Oxygen Generator Market finds significant applications in both medical and industrial oxygen generation. In the medical field, oxygen generators equipped with molecular sieves are essential for providing a continuous supply of high-purity oxygen to patients. These generators are particularly crucial in hospitals, clinics, and emergency medical services, where a reliable oxygen supply can be life-saving. Molecular sieves in medical oxygen generators work by selectively adsorbing nitrogen and other impurities from the air, allowing only oxygen to pass through. This process ensures that the oxygen delivered to patients is of the highest purity, which is vital for effective treatment and recovery. The use of molecular sieves in medical oxygen generators also offers the advantage of on-site oxygen production, reducing the dependency on external oxygen supply chains and ensuring availability even in remote or resource-limited settings. In the industrial sector, oxygen generators with molecular sieves are used in various applications, including metal fabrication, chemical processing, and wastewater treatment. In metal fabrication, high-purity oxygen is used to enhance combustion processes, improve cutting and welding efficiency, and reduce emissions. Molecular sieves in industrial oxygen generators help achieve the required oxygen purity levels by removing contaminants such as moisture, carbon dioxide, and hydrocarbons. In chemical processing, oxygen is used as a reactant in various chemical reactions, and the presence of impurities can affect the quality and yield of the final product. Molecular sieves ensure that the oxygen used is free from contaminants, thereby improving process efficiency and product quality. In wastewater treatment, oxygen is used to support aerobic biological processes that break down organic matter. The use of molecular sieves in oxygen generators ensures a consistent supply of high-purity oxygen, enhancing the efficiency of these processes and reducing environmental impact. Overall, the Global Molecular Sieve for Oxygen Generator Market plays a critical role in ensuring the availability of high-purity oxygen for both medical and industrial applications, contributing to improved healthcare outcomes and industrial efficiency.

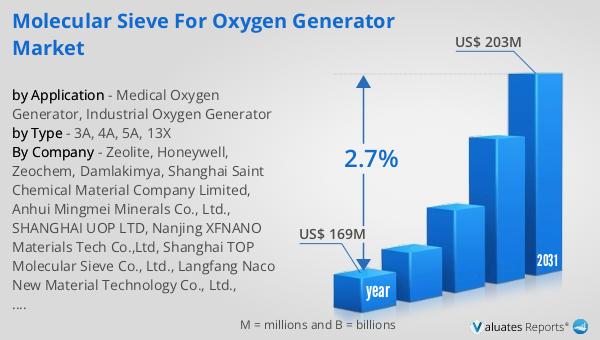

Global Molecular Sieve for Oxygen Generator Market Outlook:

The global market for molecular sieves used in oxygen generators was valued at approximately $169 million in 2024. This market is anticipated to expand, reaching an estimated value of $203 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 2.7% over the forecast period. The steady growth in this market can be attributed to the increasing demand for efficient oxygen generation solutions across various sectors. In the medical field, the need for reliable and high-purity oxygen supply systems is a significant driver, especially in regions with limited access to centralized oxygen infrastructure. The industrial sector also contributes to market growth, with industries seeking cost-effective and efficient oxygen production methods to enhance operational efficiency and product quality. The market's expansion is further supported by technological advancements in molecular sieve materials, which enhance the performance and lifespan of oxygen generators. As the demand for oxygen continues to rise, driven by factors such as population growth, urbanization, and industrialization, the Global Molecular Sieve for Oxygen Generator Market is poised for sustained growth. This market outlook highlights the critical role of molecular sieves in meeting the evolving needs of various industries and healthcare systems, ensuring a reliable supply of high-purity oxygen.

| Report Metric | Details |

| Report Name | Molecular Sieve for Oxygen Generator Market |

| Accounted market size in year | US$ 169 million |

| Forecasted market size in 2031 | US$ 203 million |

| CAGR | 2.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zeolite, Honeywell, Zeochem, Damlakimya, Shanghai Saint Chemical Material Company Limited, Anhui Mingmei Minerals Co., Ltd., SHANGHAI UOP LTD, Nanjing XFNANO Materials Tech Co.,Ltd, Shanghai TOP Molecular Sieve Co., Ltd., Langfang Naco New Material Technology Co., Ltd., Luoyang Jalon Micro-nano New Materials Co.,ltd., Naike Chemical Equipment Packing Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |