What is Global Flexible Expanded Graphite Foil Market?

The Global Flexible Expanded Graphite Foil Market is a specialized segment within the broader graphite industry, focusing on the production and application of flexible graphite foils. These foils are made from expanded graphite, a material known for its excellent thermal and electrical conductivity, flexibility, and chemical resistance. The process of creating expanded graphite involves treating natural graphite flakes with acid and heat, causing them to expand and form a lightweight, flexible material. This expanded graphite is then compressed into thin sheets or foils, which can be used in a variety of applications. The market for these foils is driven by their versatility and performance in demanding environments, making them ideal for use in industries such as electronics, automotive, chemical processing, and energy. As industries continue to seek materials that offer high performance and sustainability, the demand for flexible expanded graphite foils is expected to grow. These foils are particularly valued for their ability to withstand extreme temperatures and corrosive environments, making them a critical component in many industrial applications. The market is characterized by ongoing innovation and development, as manufacturers strive to enhance the properties and applications of these versatile materials.

Carbon Content: 98%-99%, Carbon Content: >99% in the Global Flexible Expanded Graphite Foil Market:

In the Global Flexible Expanded Graphite Foil Market, carbon content is a critical factor that influences the performance and application of the foils. The carbon content of these foils typically falls into two categories: 98%-99% and greater than 99%. Each category offers distinct properties and advantages, catering to different industrial needs. Foils with a carbon content of 98%-99% are known for their excellent balance of performance and cost-effectiveness. They provide good thermal and electrical conductivity, making them suitable for a wide range of applications, including gaskets, seals, and heat shields. These foils are often used in industries where moderate performance is required, and cost considerations are important. On the other hand, foils with a carbon content greater than 99% offer superior performance characteristics. The higher carbon content enhances the thermal and electrical conductivity of the foils, making them ideal for high-performance applications. These foils are often used in industries that demand the highest levels of performance, such as aerospace, electronics, and high-temperature processing. The increased purity of these foils also contributes to their chemical resistance, making them suitable for use in harsh environments. The choice between these two categories of carbon content depends on the specific requirements of the application. Industries that require high thermal and electrical conductivity, as well as chemical resistance, may opt for foils with a carbon content greater than 99%. Conversely, industries that prioritize cost-effectiveness and moderate performance may choose foils with a carbon content of 98%-99%. The market for flexible expanded graphite foils is driven by the diverse needs of various industries, and manufacturers continue to innovate to meet these demands. Advances in production technology and material science are enabling the development of foils with enhanced properties, further expanding their range of applications. As industries continue to evolve and seek materials that offer both performance and sustainability, the demand for flexible expanded graphite foils with varying carbon content is expected to grow. The market is characterized by a focus on quality, performance, and innovation, as manufacturers strive to meet the changing needs of their customers. The choice of carbon content in flexible expanded graphite foils is a critical consideration for industries seeking to optimize performance and cost-effectiveness. By understanding the unique properties and advantages of each category, industries can make informed decisions that align with their specific requirements and goals.

Chemical, Oil and Gas, Other in the Global Flexible Expanded Graphite Foil Market:

The Global Flexible Expanded Graphite Foil Market finds extensive usage across various industries, including chemical, oil and gas, and others, due to its unique properties and versatility. In the chemical industry, flexible expanded graphite foils are highly valued for their chemical resistance and ability to withstand extreme temperatures. These foils are commonly used in the production of gaskets and seals, which are essential components in chemical processing equipment. The foils' ability to maintain integrity in corrosive environments makes them ideal for use in reactors, heat exchangers, and other critical equipment. Additionally, their flexibility allows for easy installation and maintenance, reducing downtime and improving operational efficiency. In the oil and gas industry, flexible expanded graphite foils play a crucial role in ensuring the safety and efficiency of operations. The foils are used in the production of seals and gaskets for pipelines, valves, and other equipment, where they provide reliable sealing performance under high pressure and temperature conditions. Their resistance to chemicals and extreme temperatures makes them suitable for use in harsh environments, such as offshore drilling platforms and refineries. The foils' ability to prevent leaks and ensure the integrity of equipment is critical for maintaining safety and minimizing environmental impact. Beyond the chemical and oil and gas industries, flexible expanded graphite foils are used in a variety of other applications. In the automotive industry, they are used in the production of heat shields and gaskets, where their thermal conductivity and flexibility provide effective heat management and sealing solutions. In the electronics industry, the foils are used in the production of thermal interface materials, which help dissipate heat from electronic components and improve device performance. The versatility of flexible expanded graphite foils makes them suitable for use in a wide range of applications, from industrial to consumer products. The market for these foils is driven by the need for materials that offer high performance, reliability, and sustainability. As industries continue to seek solutions that enhance efficiency and reduce environmental impact, the demand for flexible expanded graphite foils is expected to grow. Manufacturers are continually innovating to develop foils with enhanced properties, expanding their range of applications and meeting the evolving needs of their customers. The usage of flexible expanded graphite foils in various industries highlights their importance as a versatile and high-performance material. By understanding the unique properties and advantages of these foils, industries can leverage their benefits to improve operational efficiency, safety, and sustainability.

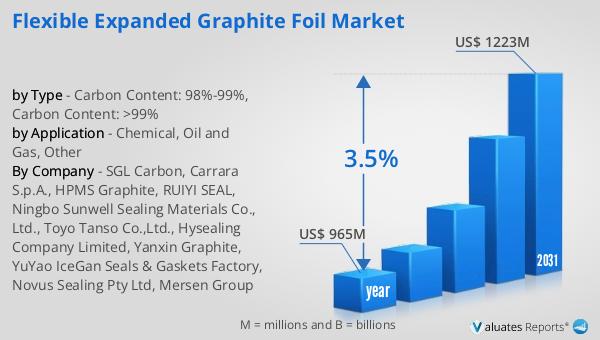

Global Flexible Expanded Graphite Foil Market Outlook:

The global market for Flexible Expanded Graphite Foil was valued at approximately $965 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $1,223 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% over the forecast period. This market expansion reflects the increasing demand for flexible expanded graphite foils across various industries, driven by their unique properties and versatility. The foils' ability to withstand extreme temperatures, resist chemicals, and provide excellent thermal and electrical conductivity makes them a valuable material in industries such as electronics, automotive, chemical processing, and energy. As industries continue to seek materials that offer high performance and sustainability, the demand for flexible expanded graphite foils is expected to grow. The market is characterized by ongoing innovation and development, as manufacturers strive to enhance the properties and applications of these versatile materials. The projected growth of the market underscores the importance of flexible expanded graphite foils as a critical component in many industrial applications. By understanding the market dynamics and trends, stakeholders can make informed decisions and capitalize on the opportunities presented by this growing market.

| Report Metric | Details |

| Report Name | Flexible Expanded Graphite Foil Market |

| Accounted market size in year | US$ 965 million |

| Forecasted market size in 2031 | US$ 1223 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SGL Carbon, Carrara S.p.A., HPMS Graphite, RUIYI SEAL, Ningbo Sunwell Sealing Materials Co., Ltd., Toyo Tanso Co.,Ltd., Hysealing Company Limited, Yanxin Graphite, YuYao IceGan Seals & Gaskets Factory, Novus Sealing Pty Ltd, Mersen Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |