What is Global PU Foam Sealing Material Market?

The Global PU Foam Sealing Material Market is a dynamic and evolving sector that plays a crucial role in various industries worldwide. PU, or polyurethane, foam sealing materials are versatile products used for sealing, insulating, and protecting different surfaces and components. These materials are known for their excellent thermal insulation properties, flexibility, and durability, making them ideal for a wide range of applications. The market for PU foam sealing materials is driven by the increasing demand for energy-efficient solutions and the growing construction and automotive industries. As these industries expand, the need for effective sealing solutions to enhance energy efficiency and reduce environmental impact becomes more critical. Additionally, the electronics industry also contributes to the demand for PU foam sealing materials, as they are used to protect sensitive components from moisture and dust. The market is characterized by continuous innovation, with manufacturers focusing on developing eco-friendly and high-performance products to meet the evolving needs of consumers and industries. Overall, the Global PU Foam Sealing Material Market is poised for growth, driven by technological advancements and the increasing emphasis on sustainability across various sectors.

Open-cell, Closed-cell in the Global PU Foam Sealing Material Market:

Open-cell and closed-cell polyurethane (PU) foam sealing materials are two primary types of foams used in various applications, each with distinct characteristics and benefits. Open-cell PU foam is characterized by its interconnected cell structure, which allows air and moisture to pass through. This type of foam is softer and more flexible, making it ideal for applications where cushioning and sound absorption are essential. Open-cell foam is commonly used in applications such as furniture cushioning, soundproofing, and packaging. Its ability to absorb sound makes it a popular choice in environments where noise reduction is crucial, such as recording studios and office spaces. Additionally, open-cell foam is often used in automotive interiors to provide comfort and reduce noise levels. On the other hand, closed-cell PU foam has a denser structure with cells that are completely enclosed, preventing air and moisture from passing through. This makes closed-cell foam more rigid and durable, providing excellent thermal insulation and water resistance. Closed-cell foam is commonly used in applications where moisture resistance and structural integrity are critical, such as in building insulation, roofing, and marine environments. Its high compressive strength and resistance to water make it suitable for use in harsh environments where durability is essential. In the automotive industry, closed-cell foam is used for sealing and insulating components to enhance vehicle performance and efficiency. The choice between open-cell and closed-cell PU foam sealing materials depends on the specific requirements of the application. For instance, in the construction industry, closed-cell foam is often preferred for insulation purposes due to its superior thermal resistance and moisture barrier properties. It helps in reducing energy consumption by maintaining consistent indoor temperatures and preventing heat loss. In contrast, open-cell foam is favored for soundproofing applications due to its ability to absorb sound waves and reduce noise levels. In the electronics industry, both open-cell and closed-cell foams are used for different purposes. Open-cell foam is used for cushioning and protecting delicate electronic components during transportation and handling. Its flexibility and shock-absorbing properties help prevent damage to sensitive parts. Closed-cell foam, on the other hand, is used for sealing and insulating electronic enclosures to protect against moisture, dust, and other environmental factors. Overall, the Global PU Foam Sealing Material Market offers a wide range of options for various industries, each with its unique set of benefits and applications. The choice between open-cell and closed-cell foam depends on factors such as the desired level of insulation, moisture resistance, and structural integrity. As industries continue to evolve and demand more efficient and sustainable solutions, the market for PU foam sealing materials is expected to grow, driven by innovation and the development of new products that meet the changing needs of consumers and industries.

Automotive, Building, Electronics, Other in the Global PU Foam Sealing Material Market:

The Global PU Foam Sealing Material Market finds extensive usage across various sectors, including automotive, building, electronics, and others, due to its versatile properties and benefits. In the automotive industry, PU foam sealing materials are used for a variety of applications, including sealing, insulation, and cushioning. They help improve vehicle performance by reducing noise, vibration, and harshness (NVH) levels, enhancing passenger comfort. PU foam is also used in automotive interiors for seat cushioning, headrests, and armrests, providing comfort and support to passengers. Additionally, PU foam sealing materials are used in engine compartments and underbody components to provide thermal insulation and protect against moisture and dust. In the building and construction industry, PU foam sealing materials are widely used for insulation and sealing purposes. They help improve energy efficiency by reducing heat loss and maintaining consistent indoor temperatures. PU foam is used in walls, roofs, and floors to provide thermal insulation and prevent air leakage. It is also used for sealing gaps and joints in buildings to prevent moisture infiltration and enhance structural integrity. The use of PU foam sealing materials in construction helps reduce energy consumption and lower heating and cooling costs, making buildings more sustainable and environmentally friendly. In the electronics industry, PU foam sealing materials are used for protecting sensitive components from environmental factors such as moisture, dust, and temperature fluctuations. They are used in electronic enclosures, connectors, and circuit boards to provide insulation and prevent damage to delicate components. PU foam is also used for cushioning and protecting electronic devices during transportation and handling, ensuring that they reach their destination without damage. Apart from these industries, PU foam sealing materials are also used in other sectors such as packaging, healthcare, and consumer goods. In the packaging industry, PU foam is used for cushioning and protecting fragile items during shipping and handling. In the healthcare sector, PU foam is used for medical mattresses, cushions, and prosthetics due to its comfort and support properties. In consumer goods, PU foam is used in products such as mattresses, pillows, and furniture for its comfort and durability. Overall, the Global PU Foam Sealing Material Market plays a crucial role in various industries, providing solutions that enhance performance, efficiency, and sustainability. The versatility and adaptability of PU foam sealing materials make them an essential component in a wide range of applications, driving their demand across different sectors.

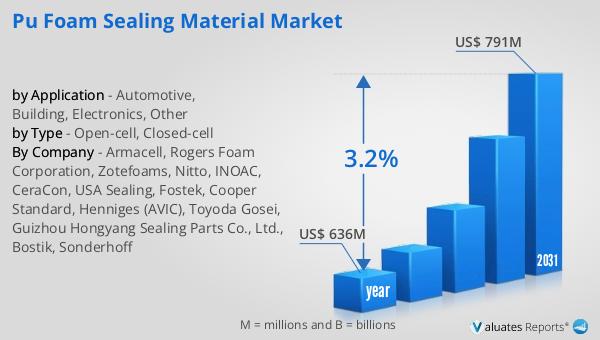

Global PU Foam Sealing Material Market Outlook:

The global market for PU Foam Sealing Material was valued at approximately $636 million in 2024, and it is anticipated to grow to a revised size of around $791 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.2% over the forecast period. This steady growth can be attributed to several factors, including the increasing demand for energy-efficient solutions and the expansion of key industries such as construction, automotive, and electronics. As these industries continue to grow, the need for effective sealing materials that enhance energy efficiency and reduce environmental impact becomes more pronounced. Additionally, the market is driven by technological advancements and innovations in PU foam sealing materials, which offer improved performance and sustainability. Manufacturers are focusing on developing eco-friendly and high-performance products to meet the evolving needs of consumers and industries. The market's growth is also supported by the rising awareness of the benefits of PU foam sealing materials, such as their excellent thermal insulation properties, flexibility, and durability. As a result, the Global PU Foam Sealing Material Market is expected to continue its upward trajectory, driven by the increasing emphasis on sustainability and energy efficiency across various sectors.

| Report Metric | Details |

| Report Name | PU Foam Sealing Material Market |

| Accounted market size in year | US$ 636 million |

| Forecasted market size in 2031 | US$ 791 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Armacell, Rogers Foam Corporation, Zotefoams, Nitto, INOAC, CeraCon, USA Sealing, Fostek, Cooper Standard, Henniges (AVIC), Toyoda Gosei, Guizhou Hongyang Sealing Parts Co., Ltd., Bostik, Sonderhoff |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |