What is Global Heat Preservation Concrete Pipe Market?

The Global Heat Preservation Concrete Pipe Market is a specialized segment within the construction and infrastructure industry, focusing on pipes designed to maintain temperature stability. These pipes are crucial in regions with extreme weather conditions, as they help in conserving energy by minimizing heat loss. The market for these pipes is driven by the increasing demand for efficient thermal management solutions in various sectors, including municipal, industrial, and agricultural applications. Heat preservation concrete pipes are engineered to withstand harsh environmental conditions, ensuring durability and longevity. They are typically used in systems where maintaining a consistent temperature is essential, such as in heating and cooling networks. The market is characterized by technological advancements aimed at improving the insulation properties of these pipes, making them more effective and energy-efficient. As urbanization and industrialization continue to rise globally, the demand for heat preservation concrete pipes is expected to grow, driven by the need for sustainable and energy-efficient infrastructure solutions. This market is also influenced by regulatory standards and environmental policies that promote energy conservation and the use of eco-friendly materials. Overall, the Global Heat Preservation Concrete Pipe Market plays a vital role in supporting infrastructure development while contributing to energy efficiency and sustainability goals.

Direct Burial Heat Preservation Pipe, Overhead Heat Preservation Pipe in the Global Heat Preservation Concrete Pipe Market:

Direct Burial Heat Preservation Pipes and Overhead Heat Preservation Pipes are two primary types of pipes within the Global Heat Preservation Concrete Pipe Market, each serving distinct purposes and applications. Direct Burial Heat Preservation Pipes are designed to be installed underground, providing thermal insulation for various fluid transport systems. These pipes are particularly useful in cold climates where maintaining the temperature of the transported fluid is critical to prevent freezing and ensure efficient flow. The insulation layer in these pipes is typically made from materials like polyurethane foam, which offers excellent thermal resistance. The outer layer is usually made of concrete, providing structural integrity and protection against external pressures and environmental factors. Direct burial pipes are commonly used in district heating systems, where hot water or steam is transported over long distances to provide heating to residential and commercial buildings. They are also used in industrial applications where maintaining process temperatures is crucial. On the other hand, Overhead Heat Preservation Pipes are installed above ground and are often used in situations where underground installation is not feasible or cost-effective. These pipes are designed to withstand exposure to the elements, including UV radiation, temperature fluctuations, and physical impacts. The insulation in overhead pipes is similar to that of direct burial pipes, focusing on minimizing heat loss and maintaining the temperature of the transported fluid. Overhead pipes are often used in industrial settings, such as refineries and chemical plants, where they transport steam, hot water, or other heated fluids across the facility. They are also used in agricultural applications, where they can transport heated water for irrigation systems, ensuring that crops receive water at optimal temperatures for growth. Both types of heat preservation pipes are essential for energy conservation and efficiency in various applications. They help reduce energy consumption by minimizing heat loss, which in turn lowers operational costs and reduces the environmental impact of heating systems. The choice between direct burial and overhead pipes depends on several factors, including the specific application, environmental conditions, and cost considerations. In some cases, a combination of both types may be used to optimize the thermal management of a system. Technological advancements in materials and manufacturing processes have led to improvements in the performance and durability of heat preservation pipes. Innovations such as advanced insulation materials, corrosion-resistant coatings, and enhanced joint designs have contributed to the increased efficiency and lifespan of these pipes. As a result, they are becoming an increasingly popular choice for infrastructure projects that prioritize energy efficiency and sustainability. The Global Heat Preservation Concrete Pipe Market is also influenced by regulatory standards and environmental policies that encourage the use of energy-efficient and environmentally friendly materials. Governments and organizations worldwide are implementing measures to reduce carbon emissions and promote sustainable development, which in turn drives the demand for heat preservation pipes. These pipes play a crucial role in achieving energy conservation goals by reducing the amount of energy required to maintain desired temperatures in various systems. In conclusion, Direct Burial Heat Preservation Pipes and Overhead Heat Preservation Pipes are integral components of the Global Heat Preservation Concrete Pipe Market. They offer effective solutions for maintaining temperature stability in various applications, contributing to energy efficiency and sustainability. As the demand for energy-efficient infrastructure continues to grow, these pipes will play an increasingly important role in supporting sustainable development and reducing the environmental impact of heating systems.

Municipal Engineering, Industrial, Agricultural Irrigation System in the Global Heat Preservation Concrete Pipe Market:

The usage of Global Heat Preservation Concrete Pipes spans across several key areas, including municipal engineering, industrial applications, and agricultural irrigation systems. In municipal engineering, these pipes are primarily used in district heating and cooling systems. District heating systems involve the centralized production of heat, which is then distributed to residential and commercial buildings through a network of insulated pipes. Heat preservation concrete pipes are essential in these systems as they minimize heat loss during transmission, ensuring that the heat reaches its destination efficiently. This not only improves energy efficiency but also reduces the overall cost of heating for municipalities. Additionally, these pipes are used in municipal water supply systems, where maintaining the temperature of the water is crucial to prevent freezing in colder climates. In industrial applications, heat preservation concrete pipes are used in various processes that require the transportation of heated fluids. Industries such as oil and gas, chemical manufacturing, and power generation rely on these pipes to maintain process temperatures and ensure the efficient operation of equipment. For example, in the oil and gas industry, these pipes are used to transport steam and hot water for enhanced oil recovery processes. In chemical manufacturing, they are used to transport heated chemicals and maintain reaction temperatures. The use of heat preservation pipes in these industries helps reduce energy consumption, lower operational costs, and improve the overall efficiency of industrial processes. Agricultural irrigation systems also benefit from the use of heat preservation concrete pipes. In regions with cold climates, maintaining the temperature of irrigation water is essential to prevent freezing and ensure the efficient delivery of water to crops. Heat preservation pipes help achieve this by minimizing heat loss during the transportation of water from the source to the fields. This ensures that crops receive water at optimal temperatures, promoting healthy growth and improving agricultural productivity. Additionally, these pipes can be used in greenhouse heating systems, where maintaining a consistent temperature is crucial for the growth of plants. The use of heat preservation concrete pipes in these areas is driven by the need for energy efficiency and sustainability. By minimizing heat loss and maintaining temperature stability, these pipes help reduce energy consumption and lower greenhouse gas emissions. This aligns with global efforts to promote sustainable development and reduce the environmental impact of infrastructure projects. Furthermore, the durability and longevity of these pipes make them a cost-effective solution for long-term infrastructure needs. In summary, the Global Heat Preservation Concrete Pipe Market plays a vital role in supporting various applications across municipal engineering, industrial processes, and agricultural irrigation systems. These pipes provide effective solutions for maintaining temperature stability, improving energy efficiency, and promoting sustainability. As the demand for energy-efficient infrastructure continues to grow, the use of heat preservation concrete pipes is expected to increase, contributing to the development of sustainable and resilient infrastructure systems.

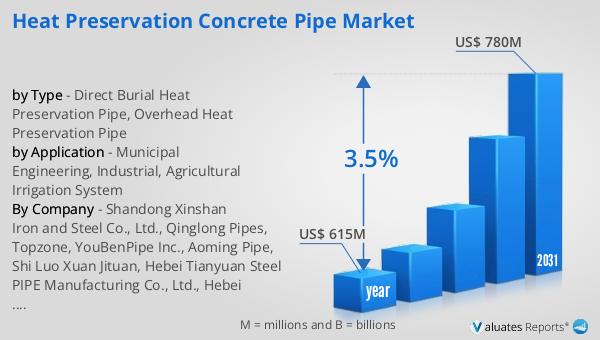

Global Heat Preservation Concrete Pipe Market Outlook:

The global market for Heat Preservation Concrete Pipes was valued at approximately $615 million in 2024. This market is anticipated to expand, reaching an estimated size of $780 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% over the forecast period. The steady increase in market size reflects the rising demand for energy-efficient and sustainable infrastructure solutions across various sectors. As urbanization and industrialization continue to progress globally, the need for effective thermal management systems becomes increasingly important. Heat preservation concrete pipes offer a reliable solution for minimizing heat loss and maintaining temperature stability in various applications, contributing to energy conservation and cost savings. The market's growth is also influenced by technological advancements in materials and manufacturing processes, which enhance the performance and durability of these pipes. Additionally, regulatory standards and environmental policies that promote energy efficiency and the use of eco-friendly materials further drive the demand for heat preservation concrete pipes. As a result, the market is poised for continued expansion, supporting the development of sustainable infrastructure and contributing to global efforts to reduce carbon emissions and promote energy conservation.

| Report Metric | Details |

| Report Name | Heat Preservation Concrete Pipe Market |

| Accounted market size in year | US$ 615 million |

| Forecasted market size in 2031 | US$ 780 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shandong Xinshan Iron and Steel Co., Ltd., Qinglong Pipes, Topzone, YouBenPipe Inc., Aoming Pipe, Shi Luo Xuan Jituan, Hebei Tianyuan Steel PIPE Manufacturing Co., Ltd., Hebei Zhuowei Steel Pipe Manufacturing, Cangzhou Hengtai Pipe Pipe Manufacturing, Hebei Longdu Pipeline Manufacturing Co. Ltd., Hebei Taofa Steel Pipe Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |