What is Global Anti-Static Coating Market?

The Global Anti-Static Coating Market is a specialized segment within the broader coatings industry, focusing on products designed to reduce or eliminate static electricity on surfaces. Static electricity can cause significant issues in various industries, leading to equipment malfunctions, dust attraction, and even potential safety hazards. Anti-static coatings are applied to surfaces to prevent the buildup of static charge, ensuring smooth operation and safety. These coatings are particularly crucial in environments where electronic components are handled, as static discharge can damage sensitive equipment. The market for anti-static coatings is driven by the increasing demand for electronic devices, advancements in technology, and the need for safety in industrial operations. Additionally, the rise in automation and the use of electronic components in various sectors further fuel the demand for these coatings. The market is characterized by a range of products, including ready-to-use coatings and concentrates, catering to different industry needs. As industries continue to prioritize safety and efficiency, the demand for anti-static coatings is expected to grow, making it a vital component in the global coatings market.

Ready-to-Use Anti-Static Coating, Anti-Static Coating Concentrates in the Global Anti-Static Coating Market:

Ready-to-use anti-static coatings and anti-static coating concentrates are two primary product types within the Global Anti-Static Coating Market, each serving distinct purposes and offering unique benefits. Ready-to-use anti-static coatings are pre-formulated solutions that can be directly applied to surfaces without the need for additional preparation or mixing. These coatings are designed for convenience and ease of use, making them ideal for industries that require quick and efficient application processes. They are typically used in environments where immediate static control is necessary, such as in electronic manufacturing facilities, clean rooms, and data centers. The formulation of ready-to-use coatings ensures consistent performance, providing reliable static protection across various surfaces. On the other hand, anti-static coating concentrates are highly concentrated formulations that require dilution before application. These concentrates offer flexibility in terms of customization, allowing users to adjust the concentration based on specific requirements. This adaptability makes them suitable for industries with diverse needs, such as automotive, aerospace, and construction, where different levels of static protection may be required. Concentrates are often preferred by industries that have the capability to handle the mixing process and require large-scale applications. Both ready-to-use coatings and concentrates are formulated using advanced technologies to ensure effective static control. They are designed to be durable, providing long-lasting protection against static buildup. The choice between ready-to-use coatings and concentrates depends on factors such as application requirements, industry standards, and cost considerations. In the automotive industry, for instance, anti-static coatings are used to protect sensitive electronic components from static discharge during manufacturing and assembly processes. Ready-to-use coatings are often preferred for their ease of application and consistent performance, ensuring that electronic systems in vehicles remain protected. In the aerospace sector, where safety and reliability are paramount, anti-static coating concentrates are used to provide customized solutions for different components and surfaces. The ability to adjust the concentration of the coating allows for tailored protection, ensuring that all parts of an aircraft are adequately protected from static-related issues. In the construction industry, anti-static coatings are used to prevent static buildup on surfaces such as floors and walls, reducing the risk of dust attraction and improving safety. Ready-to-use coatings are commonly used in construction projects for their convenience and effectiveness. In electronic product manufacturing, both ready-to-use coatings and concentrates are used to protect sensitive components from static discharge. The choice between the two depends on the specific requirements of the manufacturing process and the level of protection needed. Overall, the Global Anti-Static Coating Market offers a range of products to meet the diverse needs of various industries. Whether it's the convenience of ready-to-use coatings or the flexibility of concentrates, these products play a crucial role in ensuring safety and efficiency in industrial operations. As industries continue to evolve and prioritize static control, the demand for anti-static coatings is expected to grow, driving innovation and development in this specialized market segment.

Automobile, Electronic Product, Aerospace, Construction, Other in the Global Anti-Static Coating Market:

The Global Anti-Static Coating Market finds extensive usage across various industries, including automobile, electronic product manufacturing, aerospace, construction, and others, each with unique requirements and applications. In the automobile industry, anti-static coatings are crucial for protecting sensitive electronic components from static discharge during manufacturing and assembly processes. Modern vehicles are equipped with numerous electronic systems, and any static-related issues can lead to malfunctions or damage. Anti-static coatings ensure that these components remain protected, enhancing the reliability and safety of vehicles. In electronic product manufacturing, anti-static coatings are used to safeguard delicate components from static discharge, which can cause significant damage. The coatings are applied to surfaces such as circuit boards, connectors, and other electronic parts to prevent static buildup. This is particularly important in environments where electronic devices are assembled, as even a small static discharge can render a component unusable. The aerospace industry also relies heavily on anti-static coatings to ensure the safety and reliability of aircraft. Static discharge can pose serious risks in aerospace applications, potentially affecting sensitive avionics and communication systems. Anti-static coatings are applied to various components and surfaces within an aircraft to prevent static buildup and ensure smooth operation. The ability to customize the concentration of anti-static coatings allows for tailored protection, meeting the specific needs of different aerospace applications. In the construction industry, anti-static coatings are used to prevent static buildup on surfaces such as floors and walls. This is particularly important in environments where dust attraction can pose safety hazards or affect the quality of work. Anti-static coatings help maintain a clean and safe working environment, reducing the risk of accidents and improving overall efficiency. Other industries, such as pharmaceuticals, textiles, and packaging, also benefit from the use of anti-static coatings. In pharmaceutical manufacturing, for example, static control is essential to prevent contamination and ensure product quality. Anti-static coatings are applied to equipment and surfaces to minimize static-related issues. In the textile industry, anti-static coatings are used to prevent static cling and improve the handling of fabrics. Packaging industries use anti-static coatings to protect sensitive products during storage and transportation. Overall, the Global Anti-Static Coating Market plays a vital role in ensuring safety, reliability, and efficiency across various industries. The diverse applications of anti-static coatings highlight their importance in modern industrial operations, where static control is a critical consideration. As industries continue to evolve and prioritize safety and efficiency, the demand for anti-static coatings is expected to grow, driving innovation and development in this specialized market segment.

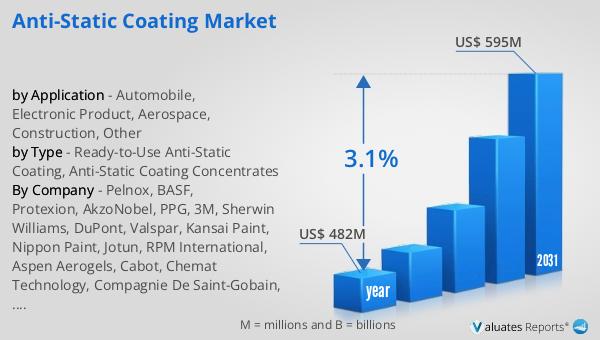

Global Anti-Static Coating Market Outlook:

The global market for anti-static coatings was valued at approximately $482 million in 2024, and it is anticipated to expand to a revised size of around $595 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.1% over the forecast period. The steady increase in market size reflects the rising demand for anti-static coatings across various industries, driven by the need for enhanced safety and efficiency in industrial operations. As industries continue to adopt advanced technologies and prioritize static control, the demand for anti-static coatings is expected to grow, contributing to the overall expansion of the market. The projected growth in the market size underscores the importance of anti-static coatings in modern industrial applications, where static control is a critical consideration. The market's expansion is also indicative of the ongoing innovation and development within the anti-static coatings industry, as manufacturers strive to meet the evolving needs of their customers. As the market continues to grow, it is expected to offer new opportunities for businesses and investors, driving further advancements in anti-static coating technologies and applications.

| Report Metric | Details |

| Report Name | Anti-Static Coating Market |

| Accounted market size in year | US$ 482 million |

| Forecasted market size in 2031 | US$ 595 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Pelnox, BASF, Protexion, AkzoNobel, PPG, 3M, Sherwin Williams, DuPont, Valspar, Kansai Paint, Nippon Paint, Jotun, RPM International, Aspen Aerogels, Cabot, Chemat Technology, Compagnie De Saint-Gobain, NTC Nano Tech Coatings, KANSAI HELIOS Group, Heraeus Holding, Parker Chomerics Division |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |