What is Global Conductive 3D Printer Filament Market?

The Global Conductive 3D Printer Filament Market is an emerging sector within the broader 3D printing industry, focusing on materials that can conduct electricity. These specialized filaments are infused with conductive materials, such as carbon or metal particles, allowing them to be used in printing electronic components. This market is gaining traction due to the increasing demand for customized electronic devices and components, which can be efficiently produced using 3D printing technology. Conductive filaments enable the creation of complex geometries and intricate designs that are difficult to achieve with traditional manufacturing methods. They are particularly useful in prototyping and small-scale production, where flexibility and speed are crucial. As industries such as electronics, automotive, and aerospace continue to explore the potential of 3D printing, the demand for conductive filaments is expected to grow. These materials offer a unique combination of electrical conductivity and the versatility of 3D printing, opening up new possibilities for innovation and design. The market is characterized by ongoing research and development efforts aimed at improving the conductivity, strength, and printability of these filaments, making them more accessible and effective for a wide range of applications.

1.75MM, 2.85MM in the Global Conductive 3D Printer Filament Market:

In the Global Conductive 3D Printer Filament Market, filament diameters such as 1.75MM and 2.85MM play a crucial role in determining the compatibility and performance of the filament with different 3D printers. The 1.75MM filament is the most commonly used diameter in the market, favored for its versatility and ease of use. It is compatible with a wide range of 3D printers, making it a popular choice for both hobbyists and professionals. The smaller diameter allows for finer detail and smoother finishes in printed objects, which is particularly important in applications requiring precision, such as electronic components and intricate designs. Additionally, the 1.75MM filament tends to have a faster melting rate, which can lead to quicker print times and more efficient production processes. On the other hand, the 2.85MM filament is often used in industrial and professional settings where larger, more robust prints are required. This larger diameter filament is known for its strength and durability, making it suitable for applications that demand higher mechanical performance. The 2.85MM filament is typically used in high-end 3D printers that are designed to handle larger volumes of material and produce bigger parts. While it may not offer the same level of detail as the 1.75MM filament, it provides greater structural integrity and is ideal for creating functional prototypes and end-use parts. Both filament sizes have their unique advantages and are chosen based on the specific requirements of the project and the capabilities of the 3D printer being used. As the Global Conductive 3D Printer Filament Market continues to evolve, manufacturers are developing new formulations and technologies to enhance the performance of both 1.75MM and 2.85MM filaments. This includes improving the conductivity, flexibility, and strength of the filaments, as well as expanding the range of compatible materials. These advancements are expected to drive further adoption of conductive filaments in various industries, as they offer a cost-effective and efficient solution for producing complex electronic components and devices. The choice between 1.75MM and 2.85MM filaments ultimately depends on the specific needs of the user, the type of 3D printer being used, and the desired properties of the final printed product. As more companies and individuals explore the potential of conductive 3D printing, the demand for both filament sizes is likely to increase, leading to further innovation and growth in the market.

Circuit Board, Sensor, Other in the Global Conductive 3D Printer Filament Market:

The Global Conductive 3D Printer Filament Market finds its applications in various areas, including circuit boards, sensors, and other electronic components. In the realm of circuit boards, conductive filaments offer a revolutionary approach to prototyping and small-scale production. Traditional methods of circuit board manufacturing can be time-consuming and costly, especially when dealing with complex designs or custom requirements. Conductive 3D printing allows for rapid prototyping, enabling designers and engineers to quickly iterate and test their designs. This flexibility is particularly beneficial in the development of custom electronics, where unique configurations and layouts are often required. By using conductive filaments, manufacturers can produce circuit boards with integrated conductive pathways, reducing the need for additional wiring and assembly. This not only streamlines the production process but also enhances the reliability and performance of the final product. In the field of sensors, conductive 3D printer filaments are used to create a wide range of sensing devices, from simple pressure sensors to complex multi-functional sensors. The ability to print conductive materials directly into the sensor design allows for greater customization and integration of multiple sensing elements. This is particularly advantageous in applications where space is limited, or where traditional sensor designs may not be feasible. Conductive 3D printing enables the creation of lightweight, compact, and highly sensitive sensors that can be tailored to specific applications. This technology is being explored in various industries, including automotive, aerospace, and healthcare, where advanced sensing capabilities are increasingly in demand. Beyond circuit boards and sensors, conductive 3D printer filaments are also used in a variety of other applications, such as wearable electronics, smart textiles, and flexible displays. The ability to print conductive materials onto flexible substrates opens up new possibilities for the design and functionality of electronic devices. Wearable electronics, for example, can benefit from the integration of conductive pathways directly into the fabric, allowing for seamless connectivity and enhanced performance. Similarly, flexible displays can be produced with integrated conductive elements, enabling new form factors and interactive features. The versatility of conductive 3D printing makes it an attractive option for innovators and designers looking to push the boundaries of what is possible with electronic devices. As the Global Conductive 3D Printer Filament Market continues to grow, it is expected to drive further advancements in these areas, leading to new applications and opportunities for innovation.

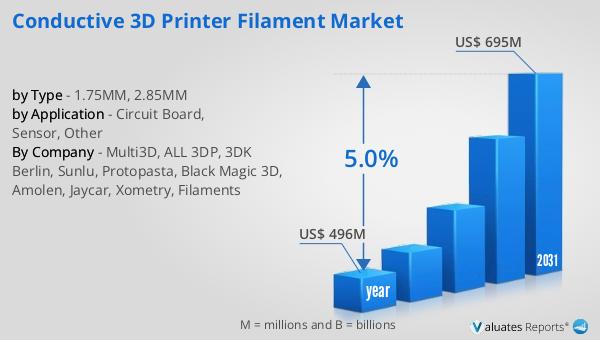

Global Conductive 3D Printer Filament Market Outlook:

The outlook for the Global Conductive 3D Printer Filament Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 496 million, reflecting its significant presence in the 3D printing industry. This market is projected to expand further, reaching an estimated size of US$ 695 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.0% over the forecast period. This upward trend can be attributed to the increasing demand for conductive filaments in various industries, driven by the need for innovative and efficient manufacturing solutions. Conductive 3D printing offers unique advantages, such as the ability to produce complex electronic components with precision and speed, which are highly valued in sectors like electronics, automotive, and aerospace. The market's expansion is also supported by ongoing research and development efforts aimed at enhancing the properties and performance of conductive filaments. As more companies and individuals recognize the potential of this technology, the demand for conductive 3D printer filaments is expected to rise, leading to further growth and innovation in the market. This positive outlook underscores the importance of conductive 3D printing as a transformative force in modern manufacturing.

| Report Metric | Details |

| Report Name | Conductive 3D Printer Filament Market |

| Accounted market size in year | US$ 496 million |

| Forecasted market size in 2031 | US$ 695 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Multi3D, ALL 3DP, 3DK Berlin, Sunlu, Protopasta, Black Magic 3D, Amolen, Jaycar, Xometry, Filaments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |