What is Global Aluminum Radiator Profile Market?

The Global Aluminum Radiator Profile Market is a specialized segment within the broader aluminum industry, focusing on the production and distribution of aluminum profiles specifically designed for radiators. These profiles are essential components in the manufacturing of radiators, which are used in various applications to dissipate heat. Aluminum is favored for this purpose due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. The market encompasses a wide range of products, including different shapes and sizes of profiles that cater to the diverse needs of industries such as automotive, machinery, energy, and household appliances. The demand for aluminum radiator profiles is driven by the increasing need for efficient cooling systems in these sectors, as well as the ongoing trend towards lightweight and energy-efficient materials. As industries continue to innovate and seek more sustainable solutions, the Global Aluminum Radiator Profile Market is expected to grow, offering new opportunities for manufacturers and suppliers. This market is characterized by technological advancements, competitive pricing, and a focus on quality and performance to meet the evolving demands of end-users.

High Pressure Cast Aluminum, Tensile Aluminum Alloy Welding in the Global Aluminum Radiator Profile Market:

High Pressure Cast Aluminum and Tensile Aluminum Alloy Welding are two critical processes in the Global Aluminum Radiator Profile Market, each contributing to the production of high-quality radiator components. High Pressure Cast Aluminum involves the use of high-pressure die casting techniques to produce aluminum parts with precise dimensions and excellent surface finishes. This process is particularly beneficial for manufacturing complex shapes and intricate designs that are often required in radiator profiles. The high pressure ensures that the molten aluminum fills the mold completely, resulting in parts that are dense and free from defects. This method is favored for its efficiency and ability to produce large volumes of parts quickly, making it ideal for industries with high demand for radiator components. On the other hand, Tensile Aluminum Alloy Welding is a process used to join aluminum parts together, ensuring structural integrity and strength. This technique is crucial in the assembly of radiator profiles, where multiple components need to be securely connected to form a complete unit. Welding aluminum alloys requires specialized skills and equipment due to the metal's high thermal conductivity and tendency to form oxides. The process involves using filler materials and precise heat control to create strong, durable joints that can withstand the stresses and strains of operation. In the context of radiator profiles, tensile welding ensures that the assembled units can handle the thermal expansion and contraction that occurs during heating and cooling cycles. Both High Pressure Cast Aluminum and Tensile Aluminum Alloy Welding play vital roles in the production of aluminum radiator profiles, contributing to the overall quality and performance of the final products. Manufacturers in this market must invest in advanced technologies and skilled labor to ensure that their products meet the stringent requirements of their customers. As the demand for lightweight and efficient cooling solutions continues to rise, these processes will remain essential in the development of innovative radiator profiles that cater to the needs of various industries. The integration of these techniques into the manufacturing process not only enhances the durability and functionality of the radiator profiles but also supports the industry's efforts towards sustainability and environmental responsibility.

Machines, Automotive, Energy, Household Appliances, Other in the Global Aluminum Radiator Profile Market:

The Global Aluminum Radiator Profile Market finds its applications across various sectors, including machines, automotive, energy, household appliances, and others, each benefiting from the unique properties of aluminum. In the machinery sector, aluminum radiator profiles are used in industrial equipment and heavy machinery to manage heat dissipation effectively. The lightweight nature of aluminum reduces the overall weight of the machinery, improving efficiency and reducing energy consumption. Additionally, the corrosion-resistant properties of aluminum ensure longevity and reliability, even in harsh operating environments. In the automotive industry, aluminum radiator profiles are integral to the cooling systems of vehicles. As the demand for fuel-efficient and environmentally friendly vehicles increases, manufacturers are turning to aluminum to reduce the weight of their vehicles, thereby improving fuel efficiency. Aluminum radiator profiles offer excellent thermal conductivity, ensuring that engines remain cool and operate efficiently. This is particularly important in high-performance vehicles, where managing heat is crucial to maintaining optimal performance and preventing engine damage. The energy sector also benefits from the use of aluminum radiator profiles, particularly in renewable energy systems such as solar panels and wind turbines. These systems require efficient heat dissipation to maintain performance and prevent overheating. Aluminum's lightweight and durable nature make it an ideal choice for these applications, where weight and reliability are critical factors. In household appliances, aluminum radiator profiles are used in products such as refrigerators, air conditioners, and heaters, where efficient heat exchange is essential for optimal performance. The use of aluminum in these appliances not only improves energy efficiency but also contributes to the overall durability and lifespan of the products. Other industries, such as electronics and telecommunications, also utilize aluminum radiator profiles to manage heat in sensitive equipment. As technology advances and devices become more compact, the need for efficient cooling solutions becomes increasingly important. Aluminum radiator profiles provide an effective solution, ensuring that electronic components remain cool and function reliably. Overall, the versatility and performance of aluminum radiator profiles make them a valuable component in a wide range of applications, supporting the ongoing demand for efficient and sustainable cooling solutions across various industries.

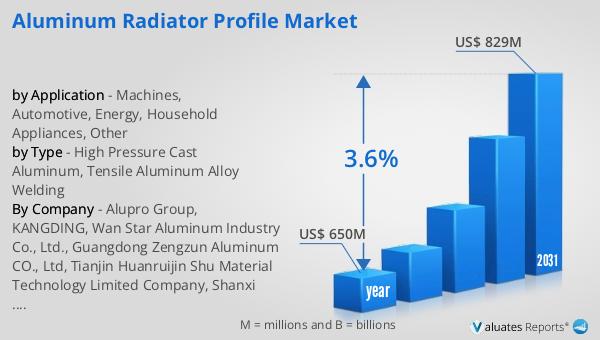

Global Aluminum Radiator Profile Market Outlook:

The global market for Aluminum Radiator Profile was valued at approximately $650 million in 2024, and it is anticipated to grow to a revised size of around $829 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.6% over the forecast period. This upward trend in market value highlights the increasing demand for aluminum radiator profiles across various industries. The growth can be attributed to several factors, including the rising need for efficient cooling systems in automotive, machinery, and energy sectors, as well as the ongoing shift towards lightweight and energy-efficient materials. As industries continue to innovate and seek more sustainable solutions, the demand for high-quality aluminum radiator profiles is expected to rise, driving market growth. Manufacturers and suppliers in this market are likely to benefit from the expanding opportunities, as they continue to develop and offer advanced products that meet the evolving needs of their customers. The market's growth trajectory underscores the importance of aluminum radiator profiles in supporting the development of efficient and sustainable cooling solutions across a wide range of applications.

| Report Metric | Details |

| Report Name | Aluminum Radiator Profile Market |

| Accounted market size in year | US$ 650 million |

| Forecasted market size in 2031 | US$ 829 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alupro Group, KANGDING, Wan Star Aluminum Industry Co., Ltd., Guangdong Zengzun Aluminum CO., Ltd, Tianjin Huanruijin Shu Material Technology Limited Company, Shanxi Bada Magnesium Co., Ltd., Zhangjiagang Xiangyi Aluminum Manufacturing, Foshan Lvtian Aluminum Co., Ltd, Guangdong Xingfa Aluminium Co., Ltd., Shangdong Xinxinan Southwest Light Alloy Technology, Jiangyin Jiayun Aluminium |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |