What is Global Cable Filling Compound Market?

The Global Cable Filling Compound Market is a specialized segment within the broader cable industry, focusing on materials used to fill the spaces within cables to enhance their performance and durability. These compounds are crucial in ensuring that cables, whether used in telecommunications, power transmission, or other applications, remain functional and reliable under various environmental conditions. The primary purpose of cable filling compounds is to prevent the ingress of water and other contaminants, which can cause significant damage and reduce the lifespan of cables. They also help in maintaining the structural integrity of the cables by providing additional support and cushioning to the internal components. The market for these compounds is driven by the increasing demand for high-performance cables in various industries, including telecommunications, energy, and automotive. As technology advances and the need for efficient data transmission grows, the demand for reliable and durable cables, and consequently cable filling compounds, is expected to rise. This market is characterized by a variety of products, each designed to meet specific requirements, such as temperature resistance, flexibility, and environmental safety. Manufacturers in this market are continually innovating to develop compounds that offer enhanced performance while being cost-effective and environmentally friendly.

Filling Type, Flooding Type in the Global Cable Filling Compound Market:

In the Global Cable Filling Compound Market, the filling type and flooding type are two critical categories that cater to different needs and applications. Filling type compounds are primarily used to fill the interstices within cables, providing a barrier against moisture and other environmental factors. These compounds are typically made from materials like petroleum jelly, thixotropic gels, or other synthetic substances that offer excellent water-blocking properties. They are designed to remain stable over a wide range of temperatures, ensuring that the cables remain protected in various climatic conditions. Filling type compounds are particularly important in applications where cables are exposed to harsh environments, such as underground or underwater installations. They help in maintaining the cable's performance by preventing water ingress, which can lead to short circuits or signal loss. On the other hand, flooding type compounds are used to coat the outer surfaces of cables, providing an additional layer of protection against external elements. These compounds are often used in conjunction with filling type compounds to offer comprehensive protection for cables. Flooding type compounds are typically more viscous and are designed to flow into any gaps or spaces on the cable's surface, ensuring complete coverage. They are particularly useful in applications where cables are exposed to mechanical stress or abrasion, as they help in reducing friction and wear. The choice between filling type and flooding type compounds depends on the specific requirements of the application, including the environmental conditions, the type of cable, and the desired level of protection. Both filling and flooding type compounds play a crucial role in enhancing the performance and longevity of cables. They help in maintaining the structural integrity of the cables by providing support and cushioning to the internal components. This is particularly important in applications where cables are subject to mechanical stress or movement, as the compounds help in absorbing shocks and vibrations. Additionally, these compounds contribute to the overall safety of the cables by preventing the ingress of water and other contaminants, which can cause significant damage and reduce the lifespan of the cables. As the demand for high-performance cables continues to grow, the market for filling and flooding type compounds is expected to expand, driven by the need for reliable and durable cable solutions. Manufacturers in the Global Cable Filling Compound Market are continually innovating to develop compounds that offer enhanced performance while being cost-effective and environmentally friendly. This includes the development of new materials and formulations that provide improved water-blocking properties, temperature resistance, and flexibility. Additionally, there is a growing focus on sustainability, with manufacturers looking to develop compounds that are biodegradable or made from renewable resources. This is in response to increasing environmental regulations and the demand for greener products. As a result, the market for filling and flooding type compounds is characterized by a high level of competition and innovation, with manufacturers striving to meet the evolving needs of their customers. In conclusion, the Global Cable Filling Compound Market is a dynamic and rapidly evolving segment within the cable industry. The filling type and flooding type compounds play a crucial role in enhancing the performance and longevity of cables, providing protection against environmental factors and mechanical stress. As the demand for high-performance cables continues to grow, the market for these compounds is expected to expand, driven by the need for reliable and durable cable solutions. Manufacturers are continually innovating to develop compounds that offer enhanced performance while being cost-effective and environmentally friendly, ensuring that the market remains competitive and responsive to the needs of its customers.

Copper Cable, Fiber Optic Cable, Other in the Global Cable Filling Compound Market:

The Global Cable Filling Compound Market finds its usage in various areas, including copper cables, fiber optic cables, and other types of cables. In copper cables, filling compounds are primarily used to prevent the ingress of moisture and other contaminants, which can cause corrosion and reduce the lifespan of the cables. These compounds help in maintaining the electrical performance of the cables by providing a barrier against environmental factors. They also contribute to the structural integrity of the cables by providing support and cushioning to the internal components. This is particularly important in applications where copper cables are exposed to harsh environments, such as underground or underwater installations. The use of filling compounds in copper cables is driven by the need for reliable and durable cable solutions that can withstand various environmental conditions. In fiber optic cables, filling compounds play a crucial role in maintaining the performance and reliability of the cables. These compounds are used to fill the spaces within the cables, providing a barrier against moisture and other contaminants. This is particularly important in fiber optic cables, as the presence of moisture can cause significant signal loss and reduce the efficiency of data transmission. Filling compounds help in maintaining the structural integrity of the cables by providing support and cushioning to the delicate optical fibers. This is essential in applications where fiber optic cables are subject to mechanical stress or movement, as the compounds help in absorbing shocks and vibrations. The use of filling compounds in fiber optic cables is driven by the increasing demand for high-speed data transmission and the need for reliable and durable cable solutions. Apart from copper and fiber optic cables, filling compounds are also used in other types of cables, including coaxial cables, power cables, and specialty cables. In coaxial cables, filling compounds are used to prevent the ingress of moisture and other contaminants, which can cause signal loss and reduce the performance of the cables. In power cables, filling compounds help in maintaining the electrical performance of the cables by providing a barrier against environmental factors. They also contribute to the structural integrity of the cables by providing support and cushioning to the internal components. In specialty cables, filling compounds are used to meet specific requirements, such as temperature resistance, flexibility, and environmental safety. The use of filling compounds in these cables is driven by the need for reliable and durable cable solutions that can withstand various environmental conditions. In conclusion, the Global Cable Filling Compound Market plays a crucial role in enhancing the performance and reliability of various types of cables, including copper cables, fiber optic cables, and other types of cables. These compounds provide protection against environmental factors and mechanical stress, ensuring that the cables remain functional and reliable under various conditions. As the demand for high-performance cables continues to grow, the market for filling compounds is expected to expand, driven by the need for reliable and durable cable solutions. Manufacturers are continually innovating to develop compounds that offer enhanced performance while being cost-effective and environmentally friendly, ensuring that the market remains competitive and responsive to the needs of its customers.

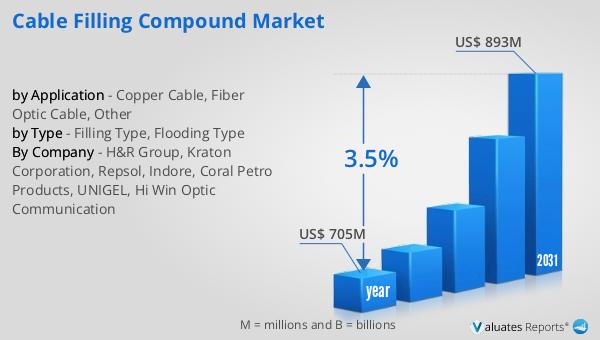

Global Cable Filling Compound Market Outlook:

The global market for Cable Filling Compound was valued at approximately $705 million in 2024. This market is anticipated to grow steadily over the coming years, reaching an estimated size of $893 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.5% during the forecast period. The steady increase in market size reflects the rising demand for high-performance cables across various industries, including telecommunications, energy, and automotive. As these industries continue to expand and evolve, the need for reliable and durable cable solutions becomes increasingly critical. Cable filling compounds play a vital role in enhancing the performance and longevity of cables, providing protection against environmental factors and mechanical stress. This has led to a growing demand for these compounds, driving the market's growth. Additionally, manufacturers are continually innovating to develop compounds that offer enhanced performance while being cost-effective and environmentally friendly. This focus on innovation and sustainability is expected to further fuel the market's growth, ensuring that it remains competitive and responsive to the evolving needs of its customers. As a result, the Global Cable Filling Compound Market is poised for continued expansion, driven by the increasing demand for reliable and durable cable solutions.

| Report Metric | Details |

| Report Name | Cable Filling Compound Market |

| Accounted market size in year | US$ 705 million |

| Forecasted market size in 2031 | US$ 893 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | H&R Group, Kraton Corporation, Repsol, Indore, Coral Petro Products, UNIGEL, Hi Win Optic Communication |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |