What is Global Nano Dense Film Market?

The Global Nano Dense Film Market is a rapidly evolving sector that focuses on the production and application of ultra-thin films at the nanoscale. These films, often just a few nanometers thick, are engineered to possess unique properties that make them highly valuable across various industries. The market is driven by the increasing demand for advanced materials that offer superior performance in terms of strength, flexibility, and conductivity. Nano dense films are used in a wide range of applications, from electronics and energy to healthcare and environmental protection. Their ability to enhance the efficiency and durability of products makes them an attractive option for manufacturers looking to innovate and improve their offerings. As technology continues to advance, the potential for nano dense films to revolutionize traditional materials and processes becomes increasingly apparent, making this market a focal point for research and development efforts worldwide. The growth of this market is supported by ongoing advancements in nanotechnology and material science, which are continually expanding the possibilities for what these films can achieve. With their unique characteristics and broad applicability, nano dense films are poised to play a significant role in the future of material science and engineering.

Liquid Phase Method, Gas Phase Method in the Global Nano Dense Film Market:

The Liquid Phase Method and Gas Phase Method are two primary techniques used in the production of nano dense films, each offering distinct advantages and challenges. The Liquid Phase Method involves the deposition of materials from a liquid solution onto a substrate, forming a thin film. This method is particularly advantageous for its simplicity and cost-effectiveness, making it accessible for a wide range of applications. It allows for precise control over the film's thickness and composition, which is crucial for tailoring the film's properties to specific needs. Techniques such as sol-gel processing, chemical bath deposition, and electrochemical deposition fall under this category. Sol-gel processing, for instance, involves the transition of a solution into a solid gel phase, which is then dried and annealed to form a dense film. This method is highly versatile and can be used to produce films with complex compositions and structures. Chemical bath deposition, on the other hand, involves immersing a substrate in a solution containing the desired film material, which precipitates onto the substrate to form a film. This technique is particularly useful for producing films with uniform thickness and composition. Electrochemical deposition involves the use of an electric current to drive the deposition of material from a solution onto a substrate. This method offers excellent control over the film's thickness and composition, making it ideal for applications requiring high precision. The Gas Phase Method, in contrast, involves the deposition of materials from a vapor phase onto a substrate. This method is known for its ability to produce high-quality films with excellent uniformity and purity. Techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and atomic layer deposition (ALD) are commonly used in this approach. CVD involves the chemical reaction of gaseous precursors on a substrate, resulting in the formation of a solid film. This method is widely used in the semiconductor industry due to its ability to produce films with excellent conformality and uniformity. PVD, on the other hand, involves the physical transfer of material from a source to a substrate in a vacuum environment. This method is highly versatile and can be used to deposit a wide range of materials, including metals, ceramics, and polymers. ALD is a specialized form of CVD that involves the sequential exposure of a substrate to different gaseous precursors, resulting in the formation of a film with atomic-level precision. This method is particularly useful for producing films with complex compositions and structures, making it ideal for applications in advanced electronics and nanotechnology. Both the Liquid Phase Method and Gas Phase Method have their own set of advantages and limitations, and the choice between them often depends on the specific requirements of the application. The Liquid Phase Method is generally more cost-effective and easier to implement, making it suitable for large-scale production of films with relatively simple compositions. However, it may not be suitable for applications requiring films with high purity and uniformity. The Gas Phase Method, on the other hand, is more complex and expensive, but it offers superior control over the film's properties, making it ideal for high-performance applications. As the demand for nano dense films continues to grow, ongoing research and development efforts are focused on improving these methods to enhance their efficiency, scalability, and versatility. Innovations in deposition techniques, precursor materials, and process control are expected to play a crucial role in advancing the capabilities of both the Liquid Phase Method and Gas Phase Method, enabling the production of nano dense films with unprecedented performance and functionality.

Energy, Electronic, Others in the Global Nano Dense Film Market:

The Global Nano Dense Film Market finds extensive usage in various sectors, including energy, electronics, and others, due to the unique properties of these films. In the energy sector, nano dense films are used to enhance the efficiency and performance of solar cells, batteries, and fuel cells. Their ability to improve the conductivity and durability of these devices makes them an attractive option for manufacturers looking to develop more efficient and sustainable energy solutions. For instance, in solar cells, nano dense films can be used to create anti-reflective coatings that increase the amount of light absorbed by the cell, thereby improving its efficiency. In batteries, these films can be used to create protective coatings that enhance the lifespan and performance of the battery by preventing degradation and improving conductivity. In fuel cells, nano dense films can be used to create catalysts that enhance the efficiency of the chemical reactions involved, leading to improved performance and reduced costs. In the electronics sector, nano dense films are used to create advanced components with enhanced performance and functionality. Their ability to provide superior conductivity, flexibility, and durability makes them ideal for use in a wide range of electronic devices, from smartphones and tablets to advanced computing systems. For example, in the production of flexible electronics, nano dense films can be used to create conductive layers that maintain their performance even when bent or stretched. This makes them ideal for use in wearable devices and other applications where flexibility is crucial. In advanced computing systems, nano dense films can be used to create high-performance transistors and other components that offer improved speed and efficiency. Their ability to provide superior thermal management also makes them ideal for use in devices that generate a significant amount of heat, such as high-performance processors and graphics cards. Beyond energy and electronics, nano dense films find applications in various other sectors, including healthcare, environmental protection, and automotive. In healthcare, these films are used to create advanced diagnostic and therapeutic devices with enhanced performance and functionality. For instance, nano dense films can be used to create biosensors with improved sensitivity and specificity, enabling more accurate and reliable detection of diseases. In environmental protection, these films are used to create advanced filtration systems that can remove contaminants from air and water with high efficiency. Their ability to provide superior filtration performance makes them ideal for use in a wide range of applications, from industrial wastewater treatment to air purification systems. In the automotive sector, nano dense films are used to create advanced coatings and components that enhance the performance and durability of vehicles. For example, these films can be used to create anti-corrosion coatings that protect metal surfaces from rust and degradation, thereby extending the lifespan of the vehicle. They can also be used to create advanced sensors and electronic components that improve the performance and safety of vehicles. Overall, the unique properties of nano dense films make them highly valuable across a wide range of industries, and their usage is expected to continue to grow as technology advances and new applications are developed. The ability of these films to enhance the performance and functionality of products makes them an attractive option for manufacturers looking to innovate and improve their offerings. As research and development efforts continue to advance the capabilities of nano dense films, their potential to revolutionize traditional materials and processes becomes increasingly apparent, making them a key focus for the future of material science and engineering.

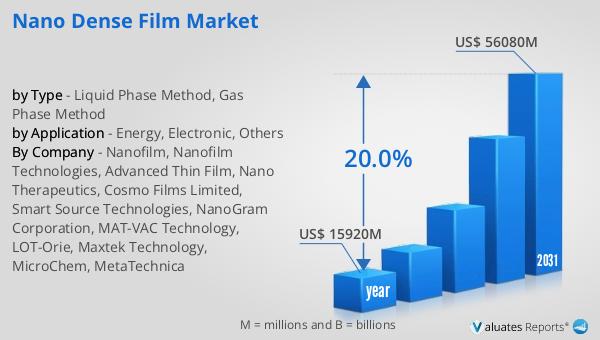

Global Nano Dense Film Market Outlook:

The global market for Nano Dense Film was valued at $15,920 million in 2024, and it is anticipated to expand significantly, reaching an estimated size of $56,080 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 20.0% over the forecast period. The substantial increase in market size underscores the growing demand for nano dense films across various industries, driven by their unique properties and wide range of applications. As industries continue to seek advanced materials that offer superior performance, the demand for nano dense films is expected to rise, contributing to the market's robust growth. The projected expansion of the market reflects the increasing recognition of the value that nano dense films bring to various sectors, from energy and electronics to healthcare and environmental protection. With ongoing advancements in nanotechnology and material science, the potential for nano dense films to revolutionize traditional materials and processes is becoming increasingly apparent, making this market a focal point for research and development efforts worldwide. The impressive growth rate of the market highlights the significant opportunities that exist for companies operating in this space, as they seek to capitalize on the increasing demand for innovative and high-performance materials.

| Report Metric | Details |

| Report Name | Nano Dense Film Market |

| Accounted market size in year | US$ 15920 million |

| Forecasted market size in 2031 | US$ 56080 million |

| CAGR | 20.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nanofilm, Nanofilm Technologies, Advanced Thin Film, Nano Therapeutics, Cosmo Films Limited, Smart Source Technologies, NanoGram Corporation, MAT-VAC Technology, LOT-Orie, Maxtek Technology, MicroChem, MetaTechnica |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |