What is Global Ceramic Injection Molding Materials Market?

The Global Ceramic Injection Molding Materials Market is a specialized segment within the broader materials industry, focusing on the production and application of ceramic materials through the injection molding process. This market is characterized by its ability to produce complex and high-precision ceramic components that are used in a variety of industries. Ceramic injection molding (CIM) combines the versatility of plastic injection molding with the high-performance characteristics of ceramics, such as high temperature resistance, hardness, and wear resistance. The process involves mixing ceramic powders with a binder material to form a feedstock, which is then injected into a mold to form the desired shape. After molding, the binder is removed, and the ceramic part is sintered to achieve its final properties. This market is driven by the demand for miniaturized and intricate components in sectors such as electronics, automotive, medical, and aerospace. The ability to produce parts with tight tolerances and complex geometries makes CIM an attractive manufacturing method for high-performance applications. As industries continue to push the boundaries of technology and performance, the Global Ceramic Injection Molding Materials Market is poised for growth, offering innovative solutions to meet the evolving needs of various sectors.

Oxide Ceramics, Non-oxide Ceramics, Composite Materials in the Global Ceramic Injection Molding Materials Market:

Oxide ceramics, non-oxide ceramics, and composite materials are the primary categories within the Global Ceramic Injection Molding Materials Market, each offering unique properties and applications. Oxide ceramics, such as alumina and zirconia, are known for their excellent thermal stability, electrical insulation, and resistance to corrosion and wear. Alumina, one of the most widely used oxide ceramics, is valued for its hardness and high melting point, making it suitable for applications in electronics, cutting tools, and wear-resistant components. Zirconia, on the other hand, is prized for its toughness and is often used in dental implants and other medical applications due to its biocompatibility. Non-oxide ceramics, including carbides, nitrides, and borides, offer superior hardness and thermal conductivity compared to oxide ceramics. Silicon carbide and silicon nitride are prominent examples, with applications in high-temperature environments, such as engine components and cutting tools. These materials are also used in the semiconductor industry due to their electrical properties. Composite materials in the CIM market combine the benefits of different ceramic types or integrate ceramics with other materials to enhance performance. These composites can be tailored to achieve specific properties, such as improved toughness, thermal shock resistance, or electrical conductivity. For instance, ceramic matrix composites (CMCs) are used in aerospace applications for their lightweight and high-temperature capabilities. The choice of material depends on the specific requirements of the application, including mechanical properties, thermal stability, and cost considerations. The development of new ceramic materials and composites continues to expand the possibilities within the CIM market, enabling the production of components that meet the demanding needs of modern industries. As technology advances, the demand for high-performance materials in sectors such as electronics, automotive, and aerospace is expected to drive further innovation and growth in the Global Ceramic Injection Molding Materials Market.

Medical and Dental, Textile Industry, Automotive, Electrical, Household Appliances, Other in the Global Ceramic Injection Molding Materials Market:

The Global Ceramic Injection Molding Materials Market finds extensive usage across various industries, including medical and dental, textile, automotive, electrical, household appliances, and others. In the medical and dental sectors, ceramic injection molding is used to produce components such as dental implants, surgical tools, and prosthetic devices. The biocompatibility, strength, and wear resistance of ceramics make them ideal for these applications, where precision and reliability are critical. In the textile industry, ceramic components are used in machinery and equipment that require high wear resistance and durability, such as thread guides and cutting tools. The automotive industry benefits from ceramic injection molding through the production of lightweight and high-performance components, such as engine parts, sensors, and exhaust systems. Ceramics offer excellent thermal and chemical stability, making them suitable for harsh environments and high-temperature applications. In the electrical industry, ceramics are used for their insulating properties in components like insulators, capacitors, and substrates for electronic circuits. Household appliances also utilize ceramic components for their durability and heat resistance, such as in heating elements and wear-resistant parts. Other industries, including aerospace and defense, leverage the unique properties of ceramics for applications that require high strength-to-weight ratios and resistance to extreme conditions. The versatility and performance of ceramic injection molding materials make them a valuable choice for a wide range of applications, driving their adoption across multiple sectors. As industries continue to seek materials that offer superior performance and reliability, the Global Ceramic Injection Molding Materials Market is expected to play a crucial role in meeting these demands.

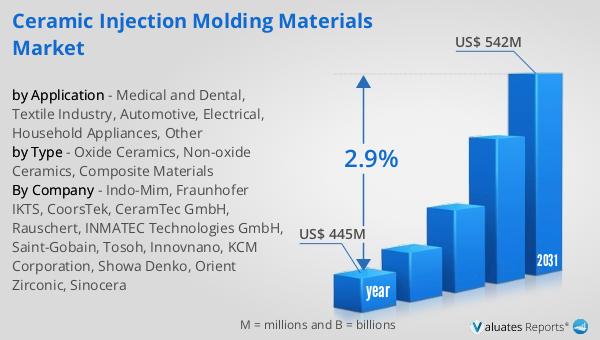

Global Ceramic Injection Molding Materials Market Outlook:

The global market for Ceramic Injection Molding Materials was valued at approximately $445 million in 2024, with projections indicating a growth to around $542 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.9% over the forecast period. This market expansion is driven by the increasing demand for high-performance ceramic components across various industries, including automotive, electronics, and medical. The ability of ceramic injection molding to produce complex and precise parts with superior material properties makes it an attractive option for manufacturers seeking to enhance product performance and reliability. As industries continue to innovate and push the boundaries of technology, the demand for advanced materials like ceramics is expected to rise. The growth in this market also reflects the ongoing advancements in ceramic materials and processing technologies, which enable the production of components that meet the stringent requirements of modern applications. With the continued focus on sustainability and efficiency, the Global Ceramic Injection Molding Materials Market is poised to play a significant role in the development of next-generation products and technologies. The projected growth underscores the importance of ceramic materials in addressing the evolving needs of various industries and highlights the potential for further innovation and expansion in this dynamic market.

| Report Metric | Details |

| Report Name | Ceramic Injection Molding Materials Market |

| Accounted market size in year | US$ 445 million |

| Forecasted market size in 2031 | US$ 542 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Indo-Mim, Fraunhofer IKTS, CoorsTek, CeramTec GmbH, Rauschert, INMATEC Technologies GmbH, Saint-Gobain, Tosoh, Innovnano, KCM Corporation, Showa Denko, Orient Zirconic, Sinocera |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |