What is Global Plasma Water Table Fluid Market?

The Global Plasma Water Table Fluid Market is an intriguing segment within the broader industrial fluids market, primarily used in plasma cutting tables. Plasma cutting is a process that involves cutting through electrically conductive materials using an accelerated jet of hot plasma. The plasma water table fluid plays a crucial role in this process by cooling and stabilizing the plasma arc, reducing the risk of warping the material being cut, and minimizing the production of hazardous fumes. This fluid is specifically formulated to enhance the efficiency and safety of plasma cutting operations. It is designed to withstand high temperatures and provide optimal thermal conductivity, ensuring that the cutting process is smooth and precise. The market for this fluid is driven by the increasing demand for precision cutting in industries such as automotive, aerospace, and construction. As these industries continue to grow, the need for efficient and reliable cutting solutions becomes more pronounced, thereby boosting the demand for plasma water table fluids. Additionally, advancements in plasma cutting technology and the development of more environmentally friendly fluid formulations are expected to further propel the market. The global plasma water table fluid market is characterized by a diverse range of products tailored to meet the specific needs of different applications and industries.

Bottled, Barreled in the Global Plasma Water Table Fluid Market:

In the Global Plasma Water Table Fluid Market, bottled and barreled products play a significant role in meeting the diverse needs of various industries. Bottled plasma water table fluids are typically packaged in smaller quantities, making them ideal for businesses with limited space or those that require precise amounts for specific applications. These bottles are often designed for easy handling and storage, ensuring that the fluid remains uncontaminated and ready for use. The convenience of bottled fluids is particularly beneficial for small to medium-sized enterprises that may not have the infrastructure to handle large volumes of fluid. On the other hand, barreled plasma water table fluids are packaged in larger quantities, usually in drums or barrels, catering to industries with high-volume requirements. These barrels are designed to facilitate bulk handling and storage, making them suitable for large-scale operations such as manufacturing plants and heavy industries. The choice between bottled and barreled fluids often depends on the scale of operations, budget constraints, and specific application needs. For instance, a large automotive manufacturing plant may prefer barreled fluids due to their cost-effectiveness and ease of integration into automated systems. Conversely, a small metalworking shop might opt for bottled fluids to maintain flexibility and control over their usage. Both bottled and barreled plasma water table fluids are formulated to meet stringent quality standards, ensuring that they provide optimal performance in plasma cutting applications. They are designed to enhance the cutting process by improving thermal conductivity, reducing the risk of material distortion, and minimizing the production of harmful fumes. The packaging of these fluids also plays a crucial role in maintaining their quality and effectiveness. Bottled fluids are often equipped with tamper-proof seals and easy-pour spouts to prevent contamination and spillage. Barreled fluids, on the other hand, are typically fitted with secure lids and dispensing systems to facilitate safe and efficient handling. The market for bottled and barreled plasma water table fluids is influenced by several factors, including technological advancements, environmental regulations, and industry-specific requirements. As plasma cutting technology continues to evolve, there is a growing demand for fluids that can keep pace with these advancements. This has led to the development of new formulations that offer improved performance and environmental benefits. For example, some manufacturers are focusing on creating biodegradable and non-toxic fluids that reduce the environmental impact of plasma cutting operations. Additionally, the increasing emphasis on workplace safety and regulatory compliance is driving the demand for fluids that minimize the production of hazardous fumes and improve air quality in industrial settings. The choice between bottled and barreled fluids also reflects broader trends in the market, such as the shift towards more sustainable and efficient manufacturing practices. Companies are increasingly looking for solutions that not only enhance their operational efficiency but also align with their sustainability goals. This has led to a growing interest in plasma water table fluids that offer both performance and environmental benefits. In conclusion, the Global Plasma Water Table Fluid Market offers a range of bottled and barreled products designed to meet the diverse needs of different industries. Whether it's the convenience and precision of bottled fluids or the cost-effectiveness and scalability of barreled fluids, businesses have a variety of options to choose from. As the market continues to evolve, the focus on innovation, sustainability, and regulatory compliance will play a key role in shaping the future of plasma water table fluids.

Direct Selling, Distributor in the Global Plasma Water Table Fluid Market:

The Global Plasma Water Table Fluid Market finds significant usage in areas such as direct selling and distribution, each playing a crucial role in ensuring that these specialized fluids reach their intended users efficiently. Direct selling involves manufacturers or suppliers selling plasma water table fluids directly to end-users, bypassing traditional retail channels. This approach allows for a more personalized sales experience, where manufacturers can directly address the specific needs and concerns of their customers. Direct selling is particularly beneficial in the plasma water table fluid market, as it enables manufacturers to provide technical support and guidance to users, ensuring that they select the right fluid for their specific plasma cutting applications. This direct interaction also allows manufacturers to gather valuable feedback from users, which can be used to improve product formulations and address emerging market needs. On the other hand, distributors play a vital role in the plasma water table fluid market by acting as intermediaries between manufacturers and end-users. Distributors typically purchase fluids in bulk from manufacturers and then sell them to various customers, including industrial facilities, workshops, and retailers. This distribution model allows manufacturers to reach a wider audience without having to manage the complexities of direct sales. Distributors often have established networks and relationships within specific industries, enabling them to effectively market and sell plasma water table fluids to targeted customers. They also provide logistical support, ensuring that products are delivered efficiently and on time. The choice between direct selling and distribution often depends on the manufacturer's business model, target market, and resources. Direct selling may be more suitable for manufacturers with a niche product offering or those looking to build strong relationships with their customers. In contrast, distribution may be more appropriate for manufacturers aiming to reach a broader market or those with limited sales and marketing resources. Both direct selling and distribution have their advantages and challenges. Direct selling allows for greater control over the sales process and customer relationships, but it can be resource-intensive and may limit market reach. Distribution, on the other hand, offers scalability and access to established networks, but it may result in less direct interaction with end-users. In the Global Plasma Water Table Fluid Market, both direct selling and distribution are essential for ensuring that these specialized fluids reach their intended users efficiently. Manufacturers must carefully consider their sales strategy and choose the approach that best aligns with their business goals and market conditions. As the market continues to evolve, the role of direct selling and distribution will remain critical in driving the growth and adoption of plasma water table fluids across various industries.

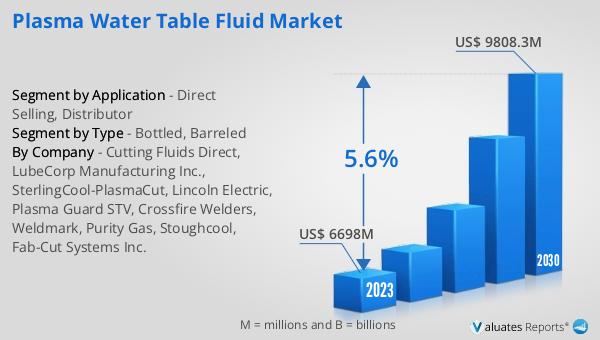

Global Plasma Water Table Fluid Market Outlook:

The outlook for the Global Plasma Water Table Fluid Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $7.43 billion, reflecting its significant role in industries that rely on plasma cutting technology. Looking ahead, the market is expected to expand further, reaching an estimated size of $10.82 billion by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 5.6% over the forecast period. This upward trend can be attributed to several factors, including the increasing demand for precision cutting solutions in industries such as automotive, aerospace, and construction. As these industries continue to grow and evolve, the need for efficient and reliable plasma cutting fluids becomes more pronounced. Additionally, advancements in plasma cutting technology and the development of more environmentally friendly fluid formulations are expected to further propel the market. The focus on sustainability and regulatory compliance is also driving the demand for fluids that minimize the production of hazardous fumes and improve air quality in industrial settings. As a result, the Global Plasma Water Table Fluid Market is poised for continued growth, offering a range of opportunities for manufacturers, distributors, and end-users alike.

| Report Metric | Details |

| Report Name | Plasma Water Table Fluid Market |

| Accounted market size in year | US$ 7430 million |

| Forecasted market size in 2031 | US$ 10820 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cutting Fluids Direct, LubeCorp Manufacturing Inc., SterlingCool-PlasmaCut, Lincoln Electric, Plasma Guard STV, Crossfire Welders, Weldmark, Purity Gas, Stoughcool, Fab-Cut Systems Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |