What is Global Urine-Diverting Dry Toilet (UDDT) Market?

The Global Urine-Diverting Dry Toilet (UDDT) Market is an innovative segment within the sanitation industry that focuses on sustainable and eco-friendly waste management solutions. UDDTs are designed to separate urine from feces at the source, which not only reduces water usage but also facilitates the recycling of nutrients. This separation process is crucial as it allows for the safe and efficient treatment of human waste, transforming it into valuable resources such as fertilizers. The market for UDDTs is driven by increasing environmental awareness, the need for water conservation, and the demand for sustainable sanitation solutions in both developed and developing regions. These toilets are particularly beneficial in areas with limited water resources or inadequate sewage systems, as they do not require water for flushing. The UDDT market is expanding as more communities and organizations recognize the importance of sustainable waste management practices and the role these toilets can play in achieving environmental goals. As a result, the market is witnessing innovations in design and technology to enhance the efficiency and user-friendliness of these systems.

Self-contained Composting Toilet, Split Composting Toilet in the Global Urine-Diverting Dry Toilet (UDDT) Market:

Self-contained composting toilets and split composting toilets are two prominent types of systems within the Global Urine-Diverting Dry Toilet (UDDT) Market. Self-contained composting toilets are compact units where the composting process occurs within the toilet itself. These systems are ideal for locations where space is limited, such as in tiny homes, cabins, or boats. They are designed to be user-friendly and require minimal maintenance, making them a popular choice for individuals seeking a sustainable and convenient sanitation solution. The composting process in these toilets involves the aerobic breakdown of waste, facilitated by the presence of oxygen and microorganisms. This process not only reduces the volume of waste but also eliminates pathogens, resulting in a safe and nutrient-rich compost that can be used as a soil conditioner. On the other hand, split composting toilets separate the composting chamber from the toilet unit. This design is often used in larger installations, such as in eco-villages or off-grid communities, where there is more space available for the composting process. The separation allows for larger composting volumes and longer retention times, which can enhance the efficiency of the composting process. Split systems often incorporate features such as ventilation systems to control odors and moisture levels, ensuring a pleasant user experience. Both self-contained and split composting toilets contribute to the sustainability goals of the UDDT market by reducing water usage and promoting the recycling of nutrients. They are particularly valuable in areas where traditional sewage systems are not feasible or where water conservation is a priority. As the demand for eco-friendly sanitation solutions grows, these composting toilet systems are likely to see increased adoption across various sectors. The market is also witnessing advancements in materials and technology to improve the durability and performance of these systems, making them more accessible and appealing to a broader audience.

Residential, Commercial, RVs and Camper Vans, Others in the Global Urine-Diverting Dry Toilet (UDDT) Market:

The usage of Global Urine-Diverting Dry Toilets (UDDTs) spans across various sectors, including residential, commercial, recreational vehicles (RVs) and camper vans, and other applications. In residential settings, UDDTs offer an eco-friendly alternative to traditional flush toilets, particularly in areas with limited water resources or inadequate sewage infrastructure. Homeowners who are environmentally conscious or living off-grid often opt for UDDTs to reduce their water footprint and recycle nutrients back into the soil. These toilets are designed to be user-friendly and can be integrated into existing homes or new constructions with relative ease. In commercial settings, UDDTs are increasingly being adopted in eco-friendly buildings, schools, and public facilities. They provide a sustainable sanitation solution that aligns with green building certifications and environmental standards. Businesses and institutions that prioritize sustainability can benefit from the reduced water usage and waste management costs associated with UDDTs. Additionally, these toilets can enhance the environmental credentials of a company or organization, appealing to environmentally conscious customers and stakeholders. In the realm of recreational vehicles (RVs) and camper vans, UDDTs offer a practical solution for travelers seeking to minimize their environmental impact. These toilets are compact and do not require a connection to a sewage system, making them ideal for mobile applications. They allow travelers to enjoy the convenience of a toilet without the need for frequent emptying of waste tanks, as the separated waste can be composted or disposed of more easily. Other applications of UDDTs include use in remote or rural areas, disaster relief situations, and temporary installations such as festivals or construction sites. In these contexts, UDDTs provide a reliable and sustainable sanitation solution where traditional infrastructure may be lacking or impractical. The versatility and environmental benefits of UDDTs make them a valuable addition to a wide range of settings, contributing to the global efforts towards sustainable development and resource conservation.

Global Urine-Diverting Dry Toilet (UDDT) Market Outlook:

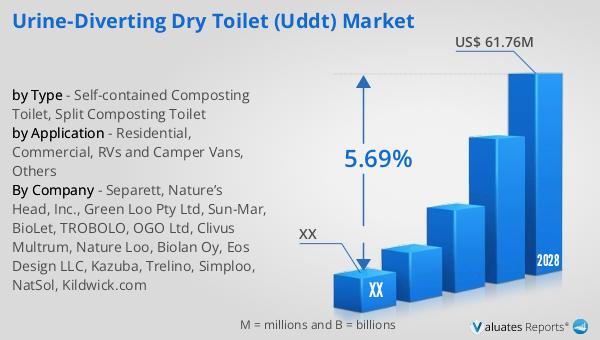

The COVID-19 pandemic has had a significant impact on various industries, including the Global Urine-Diverting Dry Toilet (UDDT) Market. The global composting toilet market, which includes UDDTs, was valued at approximately US$ 44.30 million in 2022. Despite the challenges posed by the pandemic, the market is projected to grow, reaching an estimated value of US$ 61.76 million by 2028. This growth represents a compound annual growth rate (CAGR) of 5.69% during the review period. The pandemic has heightened awareness of hygiene and sanitation, driving demand for sustainable and self-sufficient sanitation solutions like UDDTs. As people become more conscious of their environmental impact and the importance of resource conservation, the adoption of eco-friendly toilets is expected to increase. The market's growth is also supported by innovations in design and technology, which enhance the functionality and appeal of UDDTs. As the world continues to navigate the challenges of the pandemic, the UDDT market is poised to play a crucial role in promoting sustainable sanitation practices and supporting global health and environmental goals.

| Report Metric | Details |

| Report Name | Urine-Diverting Dry Toilet (UDDT) Market |

| Forecasted market size in 2028 | US$ 61.76 million |

| CAGR | 5.69% |

| Forecasted years | 2025 - 2028 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Separett, Nature’s Head, Inc., Green Loo Pty Ltd, Sun-Mar, BioLet, TROBOLO, OGO Ltd, Clivus Multrum, Nature Loo, Biolan Oy, Eos Design LLC, Kazuba, Trelino, Simploo, NatSol, Kildwick.com |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |