What is Global High Temperature Resistant Composite Resin Market?

The Global High Temperature Resistant Composite Resin Market is a specialized segment within the broader composite materials industry, focusing on resins that can withstand extreme temperatures. These resins are crucial in applications where materials are exposed to high heat, such as in aerospace, automotive, and electronics industries. The market is driven by the increasing demand for lightweight, durable materials that can maintain their structural integrity under high thermal stress. High temperature resistant composite resins are engineered to offer superior thermal stability, mechanical strength, and chemical resistance, making them ideal for use in harsh environments. The market is characterized by continuous innovation and development, with manufacturers striving to enhance the performance characteristics of these resins to meet the evolving needs of various industries. As industries continue to push the boundaries of performance and efficiency, the demand for high temperature resistant composite resins is expected to grow, driven by advancements in technology and the increasing adoption of these materials in new applications. The market is also influenced by regulatory standards and environmental considerations, which drive the development of more sustainable and eco-friendly resin solutions.

Polyimide Resin, Maleimide Resin, Cyanate Resin, Other in the Global High Temperature Resistant Composite Resin Market:

Polyimide resin is a key player in the Global High Temperature Resistant Composite Resin Market, known for its exceptional thermal stability and mechanical properties. These resins can withstand temperatures exceeding 260°C, making them ideal for high-performance applications in aerospace and electronics. Polyimide resins are often used in the production of circuit boards, wire insulation, and other components that require high heat resistance. Their ability to maintain structural integrity under extreme conditions makes them indispensable in industries where reliability and performance are critical. Maleimide resin, on the other hand, is valued for its excellent thermal and chemical resistance. These resins are often used in applications that require long-term durability and stability, such as in the automotive and aerospace sectors. Maleimide resins are known for their ability to withstand harsh environmental conditions, making them suitable for use in components exposed to high temperatures and aggressive chemicals. Cyanate resin is another important type of high temperature resistant composite resin, offering a unique combination of thermal stability, low moisture absorption, and excellent dielectric properties. These resins are commonly used in the electronics industry, where they are employed in the production of printed circuit boards and other components that require high thermal and electrical performance. Cyanate resins are also used in aerospace applications, where their low outgassing properties make them ideal for use in space environments. Other types of high temperature resistant composite resins include epoxy and phenolic resins, which are used in a variety of applications due to their excellent mechanical properties and thermal stability. Epoxy resins are widely used in the aerospace and automotive industries, where they are employed in the production of lightweight, high-strength components. Phenolic resins, on the other hand, are known for their flame retardant properties and are often used in applications where fire resistance is a critical requirement. The Global High Temperature Resistant Composite Resin Market is characterized by a diverse range of resin types, each offering unique properties and benefits that make them suitable for specific applications. As industries continue to demand materials that can withstand higher temperatures and harsher environments, the development and adoption of high temperature resistant composite resins are expected to grow, driven by advancements in technology and the increasing need for high-performance materials.

Aerospace, Transportation, Electrical and Electronics, Other in the Global High Temperature Resistant Composite Resin Market:

The usage of Global High Temperature Resistant Composite Resin Market in various industries is extensive and diverse, reflecting the unique properties and benefits of these materials. In the aerospace industry, high temperature resistant composite resins are used in the production of aircraft components that require high thermal stability and mechanical strength. These resins are employed in the manufacture of engine parts, structural components, and interior fittings, where their ability to withstand extreme temperatures and harsh environmental conditions is critical. The lightweight nature of these resins also contributes to fuel efficiency and performance, making them an essential material in modern aerospace engineering. In the transportation sector, high temperature resistant composite resins are used in the production of automotive components that require high heat resistance and durability. These resins are employed in the manufacture of engine parts, exhaust systems, and other components that are exposed to high temperatures and mechanical stress. The use of these resins in the automotive industry is driven by the need for lightweight, high-performance materials that can enhance fuel efficiency and reduce emissions. In the electrical and electronics industry, high temperature resistant composite resins are used in the production of components that require high thermal and electrical performance. These resins are employed in the manufacture of printed circuit boards, wire insulation, and other components that are exposed to high temperatures and electrical stress. The use of these resins in the electronics industry is driven by the need for materials that can withstand the high temperatures and harsh conditions associated with modern electronic devices. Other industries that use high temperature resistant composite resins include the construction and marine sectors, where these materials are employed in the production of components that require high thermal stability and mechanical strength. The use of these resins in these industries is driven by the need for materials that can withstand harsh environmental conditions and provide long-term durability and performance. As industries continue to demand materials that can withstand higher temperatures and harsher environments, the usage of high temperature resistant composite resins is expected to grow, driven by advancements in technology and the increasing need for high-performance materials.

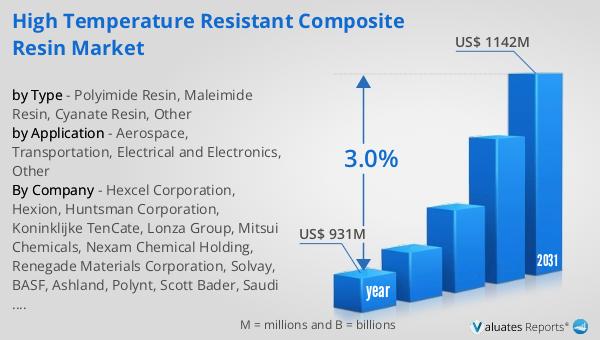

Global High Temperature Resistant Composite Resin Market Outlook:

The global market for High Temperature Resistant Composite Resin was valued at approximately $931 million in 2024. This market is anticipated to expand, reaching an estimated size of $1,142 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.0% over the forecast period. The steady increase in market size underscores the rising demand for materials that can endure extreme temperatures across various industries. This demand is fueled by the need for advanced materials that offer superior thermal stability, mechanical strength, and chemical resistance. As industries such as aerospace, automotive, and electronics continue to evolve, the requirement for high-performance materials that can withstand harsh conditions becomes increasingly critical. The projected growth of the market indicates a positive outlook for manufacturers and suppliers of high temperature resistant composite resins, as they continue to innovate and develop new solutions to meet the evolving needs of their customers. The market's expansion is also influenced by regulatory standards and environmental considerations, which drive the development of more sustainable and eco-friendly resin solutions. As the market continues to grow, it presents significant opportunities for companies to capitalize on the increasing demand for high temperature resistant composite resins and expand their presence in this dynamic and rapidly evolving industry.

| Report Metric | Details |

| Report Name | High Temperature Resistant Composite Resin Market |

| Accounted market size in year | US$ 931 million |

| Forecasted market size in 2031 | US$ 1142 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hexcel Corporation, Hexion, Huntsman Corporation, Koninklijke TenCate, Lonza Group, Mitsui Chemicals, Nexam Chemical Holding, Renegade Materials Corporation, Solvay, BASF, Ashland, Polynt, Scott Bader, Saudi Basic Industries, Mader Composites |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |