What is Global Anti-Corrosion Coating for Building Steel Structure Market?

The Global Anti-Corrosion Coating for Building Steel Structure Market is a specialized segment within the broader coatings industry, focusing on products designed to protect steel structures from corrosion. Corrosion is a natural process that deteriorates metals, leading to structural weaknesses and potential failures. This market is crucial because steel is a primary material used in construction due to its strength and durability. However, steel is also highly susceptible to corrosion, especially in environments exposed to moisture, chemicals, or saltwater. Anti-corrosion coatings serve as a protective barrier, extending the lifespan of steel structures and reducing maintenance costs. These coatings are applied to various steel structures, including buildings, bridges, and industrial facilities, to prevent rust and degradation. The market is driven by the increasing demand for durable infrastructure and the need to protect investments in construction. Technological advancements have led to the development of more effective coatings that offer longer-lasting protection and are environmentally friendly. As urbanization and industrialization continue to rise globally, the demand for anti-corrosion coatings is expected to grow, making this market a vital component of the construction and infrastructure sectors.

Metal Anti-corrosion Coating, Anti-corrosion Coatings Resistant to Seawater Intrusion in the Global Anti-Corrosion Coating for Building Steel Structure Market:

Metal anti-corrosion coatings are essential in protecting steel structures from the damaging effects of corrosion. These coatings are formulated to create a barrier between the metal surface and environmental factors that cause corrosion, such as moisture, oxygen, and salts. The coatings are typically applied in layers, with each layer serving a specific purpose, such as adhesion, protection, and aesthetic appeal. The base layer, often a primer, ensures that the coating adheres well to the metal surface. The intermediate layers provide the bulk of the protection, while the topcoat offers additional protection and can be customized for color and finish. Anti-corrosion coatings resistant to seawater intrusion are particularly important for structures located near or in marine environments. Seawater is highly corrosive due to its salt content, which accelerates the corrosion process. Coatings designed for these environments must be highly resistant to saltwater and able to withstand the harsh conditions of marine settings. These coatings often incorporate advanced materials, such as epoxy, polyurethane, or zinc-rich formulations, which provide superior protection against seawater intrusion. The Global Anti-Corrosion Coating for Building Steel Structure Market is driven by the need to protect valuable infrastructure investments from the costly effects of corrosion. As the demand for durable and long-lasting structures increases, so does the need for effective anti-corrosion solutions. The market is characterized by continuous innovation, with manufacturers developing new formulations that offer improved performance and environmental benefits. For example, water-based coatings are gaining popularity due to their lower environmental impact compared to traditional solvent-based coatings. Additionally, the market is seeing a trend towards the use of nanotechnology in coatings, which enhances their protective properties and extends the lifespan of steel structures. The application of anti-corrosion coatings is a critical step in the construction and maintenance of steel structures. Proper application ensures that the coatings perform as intended and provide the desired level of protection. This involves surface preparation, which may include cleaning, blasting, or priming the metal surface to ensure optimal adhesion. The coatings are then applied using various methods, such as spraying, brushing, or dipping, depending on the specific requirements of the project. The effectiveness of anti-corrosion coatings is influenced by several factors, including the quality of the coating, the application process, and the environmental conditions to which the structure is exposed. Regular inspection and maintenance are also important to ensure that the coatings remain intact and continue to provide protection over time. In summary, metal anti-corrosion coatings play a vital role in preserving the integrity and longevity of steel structures. They offer a cost-effective solution to the challenges posed by corrosion, helping to extend the lifespan of infrastructure and reduce maintenance costs. As the Global Anti-Corrosion Coating for Building Steel Structure Market continues to evolve, it will be shaped by technological advancements, environmental considerations, and the growing demand for durable construction materials.

Houses, Bridge, Others in the Global Anti-Corrosion Coating for Building Steel Structure Market:

The usage of Global Anti-Corrosion Coating for Building Steel Structure Market in various areas such as houses, bridges, and others is crucial for maintaining the integrity and longevity of these structures. In residential buildings, anti-corrosion coatings are applied to steel components to prevent rust and degradation. This is particularly important in areas with high humidity or exposure to saltwater, where the risk of corrosion is higher. By protecting steel structures from corrosion, these coatings help ensure the safety and durability of homes, reducing the need for costly repairs and maintenance. In the case of bridges, anti-corrosion coatings are essential for preserving the structural integrity of these critical infrastructures. Bridges are often exposed to harsh environmental conditions, including moisture, salt, and pollutants, which can accelerate the corrosion process. Applying anti-corrosion coatings to the steel components of bridges helps prevent rust and deterioration, extending the lifespan of the structure and ensuring the safety of those who use it. The coatings used for bridges are typically more robust and durable, designed to withstand the extreme conditions they are exposed to. In addition to houses and bridges, anti-corrosion coatings are used in a variety of other applications, including industrial facilities, pipelines, and offshore structures. In industrial settings, steel structures are often exposed to chemicals and other corrosive substances, making anti-corrosion coatings essential for protecting these assets. Pipelines, which transport oil, gas, and other materials, are also at risk of corrosion, particularly when buried underground or submerged in water. Anti-corrosion coatings help prevent leaks and failures, ensuring the safe and efficient operation of these systems. Offshore structures, such as oil rigs and wind turbines, are exposed to some of the harshest environmental conditions, including saltwater, wind, and waves. Anti-corrosion coatings designed for these applications must be highly resistant to seawater intrusion and able to withstand the constant exposure to the elements. The Global Anti-Corrosion Coating for Building Steel Structure Market plays a vital role in protecting these valuable assets, helping to extend their lifespan and reduce maintenance costs. In summary, the usage of anti-corrosion coatings in houses, bridges, and other applications is essential for maintaining the safety, durability, and longevity of steel structures. These coatings provide a cost-effective solution to the challenges posed by corrosion, helping to protect valuable infrastructure investments and reduce the need for costly repairs and maintenance. As the demand for durable and long-lasting structures continues to grow, the Global Anti-Corrosion Coating for Building Steel Structure Market will play an increasingly important role in the construction and maintenance of these critical assets.

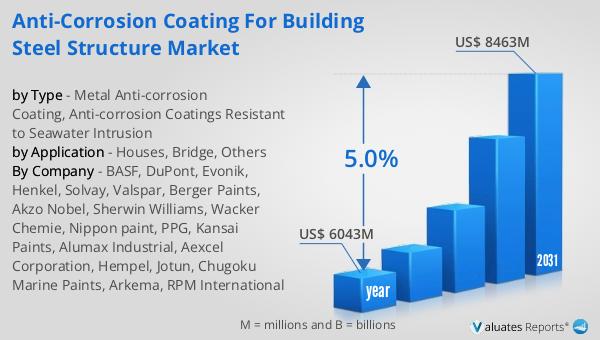

Global Anti-Corrosion Coating for Building Steel Structure Market Outlook:

The global market for Anti-Corrosion Coating for Building Steel Structure was valued at $6,043 million in 2024 and is anticipated to expand to a revised size of $8,463 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period. This growth trajectory underscores the increasing demand for protective coatings that safeguard steel structures from the detrimental effects of corrosion. As urbanization and industrialization continue to accelerate worldwide, the need for durable and long-lasting infrastructure becomes more pronounced. Anti-corrosion coatings play a pivotal role in this context, offering a cost-effective solution to extend the lifespan of steel structures and reduce maintenance costs. The market's expansion is driven by several factors, including technological advancements in coating formulations, increased awareness of the benefits of corrosion protection, and the growing emphasis on sustainable construction practices. As the market evolves, manufacturers are focusing on developing innovative coatings that offer enhanced performance and environmental benefits. This includes the use of water-based coatings, which have a lower environmental impact compared to traditional solvent-based coatings, and the incorporation of nanotechnology to improve the protective properties of coatings. The Global Anti-Corrosion Coating for Building Steel Structure Market is poised for continued growth as the demand for durable infrastructure and effective corrosion protection solutions increases.

| Report Metric | Details |

| Report Name | Anti-Corrosion Coating for Building Steel Structure Market |

| Accounted market size in year | US$ 6043 million |

| Forecasted market size in 2031 | US$ 8463 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BASF, DuPont, Evonik, Henkel, Solvay, Valspar, Berger Paints, Akzo Nobel, Sherwin Williams, Wacker Chemie, Nippon paint, PPG, Kansai Paints, Alumax Industrial, Aexcel Corporation, Hempel, Jotun, Chugoku Marine Paints, Arkema, RPM International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |