What is Global Plasma Spray Powder Market?

The Global Plasma Spray Powder Market is a specialized segment within the broader materials and coatings industry. Plasma spray powder is a key component used in the plasma spray process, a thermal spray coating technique that involves melting powder materials and spraying them onto a surface to create a coating. This process is widely used for its ability to produce high-quality, durable coatings that enhance the surface properties of various materials. The market for plasma spray powder is driven by its applications across diverse industries, including aerospace, automotive, healthcare, and electronics, where it is used to improve wear resistance, corrosion resistance, and thermal barriers. The demand for plasma spray powder is influenced by technological advancements, increasing industrialization, and the need for high-performance materials. As industries continue to seek innovative solutions for surface enhancement, the plasma spray powder market is expected to grow, offering opportunities for manufacturers and suppliers to develop new formulations and expand their product offerings. The market's growth is also supported by the rising adoption of plasma spray technology in emerging economies, where industrial sectors are rapidly expanding. Overall, the Global Plasma Spray Powder Market plays a crucial role in advancing material science and engineering, contributing to the development of more efficient and sustainable industrial processes.

Aluminum Oxide, Titanium Dioxide, Zirconia, Other in the Global Plasma Spray Powder Market:

Aluminum oxide, titanium dioxide, zirconia, and other materials are integral components of the Global Plasma Spray Powder Market, each offering unique properties and applications. Aluminum oxide, also known as alumina, is one of the most commonly used materials in plasma spray powders due to its excellent hardness, wear resistance, and thermal stability. It is often used in applications requiring high durability and resistance to abrasion, such as in the aerospace and automotive industries. Alumina coatings are also valued for their electrical insulation properties, making them suitable for electronic components. Titanium dioxide, on the other hand, is renowned for its high refractive index and optical properties. It is widely used in applications where reflective coatings are needed, such as in optical devices and certain medical instruments. Titanium dioxide coatings also offer excellent corrosion resistance, which is beneficial in harsh environmental conditions. Zirconia, or zirconium dioxide, is another critical material in the plasma spray powder market, known for its exceptional thermal barrier properties. It is commonly used in applications that require thermal insulation, such as in gas turbines and other high-temperature environments. Zirconia coatings help protect components from thermal shock and extend their operational life. Additionally, zirconia is used in the medical field for its biocompatibility, particularly in dental and orthopedic implants. Beyond these materials, the plasma spray powder market also includes other specialized powders tailored for specific applications. These may include carbides, nitrides, and various metal alloys, each offering distinct properties such as enhanced hardness, corrosion resistance, or electrical conductivity. The choice of material depends on the specific requirements of the application, including the operating environment, desired coating properties, and cost considerations. As industries continue to evolve and demand more advanced materials, the development of new plasma spray powders with tailored properties is expected to drive innovation in the market. Manufacturers are investing in research and development to create powders that meet the increasingly stringent performance criteria of modern applications. This includes the development of nanostructured powders, which offer improved coating characteristics due to their fine particle size and unique microstructures. The use of advanced manufacturing techniques, such as plasma spheroidization and agglomeration, is also contributing to the production of high-quality plasma spray powders with consistent properties. As a result, the Global Plasma Spray Powder Market is poised for continued growth, driven by the need for high-performance coatings in a wide range of industries.

Industry, Medical, Other in the Global Plasma Spray Powder Market:

The Global Plasma Spray Powder Market finds extensive usage across various sectors, including industry, medical, and other specialized areas. In the industrial sector, plasma spray powders are primarily used to enhance the surface properties of components, improving their wear resistance, corrosion resistance, and thermal stability. This is particularly important in industries such as aerospace, automotive, and energy, where components are subjected to extreme conditions and require durable coatings to extend their service life. For instance, in the aerospace industry, plasma spray coatings are applied to turbine blades, engine components, and landing gear to protect them from high temperatures and corrosive environments. Similarly, in the automotive industry, plasma spray powders are used to coat engine parts, exhaust systems, and brake components, enhancing their performance and longevity. In the medical field, plasma spray powders play a crucial role in the development of biocompatible coatings for implants and medical devices. Materials such as titanium dioxide and zirconia are commonly used to create coatings that promote osseointegration and improve the longevity of implants. These coatings are applied to orthopedic implants, dental implants, and other medical devices to enhance their compatibility with the human body and reduce the risk of rejection. The use of plasma spray technology in the medical sector is driven by the increasing demand for advanced materials that can meet the stringent requirements of medical applications. Beyond industry and medical applications, plasma spray powders are also used in other specialized areas, such as electronics, where they provide electrical insulation and thermal management solutions. In the electronics industry, plasma spray coatings are applied to circuit boards, connectors, and other components to protect them from environmental factors and improve their performance. Additionally, plasma spray powders are used in the production of decorative coatings, providing aesthetic finishes for consumer products and architectural applications. The versatility of plasma spray powders makes them suitable for a wide range of applications, and their usage is expected to grow as industries continue to seek innovative solutions for surface enhancement. The development of new plasma spray powders with tailored properties is also contributing to the expansion of the market, offering opportunities for manufacturers to cater to the evolving needs of different sectors. As a result, the Global Plasma Spray Powder Market is poised for continued growth, driven by the increasing demand for high-performance coatings across various industries.

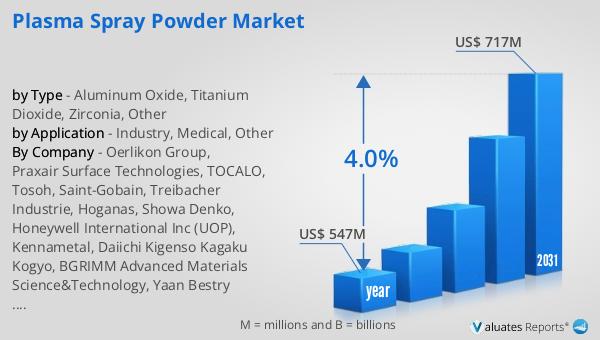

Global Plasma Spray Powder Market Outlook:

The global market for Plasma Spray Powder was valued at $547 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is projected to reach a revised size of $717 million, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period. This growth trajectory underscores the increasing demand for plasma spray powders across various industries, driven by the need for advanced materials that enhance the performance and durability of components. The market's expansion is supported by technological advancements in plasma spray technology, which have led to the development of new and improved powder formulations. These innovations are enabling manufacturers to produce coatings with superior properties, such as enhanced wear resistance, corrosion resistance, and thermal stability. As industries continue to evolve and face new challenges, the demand for high-performance coatings is expected to rise, further fueling the growth of the plasma spray powder market. Additionally, the increasing adoption of plasma spray technology in emerging economies is contributing to the market's expansion, as these regions experience rapid industrialization and infrastructure development. Overall, the Global Plasma Spray Powder Market is poised for continued growth, offering opportunities for manufacturers and suppliers to capitalize on the increasing demand for advanced materials and coatings.

| Report Metric | Details |

| Report Name | Plasma Spray Powder Market |

| Accounted market size in year | US$ 547 million |

| Forecasted market size in 2031 | US$ 717 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Oerlikon Group, Praxair Surface Technologies, TOCALO, Tosoh, Saint-Gobain, Treibacher Industrie, Hoganas, Showa Denko, Honeywell International Inc (UOP), Kennametal, Daiichi Kigenso Kagaku Kogyo, BGRIMM Advanced Materials Science&Technology, Yaan Bestry Performance Materials, CHALCO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |