What is Global Intelligent Pelletizing System Market?

The Global Intelligent Pelletizing System Market is a rapidly evolving sector that focuses on the development and deployment of advanced pelletizing systems. These systems are designed to enhance the efficiency and quality of pellet production across various industries. Intelligent pelletizing systems incorporate cutting-edge technologies such as automation, real-time monitoring, and data analytics to optimize the pelletizing process. This market is driven by the increasing demand for high-quality pellets in industries like plastics, rubber, chemicals, and food and pharmaceuticals. The systems are engineered to handle diverse materials, ensuring consistent pellet size and quality, which is crucial for downstream processing. As industries strive for greater efficiency and sustainability, the adoption of intelligent pelletizing systems is becoming more prevalent. These systems not only improve production rates but also reduce waste and energy consumption, aligning with global sustainability goals. The market is characterized by continuous innovation, with manufacturers investing in research and development to introduce more sophisticated and user-friendly systems. As a result, the Global Intelligent Pelletizing System Market is poised for significant growth, offering numerous opportunities for businesses to enhance their production capabilities and meet the evolving demands of their respective industries.

Plastic Pelletizing System, Rubber Pelletizing System in the Global Intelligent Pelletizing System Market:

In the realm of the Global Intelligent Pelletizing System Market, two prominent types of systems are the Plastic Pelletizing System and the Rubber Pelletizing System. The Plastic Pelletizing System is integral to the plastics industry, where it transforms raw plastic materials into uniform pellets. These pellets are then used in various applications, from packaging to automotive components. The system is designed to handle different types of plastics, including polyethylene, polypropylene, and PVC, ensuring that the pellets produced meet specific quality standards. Advanced features such as automated temperature control, pressure regulation, and real-time monitoring are incorporated to enhance the efficiency and precision of the pelletizing process. This not only improves the quality of the final product but also reduces operational costs and energy consumption. On the other hand, the Rubber Pelletizing System is tailored for the rubber industry, where it processes raw rubber materials into pellets that are used in the production of tires, seals, and other rubber products. The system is equipped with specialized components to handle the unique properties of rubber, such as its elasticity and viscosity. Intelligent controls and sensors are employed to maintain optimal processing conditions, ensuring that the pellets produced are of consistent size and quality. Both systems are designed to be flexible and adaptable, capable of handling a wide range of materials and production requirements. This versatility is crucial in today's dynamic market environment, where manufacturers must be able to quickly respond to changing customer demands and regulatory requirements. Moreover, the integration of intelligent technologies in these systems allows for greater automation and data-driven decision-making, enabling manufacturers to optimize their operations and improve overall productivity. As the demand for high-quality pellets continues to grow, the Plastic and Rubber Pelletizing Systems within the Global Intelligent Pelletizing System Market are expected to play a pivotal role in meeting the needs of various industries.

Plastics, Rubber Industry, Chemical Industry, Food & Pharmaceuticals in the Global Intelligent Pelletizing System Market:

The Global Intelligent Pelletizing System Market finds extensive applications across several key industries, including plastics, rubber, chemicals, and food and pharmaceuticals. In the plastics industry, intelligent pelletizing systems are used to convert raw plastic materials into uniform pellets, which are essential for producing a wide range of plastic products. These systems enhance the efficiency and precision of the pelletizing process, ensuring that the pellets meet specific quality standards. This is crucial for manufacturers who need to produce high-quality plastic products that meet stringent regulatory requirements. In the rubber industry, intelligent pelletizing systems are used to process raw rubber materials into pellets that are used in the production of tires, seals, and other rubber products. The systems are designed to handle the unique properties of rubber, such as its elasticity and viscosity, ensuring that the pellets produced are of consistent size and quality. This is important for manufacturers who need to produce high-performance rubber products that meet the demands of their customers. In the chemical industry, intelligent pelletizing systems are used to process a wide range of chemical materials into pellets that are used in various applications, from fertilizers to pharmaceuticals. The systems are equipped with advanced features such as automated temperature control and real-time monitoring, which enhance the efficiency and precision of the pelletizing process. This is crucial for manufacturers who need to produce high-quality chemical products that meet strict regulatory standards. In the food and pharmaceuticals industry, intelligent pelletizing systems are used to process raw materials into pellets that are used in the production of food and pharmaceutical products. The systems are designed to handle a wide range of materials, ensuring that the pellets produced meet specific quality standards. This is important for manufacturers who need to produce safe and effective products that meet the needs of their customers. Overall, the Global Intelligent Pelletizing System Market plays a vital role in enhancing the efficiency and quality of production processes across these key industries, enabling manufacturers to meet the evolving demands of their respective markets.

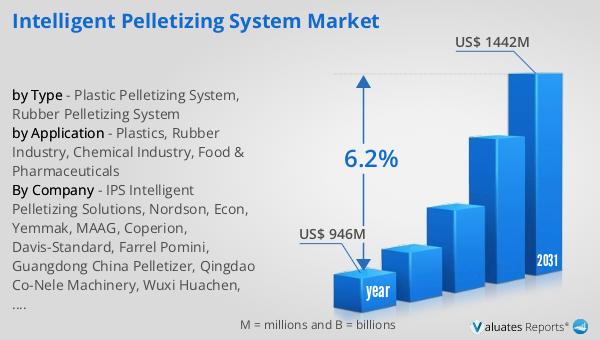

Global Intelligent Pelletizing System Market Outlook:

The outlook for the Global Intelligent Pelletizing System Market indicates a promising future, with the market valued at approximately $946 million in 2024. It is anticipated to expand to a revised size of $1,442 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% over the forecast period. This growth trajectory underscores the increasing demand for intelligent pelletizing systems across various industries. The market's expansion is driven by the need for more efficient and sustainable production processes, as well as the growing emphasis on quality and precision in pellet production. As industries continue to evolve and adapt to new challenges, the adoption of advanced technologies in pelletizing systems is becoming more prevalent. This trend is expected to drive further innovation and development in the market, offering new opportunities for businesses to enhance their production capabilities and meet the changing needs of their customers. The projected growth of the Global Intelligent Pelletizing System Market highlights the importance of these systems in modern manufacturing processes, as they enable companies to improve efficiency, reduce waste, and achieve greater sustainability. As a result, the market is poised for significant growth, providing a wealth of opportunities for businesses to capitalize on the benefits of intelligent pelletizing systems.

| Report Metric | Details |

| Report Name | Intelligent Pelletizing System Market |

| Accounted market size in year | US$ 946 million |

| Forecasted market size in 2031 | US$ 1442 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | IPS Intelligent Pelletizing Solutions, Nordson, Econ, Yemmak, MAAG, Coperion, Davis-Standard, Farrel Pomini, Guangdong China Pelletizer, Qingdao Co-Nele Machinery, Wuxi Huachen, Nanjing Juli Chemical Machinery, Nanjing Kerui Extrusion Machinery, Shanghai Chooshin Industrial, Jiangsu Useon Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |