What is Global Compact Medical Laser Market?

The Global Compact Medical Laser Market refers to the worldwide industry focused on the development, production, and distribution of compact medical lasers. These lasers are specialized devices used in various medical procedures, including surgeries, dermatological treatments, and ophthalmology. Compact medical lasers are valued for their precision, efficiency, and ability to minimize damage to surrounding tissues. They are designed to be smaller and more portable than traditional laser systems, making them ideal for use in diverse medical settings. The market encompasses a range of laser types, including CO2 lasers, fiber lasers, and others, each with specific applications and benefits. The growing demand for minimally invasive procedures, advancements in laser technology, and increasing healthcare expenditure are driving the expansion of this market. As medical professionals and patients alike seek more effective and less invasive treatment options, the Global Compact Medical Laser Market continues to evolve, offering innovative solutions that enhance patient outcomes and streamline medical practices.

CO2 Lasers, Fiber Lasers, Others in the Global Compact Medical Laser Market:

CO2 lasers, fiber lasers, and other types of lasers play a crucial role in the Global Compact Medical Laser Market, each offering unique advantages and applications. CO2 lasers are widely used in medical procedures due to their high precision and ability to cut, vaporize, or coagulate tissues with minimal damage to surrounding areas. These lasers operate at a wavelength that is highly absorbed by water, making them ideal for soft tissue surgeries, dermatological treatments, and gynecological procedures. CO2 lasers are particularly effective in removing skin lesions, warts, and scars, as well as in performing delicate surgeries such as vocal cord and laryngeal procedures. Fiber lasers, on the other hand, are known for their versatility and efficiency. They use optical fibers as the medium to generate laser beams, which can be easily directed to specific areas of the body. Fiber lasers are commonly used in endoscopic surgeries, where their flexibility and precision allow for minimally invasive procedures. They are also employed in dental treatments, ophthalmology, and aesthetic procedures such as hair removal and skin resurfacing. The compact size and high power output of fiber lasers make them suitable for a wide range of medical applications. Other types of lasers in the Global Compact Medical Laser Market include diode lasers, Nd:YAG lasers, and excimer lasers. Diode lasers are popular for their compactness, reliability, and cost-effectiveness. They are used in various medical fields, including dentistry, ophthalmology, and dermatology. Nd:YAG lasers, which operate at a longer wavelength, are effective in treating deeper tissues and are often used in vascular surgeries, tattoo removal, and certain types of cancer treatments. Excimer lasers, which emit ultraviolet light, are primarily used in ophthalmology for procedures such as LASIK eye surgery to correct vision problems. Each type of laser in the Global Compact Medical Laser Market offers distinct benefits and is chosen based on the specific needs of the medical procedure. The continuous advancements in laser technology, coupled with the increasing demand for minimally invasive treatments, are driving the growth and diversification of this market. As medical professionals seek more precise and efficient tools, the adoption of CO2 lasers, fiber lasers, and other laser types is expected to rise, further enhancing the capabilities of modern medical practices.

Hospital, Clinic, Others in the Global Compact Medical Laser Market:

The usage of compact medical lasers in hospitals, clinics, and other medical settings is transforming the landscape of modern healthcare. In hospitals, compact medical lasers are employed in a wide range of surgical procedures due to their precision and ability to minimize damage to surrounding tissues. Surgeons use these lasers for delicate operations such as neurosurgery, cardiovascular surgery, and orthopedic procedures. The high precision of lasers allows for targeted treatment, reducing the risk of complications and promoting faster recovery times for patients. Additionally, compact medical lasers are used in hospitals for various diagnostic purposes, including imaging and tissue analysis, enhancing the accuracy of diagnoses and treatment plans. In clinics, compact medical lasers are widely used for dermatological treatments, aesthetic procedures, and minor surgeries. Dermatologists utilize lasers for skin resurfacing, removal of skin lesions, and treatment of conditions such as acne scars, wrinkles, and pigmentation issues. The non-invasive nature of laser treatments makes them popular among patients seeking cosmetic enhancements with minimal downtime. Clinics also use compact medical lasers for dental procedures, including cavity preparation, gum surgeries, and teeth whitening. The precision and efficiency of lasers in dental treatments result in less pain and faster healing for patients. Beyond hospitals and clinics, compact medical lasers find applications in various other medical settings. For instance, they are used in ambulatory surgical centers for outpatient procedures, providing patients with convenient and efficient treatment options. Compact medical lasers are also employed in veterinary medicine for surgeries and treatments on animals, showcasing their versatility across different fields. Furthermore, research institutions and academic centers utilize these lasers for medical research and development, contributing to the advancement of medical science and technology. The adoption of compact medical lasers in these diverse settings is driven by the growing demand for minimally invasive procedures, improved patient outcomes, and advancements in laser technology. As healthcare providers continue to seek innovative solutions to enhance patient care, the usage of compact medical lasers is expected to expand, offering new possibilities for medical treatments and procedures.

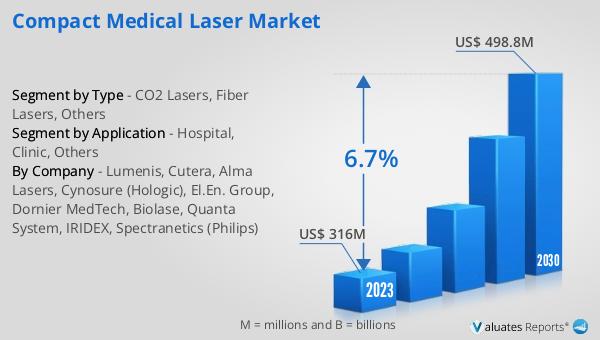

Global Compact Medical Laser Market Outlook:

The global Compact Medical Laser market was valued at US$ 316 million in 2023 and is anticipated to reach US$ 498.8 million by 2030, witnessing a CAGR of 6.7% during the forecast period 2024-2030. This market growth reflects the increasing demand for advanced medical laser technologies that offer precision, efficiency, and minimally invasive treatment options. The rising prevalence of chronic diseases, coupled with the growing aging population, is driving the need for innovative medical solutions that can improve patient outcomes and reduce recovery times. Additionally, the continuous advancements in laser technology, such as the development of more compact and portable laser systems, are contributing to the market's expansion. Healthcare providers are increasingly adopting compact medical lasers for a wide range of applications, including surgeries, dermatological treatments, and diagnostic procedures, due to their ability to deliver precise and effective results. As the market continues to evolve, the adoption of compact medical lasers is expected to rise, further enhancing the capabilities of modern medical practices and improving the quality of patient care.

| Report Metric | Details |

| Report Name | Compact Medical Laser Market |

| Accounted market size in 2023 | US$ 316 million |

| Forecasted market size in 2030 | US$ 498.8 million |

| CAGR | 6.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Lumenis, Cutera, Alma Lasers, Cynosure (Hologic), El.En. Group, Dornier MedTech, Biolase, Quanta System, IRIDEX, Spectranetics (Philips) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |