What is Global Fully Automatic Compressed Air Condensate Drain Market?

The Global Fully Automatic Compressed Air Condensate Drain Market refers to the industry focused on the production and distribution of devices that automatically remove condensate from compressed air systems. These systems are essential in various industries as they help maintain the efficiency and longevity of compressed air equipment by preventing water accumulation, which can cause corrosion and damage. Fully automatic condensate drains are designed to operate without manual intervention, ensuring continuous and reliable performance. They are equipped with sensors and control mechanisms that detect the presence of condensate and discharge it automatically. This market includes a range of products, from simple mechanical drains to advanced electronic models, catering to different industrial needs and applications. The demand for these devices is driven by the increasing adoption of compressed air systems across various sectors, including manufacturing, automotive, pharmaceuticals, and oil and gas, among others. As industries continue to seek ways to improve operational efficiency and reduce maintenance costs, the market for fully automatic compressed air condensate drains is expected to grow.

Mechanical, Electronic in the Global Fully Automatic Compressed Air Condensate Drain Market:

In the Global Fully Automatic Compressed Air Condensate Drain Market, there are primarily two types of technologies used: mechanical and electronic. Mechanical condensate drains operate based on physical principles and do not require any external power source. They typically use a float mechanism that rises and falls with the level of condensate in the drain. When the condensate reaches a certain level, the float triggers a valve to open, allowing the condensate to be discharged. These drains are simple, reliable, and cost-effective, making them suitable for a wide range of applications. However, they may not be as precise or efficient as electronic models, especially in environments with fluctuating condensate levels. On the other hand, electronic condensate drains use sensors and electronic controls to detect the presence of condensate and discharge it automatically. These drains are more sophisticated and can offer greater precision and efficiency. They often include features such as adjustable discharge intervals, alarm systems, and self-cleaning mechanisms. Electronic drains are ideal for applications where precise control over condensate removal is required, such as in high-end manufacturing processes or in environments with strict regulatory requirements. Despite their higher cost, the benefits of electronic drains, including reduced maintenance and downtime, often justify the investment. Both mechanical and electronic condensate drains play a crucial role in maintaining the efficiency and reliability of compressed air systems. The choice between the two depends on various factors, including the specific requirements of the application, budget constraints, and the level of automation desired. As industries continue to evolve and adopt more advanced technologies, the demand for both types of condensate drains is expected to grow, with electronic models likely to see a higher rate of adoption due to their superior performance and features.

Automobile Industry, Manufacturing, Pharmaceutical Industry, Oil and Gas, Aerospace, Mining Industry, Others in the Global Fully Automatic Compressed Air Condensate Drain Market:

The usage of Global Fully Automatic Compressed Air Condensate Drain Market spans across various industries, each benefiting from the efficiency and reliability these devices offer. In the automobile industry, these drains are crucial for maintaining the performance of pneumatic tools and equipment used in manufacturing and assembly lines. By ensuring that condensate is automatically removed, these drains help prevent corrosion and damage to equipment, leading to reduced maintenance costs and downtime. In the manufacturing sector, fully automatic condensate drains are used in a wide range of applications, from food and beverage production to electronics manufacturing. They help maintain the quality of compressed air, which is essential for the smooth operation of machinery and processes. In the pharmaceutical industry, where strict hygiene and quality standards are paramount, these drains play a vital role in ensuring that compressed air systems remain free of moisture and contaminants. This helps in maintaining the integrity of pharmaceutical products and processes. The oil and gas industry also relies heavily on fully automatic condensate drains to protect their equipment from the harmful effects of condensate accumulation. These drains are used in various stages of oil and gas production, from extraction to refining, ensuring that equipment operates efficiently and safely. In the aerospace industry, where precision and reliability are critical, fully automatic condensate drains help maintain the performance of pneumatic systems used in aircraft manufacturing and maintenance. The mining industry, with its harsh and demanding environments, also benefits from the use of these drains, which help protect equipment from the damaging effects of moisture and condensate. Other industries, such as textiles, chemicals, and power generation, also use fully automatic condensate drains to improve the efficiency and reliability of their compressed air systems. Overall, the widespread usage of these devices across various industries highlights their importance in maintaining the performance and longevity of compressed air systems.

Global Fully Automatic Compressed Air Condensate Drain Market Outlook:

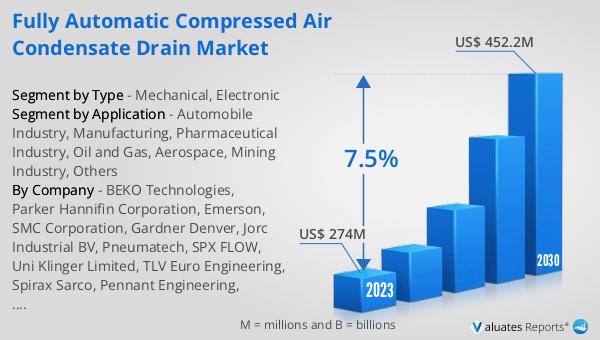

The global Fully Automatic Compressed Air Condensate Drain market was valued at US$ 274 million in 2023 and is anticipated to reach US$ 452.2 million by 2030, witnessing a CAGR of 7.5% during the forecast period 2024-2030. This market outlook indicates a significant growth trajectory, driven by the increasing adoption of compressed air systems across various industries. The rising demand for efficient and reliable condensate removal solutions is expected to fuel the growth of this market. As industries continue to seek ways to improve operational efficiency and reduce maintenance costs, the adoption of fully automatic condensate drains is likely to increase. The market is also expected to benefit from advancements in technology, leading to the development of more sophisticated and efficient condensate drain solutions. The growing awareness about the importance of maintaining the quality of compressed air and preventing equipment damage is also expected to drive the demand for these devices. Overall, the global Fully Automatic Compressed Air Condensate Drain market is poised for significant growth in the coming years, with a positive outlook for both manufacturers and end-users.

| Report Metric | Details |

| Report Name | Fully Automatic Compressed Air Condensate Drain Market |

| Accounted market size in 2023 | US$ 274 million |

| Forecasted market size in 2030 | US$ 452.2 million |

| CAGR | 7.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BEKO Technologies, Parker Hannifin Corporation, Emerson, SMC Corporation, Gardner Denver, Jorc Industrial BV, Pneumatech, SPX FLOW, Uni Klinger Limited, TLV Euro Engineering, Spirax Sarco, Pennant Engineering, MANKENBERG, INGERSOLL RAND, ENE SYSTEM, ARI-Armaturen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |