What is Global Automatic Feeding Screwdriver Machines Market?

The Global Automatic Feeding Screwdriver Machines Market refers to the industry that manufactures and sells machines designed to automatically feed and drive screws into various materials. These machines are widely used in manufacturing and assembly lines to enhance productivity and ensure precision. They are equipped with advanced technology to handle different types of screws and can be programmed to perform repetitive tasks with high accuracy. The market for these machines is growing due to the increasing demand for automation in various industries, including electronics, automotive, and consumer goods. Companies are investing in these machines to reduce labor costs, improve efficiency, and maintain consistent quality in their products. The market is characterized by continuous innovation, with manufacturers developing more sophisticated and user-friendly machines to meet the evolving needs of their customers.

Single Axis, Multi-Axis in the Global Automatic Feeding Screwdriver Machines Market:

Single Axis and Multi-Axis are two types of configurations in the Global Automatic Feeding Screwdriver Machines Market. Single Axis machines are designed to move in one direction, typically along a straight line. These machines are simpler in design and are often used for tasks that require linear motion, such as driving screws into a single row of holes. They are ideal for applications where the workpiece remains stationary, and the machine moves to perform the task. Single Axis machines are generally more affordable and easier to maintain, making them a popular choice for small to medium-sized enterprises. On the other hand, Multi-Axis machines are more complex and can move in multiple directions, including up and down, left and right, and rotational movements. These machines are capable of performing more intricate tasks and can handle workpieces with complex geometries. Multi-Axis machines are often used in industries that require high precision and flexibility, such as aerospace, automotive, and electronics. They are equipped with advanced control systems and sensors to ensure accurate positioning and consistent performance. The choice between Single Axis and Multi-Axis machines depends on the specific requirements of the application, including the complexity of the task, the size of the workpiece, and the desired level of automation. Both types of machines offer significant benefits in terms of efficiency, accuracy, and productivity, but Multi-Axis machines provide greater versatility and can handle a wider range of tasks. As the demand for automation continues to grow, manufacturers are developing more advanced Single Axis and Multi-Axis machines to meet the diverse needs of their customers. These machines are designed to be user-friendly, with intuitive interfaces and easy-to-use programming features. They are also built to be durable and reliable, with robust construction and high-quality components to ensure long-term performance. In addition to their technical capabilities, Single Axis and Multi-Axis machines are also designed with safety in mind. They are equipped with safety features such as emergency stop buttons, protective guards, and sensors to detect any potential hazards. This ensures that operators can work safely and efficiently, without the risk of injury. Overall, Single Axis and Multi-Axis machines play a crucial role in the Global Automatic Feeding Screwdriver Machines Market, offering a range of solutions to meet the diverse needs of different industries.

Industrial, Construction Industry, Semiconductor Industry, Medical Device Industry, Others in the Global Automatic Feeding Screwdriver Machines Market:

The Global Automatic Feeding Screwdriver Machines Market finds extensive usage across various industries, including Industrial, Construction, Semiconductor, Medical Device, and others. In the Industrial sector, these machines are used to automate the assembly processes, enhancing productivity and ensuring precision. They are particularly useful in the manufacturing of electronic devices, automotive components, and consumer goods, where consistent quality and high-speed production are critical. The machines help in reducing labor costs and minimizing human errors, leading to improved efficiency and product quality. In the Construction Industry, automatic feeding screwdriver machines are used for tasks such as fastening drywall, assembling prefabricated structures, and installing fixtures. These machines enable faster and more accurate screw driving, which is essential for maintaining the structural integrity of buildings and other constructions. They also reduce the physical strain on workers, making the construction process safer and more efficient. In the Semiconductor Industry, these machines are used for assembling delicate components with high precision. The semiconductor manufacturing process requires the handling of tiny screws and components, which can be challenging and time-consuming if done manually. Automatic feeding screwdriver machines ensure that these tasks are performed with high accuracy, reducing the risk of damage to sensitive components and improving overall production efficiency. In the Medical Device Industry, the machines are used for assembling medical equipment and devices, such as surgical instruments, diagnostic tools, and implants. The precision and reliability of these machines are crucial in ensuring that medical devices meet stringent quality standards and function correctly. They help in maintaining consistency in the assembly process, which is vital for the safety and effectiveness of medical devices. Apart from these industries, automatic feeding screwdriver machines are also used in various other sectors, such as aerospace, furniture manufacturing, and home appliances. In the aerospace industry, they are used for assembling aircraft components, where precision and reliability are of utmost importance. In furniture manufacturing, these machines help in speeding up the assembly process and ensuring that the final products are sturdy and well-constructed. In the home appliances sector, they are used for assembling products such as refrigerators, washing machines, and air conditioners, where consistent quality and efficient production are essential. Overall, the Global Automatic Feeding Screwdriver Machines Market plays a vital role in enhancing productivity, ensuring precision, and improving efficiency across various industries.

Global Automatic Feeding Screwdriver Machines Market Outlook:

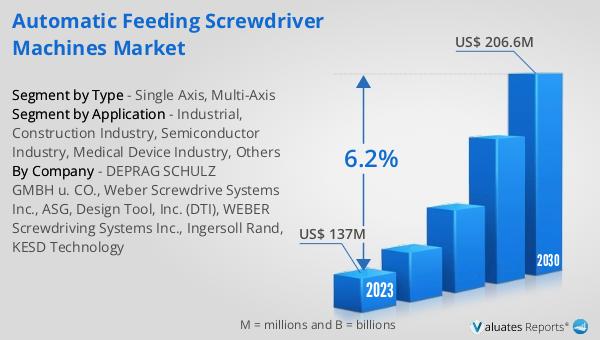

The global market for Automatic Feeding Screwdriver Machines was valued at $137 million in 2023 and is projected to reach $206.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.2% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for automation in various industries, including electronics, automotive, and consumer goods. Companies are investing in these machines to reduce labor costs, improve efficiency, and maintain consistent quality in their products. The market is characterized by continuous innovation, with manufacturers developing more sophisticated and user-friendly machines to meet the evolving needs of their customers. The adoption of advanced technologies, such as artificial intelligence and machine learning, is also contributing to the growth of the market. These technologies enable the machines to perform complex tasks with high precision and efficiency, further enhancing their appeal to various industries. Additionally, the growing focus on sustainability and energy efficiency is driving the demand for eco-friendly and energy-efficient automatic feeding screwdriver machines. Manufacturers are developing machines that consume less power and produce fewer emissions, aligning with the global trend towards sustainable manufacturing practices. The market is also witnessing increased competition, with new players entering the market and existing players expanding their product portfolios. This is leading to the development of more advanced and cost-effective machines, providing customers with a wider range of options to choose from. Overall, the global market for Automatic Feeding Screwdriver Machines is expected to continue its growth trajectory, driven by the increasing demand for automation, technological advancements, and the focus on sustainability.

| Report Metric | Details |

| Report Name | Automatic Feeding Screwdriver Machines Market |

| Accounted market size in 2023 | US$ 137 million |

| Forecasted market size in 2030 | US$ 206.6 million |

| CAGR | 6.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DEPRAG SCHULZ GMBH u. CO., Weber Screwdrive Systems Inc., ASG, Design Tool, Inc. (DTI), WEBER Screwdriving Systems Inc., Ingersoll Rand, KESD Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |