What is Global Food Industry Decanter Centrifuge Market?

The global food industry decanter centrifuge market is a specialized segment within the broader food processing equipment industry. Decanter centrifuges are essential machines used to separate solid particles from liquids in various food processing applications. These centrifuges operate on the principle of centrifugal force, which allows for the efficient separation of components based on their density differences. The market for decanter centrifuges in the food industry is driven by the increasing demand for high-quality, safe, and hygienic food products. These machines are widely used in the processing of fruits and vegetables, edible oils, dairy products, and other food items to ensure the removal of impurities and enhance product quality. The market is characterized by technological advancements, with manufacturers continuously innovating to improve the efficiency, reliability, and ease of operation of decanter centrifuges. Additionally, the growing emphasis on sustainability and waste reduction in the food industry has further boosted the adoption of decanter centrifuges, as they help in minimizing waste and recovering valuable by-products. Overall, the global food industry decanter centrifuge market plays a crucial role in ensuring the production of high-quality food products while adhering to stringent safety and hygiene standards.

Two-Phase, Three-Phase in the Global Food Industry Decanter Centrifuge Market:

In the context of the global food industry decanter centrifuge market, two-phase and three-phase decanter centrifuges are the primary types of machines used for separation processes. Two-phase decanter centrifuges are designed to separate solid particles from liquids, resulting in a clarified liquid and a concentrated solid phase. These centrifuges are commonly used in applications where the primary goal is to remove solid impurities from a liquid stream, such as in fruit and vegetable processing, where pulp and other solid residues need to be separated from juices. The two-phase decanter centrifuge operates by feeding the mixture into a rotating bowl, where centrifugal force causes the denser solid particles to settle against the bowl wall, while the clarified liquid is discharged from the opposite end. This type of centrifuge is highly efficient in handling large volumes of material and is known for its robustness and reliability. On the other hand, three-phase decanter centrifuges are designed to separate a mixture into three distinct phases: a solid phase, a light liquid phase, and a heavy liquid phase. This type of centrifuge is particularly useful in applications where the separation of two immiscible liquids, along with solid particles, is required. For instance, in edible oil production, three-phase decanter centrifuges are used to separate oil, water, and solid residues from the raw material. The process involves feeding the mixture into the centrifuge, where the centrifugal force causes the solid particles to settle against the bowl wall, while the two liquid phases separate based on their density differences. The light liquid phase, typically oil, is discharged from one outlet, while the heavier liquid phase, usually water, is discharged from another outlet. The solid phase is collected separately. Three-phase decanter centrifuges are highly efficient in achieving precise separation and are widely used in industries where the recovery of valuable liquids is essential. Both two-phase and three-phase decanter centrifuges offer significant advantages in terms of efficiency, reliability, and ease of operation. They are designed to handle a wide range of feed materials, including those with high solid content, and can operate continuously, making them suitable for large-scale industrial applications. The choice between a two-phase and a three-phase decanter centrifuge depends on the specific requirements of the application, such as the nature of the feed material, the desired separation outcome, and the need for recovering multiple liquid phases. In the global food industry, the adoption of these centrifuges is driven by the need to improve product quality, enhance process efficiency, and comply with stringent regulatory standards. As the demand for high-quality, safe, and hygienic food products continues to grow, the role of two-phase and three-phase decanter centrifuges in the food processing industry is expected to become increasingly important.

Fruit and Vegetable Processing, Edible Oil Production, Dairy Processing, Others in the Global Food Industry Decanter Centrifuge Market:

The global food industry decanter centrifuge market finds extensive usage in various areas, including fruit and vegetable processing, edible oil production, dairy processing, and other food processing applications. In fruit and vegetable processing, decanter centrifuges are used to separate solid residues, such as pulp, seeds, and skins, from juices and purees. This ensures that the final product is free from impurities and has a smooth texture. The use of decanter centrifuges in this area helps in improving the quality and shelf life of fruit and vegetable products, making them more appealing to consumers. Additionally, these centrifuges are used in the production of fruit concentrates and purees, where the removal of excess water and solid particles is crucial for achieving the desired consistency and flavor. In edible oil production, decanter centrifuges play a vital role in the extraction and purification of oils from various raw materials, such as seeds, nuts, and fruits. The centrifuges are used to separate oil, water, and solid residues, ensuring that the final product is pure and free from contaminants. This is particularly important in the production of high-quality edible oils, such as olive oil, where the presence of impurities can affect the taste, aroma, and shelf life of the product. Decanter centrifuges are also used in the refining process, where they help in removing impurities and unwanted components, such as free fatty acids and phospholipids, from the crude oil. This results in a higher quality and more stable oil that meets the stringent standards of the food industry. In dairy processing, decanter centrifuges are used to separate cream from milk, as well as to clarify whey and other dairy by-products. The separation of cream from milk is a critical step in the production of various dairy products, such as butter, cheese, and yogurt. Decanter centrifuges ensure that the cream is efficiently separated from the milk, resulting in a high-quality product with the desired fat content. Additionally, these centrifuges are used to clarify whey, which is a by-product of cheese production. The removal of solid particles from whey is essential for producing whey protein concentrates and isolates, which are widely used in the food and beverage industry as nutritional supplements and functional ingredients. Apart from fruit and vegetable processing, edible oil production, and dairy processing, decanter centrifuges are also used in other food processing applications, such as the production of beverages, meat and poultry processing, and the treatment of food waste. In beverage production, decanter centrifuges are used to clarify juices, wines, and beers, ensuring that the final product is clear and free from solid particles. In meat and poultry processing, these centrifuges are used to separate fat, water, and solid residues from meat products, resulting in a higher quality and more appealing product. Additionally, decanter centrifuges are used in the treatment of food waste, where they help in separating solid and liquid components, reducing the volume of waste, and recovering valuable by-products that can be used in animal feed or other applications. Overall, the use of decanter centrifuges in the global food industry is essential for ensuring the production of high-quality, safe, and hygienic food products, while also improving process efficiency and sustainability.

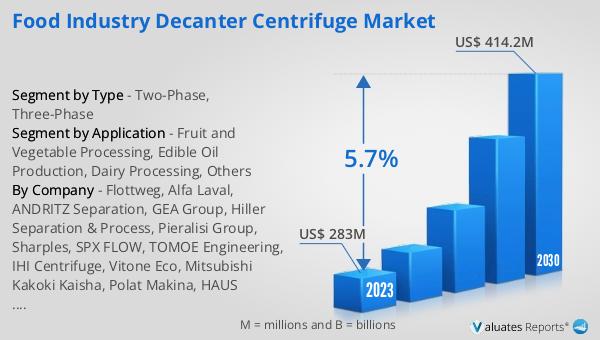

Global Food Industry Decanter Centrifuge Market Outlook:

The global food industry decanter centrifuge market was valued at $283 million in 2023 and is projected to grow to $414.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality, safe, and hygienic food products, as well as the need for efficient and reliable food processing equipment. Decanter centrifuges play a crucial role in various food processing applications, including fruit and vegetable processing, edible oil production, dairy processing, and other food processing areas. The market is characterized by technological advancements, with manufacturers continuously innovating to improve the efficiency, reliability, and ease of operation of decanter centrifuges. Additionally, the growing emphasis on sustainability and waste reduction in the food industry has further boosted the adoption of decanter centrifuges, as they help in minimizing waste and recovering valuable by-products. Overall, the global food industry decanter centrifuge market is expected to witness significant growth in the coming years, driven by the increasing demand for high-quality food products and the need for efficient and reliable food processing equipment.

| Report Metric | Details |

| Report Name | Food Industry Decanter Centrifuge Market |

| Accounted market size in 2023 | US$ 283 million |

| Forecasted market size in 2030 | US$ 414.2 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Flottweg, Alfa Laval, ANDRITZ Separation, GEA Group, Hiller Separation & Process, Pieralisi Group, Sharples, SPX FLOW, TOMOE Engineering, IHI Centrifuge, Vitone Eco, Mitsubishi Kakoki Kaisha, Polat Makina, HAUS Centrifuge Technologies, Centrisys, Gtech, Sanborn Technologies, SIEBTECHNIK TEMA, Thomas Broadbent & Sons, Noxon, Tsukishima Kikai, Amenduni, Gennaretti (Getech S.r.l.), SCI (Shanghai Centrifuge Institute), Nanjing Zhongchuan, Wuxi Zhongda Centrifugal Machinery, Haishen Machinery & Electric, Hebei GN Solids Control, Chongqing Jiangbei Machinery, FLSmidth |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |