What is Global Partial-Height Platform Screen Door Market?

The Global Partial-Height Platform Screen Door Market refers to the industry focused on the production and installation of screen doors that are installed on train platforms but do not extend to the full height of the platform. These doors are designed to enhance passenger safety by preventing accidental falls onto the tracks, while also improving the efficiency of train operations by managing passenger flow. Unlike full-height platform screen doors, partial-height doors are typically more cost-effective and easier to install, making them a popular choice for many transit systems around the world. They are commonly used in various types of rail systems, including subways, light rail, and commuter trains. The market for these doors is driven by the increasing demand for improved safety measures in public transportation, as well as the need for efficient crowd management solutions. As urban populations continue to grow and public transportation systems expand, the demand for partial-height platform screen doors is expected to rise.

Fixed Panel, Sliding Panel, Revolving Door in the Global Partial-Height Platform Screen Door Market:

In the Global Partial-Height Platform Screen Door Market, there are several types of doors, including fixed panels, sliding panels, and revolving doors. Fixed panels are stationary and do not move, providing a permanent barrier between the platform and the tracks. These are often used in areas where space is limited or where there is a need for a simple, low-maintenance solution. Sliding panels, on the other hand, are designed to open and close automatically in sync with the arrival and departure of trains. These doors are typically equipped with sensors and control systems that ensure they operate smoothly and safely. Sliding panels are popular in busy transit systems where efficient passenger flow is crucial. Revolving doors, although less common in the context of platform screen doors, offer a unique solution for managing passenger movement. These doors rotate around a central axis, allowing passengers to enter and exit the platform area in a controlled manner. Each type of door has its own advantages and is chosen based on the specific needs and constraints of the transit system. For example, fixed panels are often preferred in older stations where retrofitting with more complex systems might be challenging, while sliding panels are ideal for modern, high-traffic stations that require quick and efficient passenger movement. Revolving doors, though not widely used, can be beneficial in situations where space is at a premium and there is a need to control the direction of passenger flow. The choice of door type also depends on factors such as cost, maintenance requirements, and the overall design of the station. In summary, the Global Partial-Height Platform Screen Door Market offers a range of solutions to meet the diverse needs of public transportation systems, with each type of door providing unique benefits and addressing specific challenges.

Train, Rapid Transit, People Mover Station, Others in the Global Partial-Height Platform Screen Door Market:

The usage of Global Partial-Height Platform Screen Door Market solutions spans various areas, including trains, rapid transit systems, people mover stations, and other applications. In train stations, these doors play a crucial role in enhancing passenger safety by preventing accidental falls onto the tracks and reducing the risk of accidents. They also help in managing the flow of passengers, ensuring that boarding and alighting are done in an orderly manner. In rapid transit systems, such as subways and metro lines, partial-height platform screen doors are essential for maintaining efficient operations. These systems often experience high passenger volumes, and the doors help in reducing congestion on the platforms, improving overall service reliability. People mover stations, commonly found in airports and large commercial complexes, also benefit from the installation of partial-height platform screen doors. These doors ensure that passengers can move safely and efficiently between different areas, reducing the risk of accidents and improving the overall passenger experience. Other applications of these doors include light rail systems, monorails, and even some bus rapid transit systems. In all these areas, the primary goal of installing partial-height platform screen doors is to enhance safety, improve operational efficiency, and provide a better experience for passengers. The versatility of these doors makes them suitable for a wide range of public transportation systems, and their benefits are increasingly being recognized by transit authorities around the world.

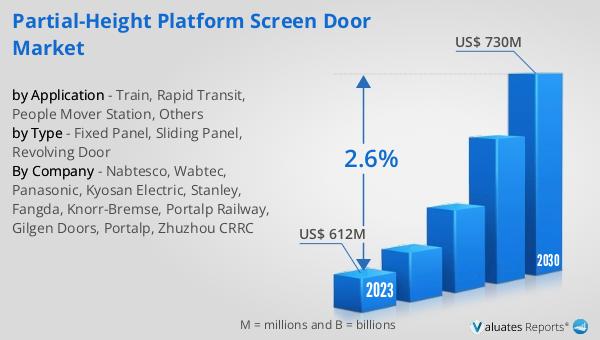

Global Partial-Height Platform Screen Door Market Outlook:

The global Partial-Height Platform Screen Door market was valued at US$ 612 million in 2023 and is anticipated to reach US$ 730 million by 2030, witnessing a CAGR of 2.6% during the forecast period from 2024 to 2030. This market growth reflects the increasing demand for safety and efficiency in public transportation systems worldwide. As urban populations continue to grow and more people rely on public transit for their daily commutes, the need for effective crowd management and safety solutions becomes more critical. Partial-height platform screen doors offer a cost-effective and practical solution to these challenges, making them an attractive option for transit authorities. The steady growth in this market is also driven by advancements in technology, which have made these doors more reliable and easier to maintain. Additionally, the increasing focus on sustainability and energy efficiency in public transportation systems is contributing to the adoption of partial-height platform screen doors, as they help in reducing energy consumption by improving the efficiency of train operations. Overall, the market outlook for partial-height platform screen doors is positive, with steady growth expected over the coming years.

| Report Metric | Details |

| Report Name | Partial-Height Platform Screen Door Market |

| Accounted market size in 2023 | US$ 612 million |

| Forecasted market size in 2030 | US$ 730 million |

| CAGR | 2.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nabtesco, Wabtec, Panasonic, Kyosan Electric, Stanley, Fangda, Knorr-Bremse, Portalp Railway, Gilgen Doors, Portalp, Zhuzhou CRRC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |