What is Global Inorganic Warm Box Binder Market?

The Global Inorganic Warm Box Binder Market is a specialized segment within the broader foundry industry, focusing on the production and application of binders used in the casting process. These binders are crucial in creating molds and cores that shape molten metal into desired forms. Unlike organic binders, inorganic warm box binders are known for their environmental benefits, as they emit fewer volatile organic compounds (VOCs) during the casting process. This makes them a more sustainable choice for foundries looking to reduce their environmental footprint. The market for these binders is driven by the increasing demand for high-quality castings in various industries, including automotive, aerospace, and construction. As industries strive for more efficient and eco-friendly production methods, the adoption of inorganic warm box binders is expected to grow. These binders offer advantages such as improved casting quality, reduced emissions, and enhanced worker safety, making them an attractive option for modern foundries. The market is characterized by continuous innovation, with manufacturers developing new formulations to meet the evolving needs of the industry. Overall, the Global Inorganic Warm Box Binder Market plays a vital role in advancing sustainable practices within the foundry sector.

Liquid, Powder in the Global Inorganic Warm Box Binder Market:

In the Global Inorganic Warm Box Binder Market, two primary forms of binders are prevalent: liquid and powder. Each form has its unique characteristics and applications, catering to different needs within the foundry industry. Liquid inorganic warm box binders are typically composed of water-soluble inorganic salts and are known for their ease of use and quick curing times. These binders are often preferred in applications where rapid production cycles are essential, as they allow for faster mold and core production. The liquid form also offers excellent flowability, ensuring that the binder can easily penetrate and coat the sand particles used in mold making. This results in strong, durable molds that can withstand the rigors of the casting process. Additionally, liquid binders are often favored for their ability to produce castings with smooth surfaces and fine details, making them ideal for intricate designs and high-precision applications. On the other hand, powder inorganic warm box binders are typically composed of finely ground inorganic compounds that are mixed with sand to form the mold or core. These binders are known for their versatility and can be tailored to meet specific casting requirements. Powder binders offer the advantage of being easily stored and transported, as they are less prone to spillage and contamination compared to their liquid counterparts. They also provide foundries with greater control over the binder-to-sand ratio, allowing for precise adjustments to achieve the desired mold properties. This flexibility makes powder binders suitable for a wide range of casting applications, from large-scale industrial components to small, intricate parts. Furthermore, powder binders are often chosen for their ability to produce castings with excellent dimensional stability and reduced defects, ensuring high-quality end products. Both liquid and powder inorganic warm box binders contribute to the overall efficiency and sustainability of the casting process. By reducing emissions and improving casting quality, these binders help foundries meet stringent environmental regulations while maintaining competitive production standards. As the demand for high-performance castings continues to rise, the Global Inorganic Warm Box Binder Market is expected to see increased adoption of both liquid and powder binders, each offering unique benefits to the foundry industry.

Aluminum Castings, Iron Castings in the Global Inorganic Warm Box Binder Market:

The Global Inorganic Warm Box Binder Market finds significant applications in the production of aluminum and iron castings, two of the most widely used materials in various industries. In the realm of aluminum castings, inorganic warm box binders play a crucial role in creating lightweight, durable components that are essential for automotive, aerospace, and consumer electronics applications. Aluminum castings require molds and cores that can withstand high temperatures and pressures during the casting process, and inorganic warm box binders provide the necessary strength and stability. These binders help produce castings with smooth surfaces and precise dimensions, ensuring that the final products meet stringent quality standards. The use of inorganic binders also reduces the risk of gas defects and improves the overall integrity of the castings, making them suitable for critical applications where performance and reliability are paramount. In the production of iron castings, inorganic warm box binders offer similar benefits, enhancing the quality and efficiency of the casting process. Iron castings are widely used in industries such as construction, machinery, and transportation, where strength and durability are key requirements. Inorganic binders help create molds and cores that can withstand the high temperatures and mechanical stresses associated with iron casting, resulting in components that are robust and long-lasting. The use of inorganic binders also contributes to a cleaner casting environment, as they emit fewer pollutants compared to traditional organic binders. This aligns with the growing emphasis on sustainability and environmental responsibility within the foundry industry. By reducing emissions and minimizing waste, inorganic warm box binders help foundries meet regulatory requirements and improve their overall environmental performance. The versatility of inorganic warm box binders makes them suitable for a wide range of casting applications, from large-scale industrial components to intricate, high-precision parts. As industries continue to demand high-quality castings with improved performance characteristics, the Global Inorganic Warm Box Binder Market is poised to play a vital role in meeting these needs. By offering a sustainable and efficient solution for aluminum and iron casting production, inorganic warm box binders contribute to the advancement of modern manufacturing practices and the development of innovative products across various sectors.

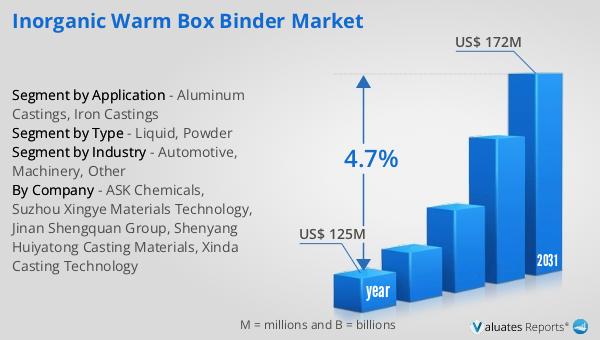

Global Inorganic Warm Box Binder Market Outlook:

In 2024, the global market for Inorganic Warm Box Binder was valued at approximately $125 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of $172 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.7% over the forecast period. The steady increase in market size reflects the rising demand for environmentally friendly and efficient casting solutions across various industries. As more foundries and manufacturers seek to adopt sustainable practices, the appeal of inorganic warm box binders continues to grow. These binders offer significant advantages, such as reduced emissions and improved casting quality, which align with the industry's evolving needs. The projected growth in the market underscores the importance of innovation and adaptation in the foundry sector, as companies strive to meet the demands of modern manufacturing while minimizing their environmental impact. The increasing adoption of inorganic warm box binders is a testament to their effectiveness in enhancing the casting process and delivering high-quality results. As the market evolves, it is expected to see further advancements in binder formulations and applications, driving continued growth and development in the Global Inorganic Warm Box Binder Market.

| Report Metric | Details |

| Report Name | Inorganic Warm Box Binder Market |

| Accounted market size in year | US$ 125 million |

| Forecasted market size in 2031 | US$ 172 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Industry |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASK Chemicals, Suzhou Xingye Materials Technology, Jinan Shengquan Group, Shenyang Huiyatong Casting Materials, Xinda Casting Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |