What is Global Fixed Hydrogen Sulfide Gas Detector Market?

The Global Fixed Hydrogen Sulfide Gas Detector Market refers to the industry focused on the production and distribution of devices designed to detect hydrogen sulfide (H2S) gas in fixed locations. Hydrogen sulfide is a colorless gas known for its distinctive rotten egg smell, and it is highly toxic and flammable. These detectors are crucial in various industries to ensure safety and prevent hazardous exposure to H2S, which can be lethal even at low concentrations. The market encompasses a range of technologies and products that are installed in specific locations to continuously monitor the presence of hydrogen sulfide gas. These detectors are essential in environments where H2S is likely to be present, such as oil and gas facilities, wastewater treatment plants, chemical manufacturing sites, and other industrial settings. The market is driven by the need for safety regulations and the increasing awareness of the dangers associated with hydrogen sulfide exposure. As industries continue to prioritize safety and compliance, the demand for reliable and efficient fixed hydrogen sulfide gas detectors is expected to grow. These devices play a critical role in protecting workers and the environment from the harmful effects of hydrogen sulfide gas.

Electrochemical, Catalytic Combustion (CAT), Infrared (IR), Photoionization (PID), Semiconductor Oxide in the Global Fixed Hydrogen Sulfide Gas Detector Market:

The Global Fixed Hydrogen Sulfide Gas Detector Market utilizes various technologies to detect the presence of hydrogen sulfide gas, each with its unique advantages and applications. Electrochemical sensors are among the most common types used in these detectors. They operate by oxidizing or reducing the target gas at an electrode, producing a current that is proportional to the gas concentration. This method is highly sensitive and specific to hydrogen sulfide, making it ideal for environments where precise detection is crucial. Electrochemical sensors are often favored for their accuracy and reliability, although they may require regular calibration and maintenance to ensure optimal performance. Catalytic Combustion (CAT) sensors, on the other hand, detect hydrogen sulfide by measuring the heat produced during the combustion of the gas. These sensors are robust and can operate in harsh conditions, making them suitable for industrial settings. However, they may not be as selective as electrochemical sensors and can be affected by the presence of other combustible gases. Infrared (IR) sensors detect hydrogen sulfide by measuring the absorption of infrared light by the gas. This non-contact method is highly reliable and can provide continuous monitoring without the need for frequent calibration. IR sensors are particularly useful in environments where other gases may interfere with detection, as they are less prone to cross-sensitivity. Photoionization Detectors (PID) use ultraviolet light to ionize gas molecules, measuring the resulting current to determine gas concentration. While PIDs are more commonly used for volatile organic compounds, they can be adapted for hydrogen sulfide detection. They offer fast response times and are effective in detecting low concentrations of gas. Semiconductor Oxide sensors detect hydrogen sulfide by measuring changes in electrical resistance as the gas interacts with a metal oxide surface. These sensors are cost-effective and can be used in a variety of applications, although they may be less sensitive than other types. Each of these technologies offers distinct benefits, and the choice of sensor often depends on the specific requirements of the application, such as sensitivity, selectivity, and environmental conditions. The diversity of technologies available in the Global Fixed Hydrogen Sulfide Gas Detector Market ensures that industries can select the most appropriate solution to meet their safety and operational needs.

Oil & Gas, Wastewater Treatment, Chemical Industry, Mining & Metallurgy, Food Processing, Laboratories, Other in the Global Fixed Hydrogen Sulfide Gas Detector Market:

The Global Fixed Hydrogen Sulfide Gas Detector Market finds extensive application across various industries, each with unique requirements for safety and gas detection. In the oil and gas sector, these detectors are indispensable due to the high risk of hydrogen sulfide exposure during drilling, extraction, and refining processes. Fixed detectors are strategically placed in areas where H2S is likely to accumulate, providing continuous monitoring to protect workers and prevent accidents. In wastewater treatment facilities, hydrogen sulfide is a common byproduct of the decomposition of organic matter. Fixed gas detectors are used to monitor H2S levels in treatment tanks, sludge processing areas, and other critical points to ensure safe working conditions and compliance with environmental regulations. The chemical industry also relies heavily on fixed hydrogen sulfide gas detectors, as H2S is often used or produced in various chemical reactions. These detectors help maintain a safe environment by providing early warning of gas leaks or accumulation, allowing for timely intervention. In mining and metallurgy, hydrogen sulfide can be released during the extraction and processing of certain ores. Fixed detectors are essential for monitoring air quality in mines and processing plants, safeguarding workers from potential exposure. The food processing industry may encounter hydrogen sulfide in certain fermentation processes or as a result of bacterial activity. Fixed gas detectors help ensure that H2S levels remain within safe limits, protecting both workers and product quality. Laboratories, particularly those involved in research or testing of sulfur compounds, also benefit from fixed hydrogen sulfide gas detectors. These devices provide a critical layer of safety, allowing researchers to focus on their work without the risk of exposure. Other industries, such as pulp and paper, agriculture, and pharmaceuticals, may also require fixed hydrogen sulfide gas detectors to address specific safety concerns related to H2S. The versatility and reliability of these detectors make them an essential component of safety protocols across a wide range of applications. By providing continuous monitoring and early warning of hydrogen sulfide presence, fixed gas detectors play a vital role in protecting workers, ensuring regulatory compliance, and maintaining safe operational environments.

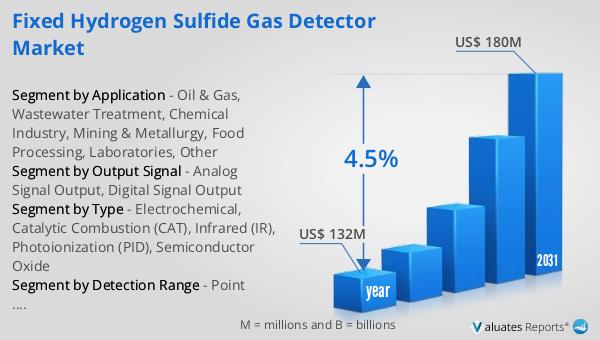

Global Fixed Hydrogen Sulfide Gas Detector Market Outlook:

In 2024, the global market for Fixed Hydrogen Sulfide Gas Detectors was valued at approximately $132 million. This market is anticipated to experience growth over the coming years, with projections indicating that it will reach a revised size of around $180 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.5% during the forecast period. The increasing demand for these detectors is driven by the need for enhanced safety measures in industries where hydrogen sulfide gas is prevalent. As awareness of the dangers associated with hydrogen sulfide exposure continues to rise, industries are investing in reliable detection systems to protect workers and comply with safety regulations. The market's expansion is also supported by technological advancements in gas detection technologies, which offer improved sensitivity, accuracy, and reliability. These advancements enable industries to implement more effective monitoring solutions, reducing the risk of accidents and ensuring a safer working environment. The projected growth of the Global Fixed Hydrogen Sulfide Gas Detector Market reflects the ongoing commitment of industries to prioritize safety and environmental protection. As the market continues to evolve, it is expected to play a crucial role in safeguarding workers and communities from the hazards of hydrogen sulfide gas.

| Report Metric | Details |

| Report Name | Fixed Hydrogen Sulfide Gas Detector Market |

| Accounted market size in year | US$ 132 million |

| Forecasted market size in 2031 | US$ 180 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Sampling Method |

|

| Segment by Output Signal |

|

| Segment by Detection Range |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BEBUR, Dräger, GasDog, Honeywell, Industrial Scientific, RKI Instruments, Shenzhen Eranntex Electronics, Beijing Collihigh Sensing Technology, SHENZHEN YUANTE TECHNOLOGY, Shenzhen Rui 'an Environmental Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |