What is Global Humanoid Robotic Cycloidal Gearboxes Market?

The Global Humanoid Robotic Cycloidal Gearboxes Market is a specialized segment within the broader robotics industry, focusing on the development and application of cycloidal gearboxes in humanoid robots. Cycloidal gearboxes are crucial components that enable precise and efficient motion control in robotic systems. These gearboxes are designed to handle high torque and provide smooth, accurate movements, which are essential for the complex tasks performed by humanoid robots. The market is driven by the increasing demand for advanced robotics in various sectors, including healthcare, manufacturing, and entertainment. As humanoid robots become more sophisticated, the need for reliable and efficient gear systems like cycloidal gearboxes grows. These gearboxes are favored for their compact size, high efficiency, and ability to handle heavy loads, making them ideal for the intricate movements required in humanoid robotics. The market is characterized by continuous innovation and development, with companies investing in research to enhance the performance and durability of these gear systems. As technology advances, the Global Humanoid Robotic Cycloidal Gearboxes Market is expected to expand, offering new opportunities for growth and development in the robotics industry.

One-stage Cycloidal Gearbox, Two-stage Cycloidal Gearbox in the Global Humanoid Robotic Cycloidal Gearboxes Market:

In the realm of the Global Humanoid Robotic Cycloidal Gearboxes Market, the distinction between one-stage and two-stage cycloidal gearboxes is significant, as each type serves different purposes and offers unique advantages. A one-stage cycloidal gearbox is designed to provide a single reduction stage, which means it reduces the speed of the input shaft to the output shaft in one step. This type of gearbox is typically used in applications where a moderate reduction ratio is sufficient. One-stage cycloidal gearboxes are known for their simplicity, compact design, and high efficiency. They are often used in humanoid robots where space is limited, and weight is a critical factor. The simplicity of the one-stage design also contributes to its reliability and ease of maintenance, making it a popular choice for many robotic applications. On the other hand, a two-stage cycloidal gearbox offers two reduction stages, providing a higher reduction ratio compared to a one-stage gearbox. This makes it suitable for applications that require more significant torque and slower output speeds. Two-stage cycloidal gearboxes are often used in humanoid robots that perform tasks requiring high precision and strength, such as lifting heavy objects or performing complex movements. The additional reduction stage allows for greater control and accuracy, which is essential in advanced robotic applications. Despite being more complex than one-stage gearboxes, two-stage cycloidal gearboxes are designed to maintain high efficiency and reliability. They are engineered to handle higher loads and provide smoother operation, which is crucial for the intricate and delicate tasks performed by humanoid robots. The choice between one-stage and two-stage cycloidal gearboxes in the Global Humanoid Robotic Cycloidal Gearboxes Market depends on the specific requirements of the application. Factors such as the desired reduction ratio, torque requirements, space constraints, and the complexity of the tasks to be performed all play a role in determining the most suitable gearbox type. As the market continues to evolve, manufacturers are focusing on developing gearboxes that offer the best balance of performance, efficiency, and reliability to meet the diverse needs of humanoid robotics. The ongoing advancements in technology and materials are also contributing to the development of more advanced cycloidal gearboxes, further enhancing their capabilities and expanding their applications in the robotics industry.

Lower Limb Joints, Lower Hip Area, Upper Limb Joints in the Global Humanoid Robotic Cycloidal Gearboxes Market:

The usage of Global Humanoid Robotic Cycloidal Gearboxes Market in areas such as lower limb joints, lower hip area, and upper limb joints is pivotal in enhancing the functionality and efficiency of humanoid robots. In the context of lower limb joints, cycloidal gearboxes play a crucial role in enabling smooth and precise movements, which are essential for tasks such as walking, running, and balancing. The high torque and compact design of cycloidal gearboxes make them ideal for use in the knee and ankle joints of humanoid robots, where space is limited, and precise control is necessary. These gearboxes allow robots to mimic human-like movements, providing stability and agility in various environments. In the lower hip area, cycloidal gearboxes are used to facilitate complex movements that require a combination of strength and flexibility. The hip joint is a critical component in humanoid robots, as it supports the weight of the robot and enables a wide range of motions. Cycloidal gearboxes provide the necessary torque and control to perform tasks such as bending, twisting, and rotating, which are essential for activities like climbing stairs or navigating uneven terrain. The ability to handle high loads and provide smooth operation makes cycloidal gearboxes an ideal choice for the lower hip area in humanoid robots. In the upper limb joints, cycloidal gearboxes are used to enhance the dexterity and precision of humanoid robots. The shoulder, elbow, and wrist joints require a high degree of control to perform tasks such as grasping, lifting, and manipulating objects. Cycloidal gearboxes provide the necessary torque and accuracy to execute these movements with precision, allowing humanoid robots to perform tasks that require fine motor skills. The compact design of cycloidal gearboxes also allows for a more streamlined and lightweight robotic arm, which is essential for maintaining balance and stability. The use of cycloidal gearboxes in the upper limb joints enables humanoid robots to perform a wide range of tasks, from simple object manipulation to complex assembly operations. Overall, the Global Humanoid Robotic Cycloidal Gearboxes Market plays a vital role in advancing the capabilities of humanoid robots. By providing the necessary torque, precision, and efficiency, cycloidal gearboxes enable robots to perform complex tasks with human-like agility and dexterity. As technology continues to evolve, the applications of cycloidal gearboxes in humanoid robotics are expected to expand, offering new opportunities for innovation and development in the field.

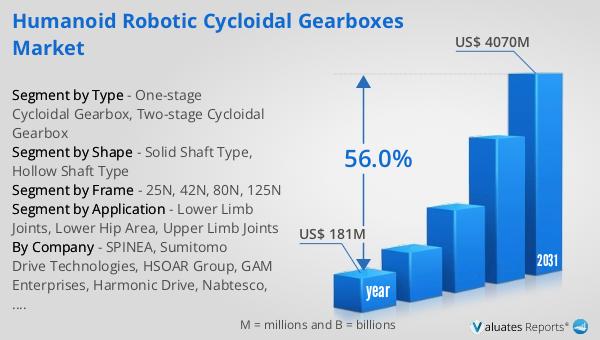

Global Humanoid Robotic Cycloidal Gearboxes Market Outlook:

The global market for Humanoid Robotic Cycloidal Gearboxes was valued at $181 million in 2024, with projections indicating a significant growth trajectory. By 2031, the market is expected to reach a revised size of $4,070 million, reflecting a robust compound annual growth rate (CAGR) of 56.0% during the forecast period. This remarkable growth underscores the increasing demand for advanced robotic systems and the critical role that cycloidal gearboxes play in enhancing the performance and efficiency of humanoid robots. The rapid expansion of this market can be attributed to several factors, including technological advancements, increased investment in research and development, and the growing adoption of humanoid robots across various industries. As businesses and consumers alike recognize the potential of humanoid robots to improve productivity and quality of life, the demand for reliable and efficient gear systems like cycloidal gearboxes continues to rise. This market outlook highlights the dynamic nature of the Global Humanoid Robotic Cycloidal Gearboxes Market and the opportunities it presents for innovation and growth. As the market evolves, companies are likely to focus on developing new and improved gear systems that meet the diverse needs of humanoid robotics, further driving the market's expansion.

| Report Metric | Details |

| Report Name | Humanoid Robotic Cycloidal Gearboxes Market |

| Accounted market size in year | US$ 181 million |

| Forecasted market size in 2031 | US$ 4070 million |

| CAGR | 56.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Shape |

|

| Segment by Frame |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SPINEA, Sumitomo Drive Technologies, HSOAR Group, GAM Enterprises, Harmonic Drive, Nabtesco, Tsuntien Precision Co., Ltd., Nidec Drive Technology America Corporation, Transmission Machinery Co., Ltd., Eppinger, Varitron Engineering (Taiwan) Co., Ltd., Shenzhen KOMO Innovation Robotics Technology Co., Ltd., Zhejiang Shuanghuan Driveline Co., Ltd., Chengdu Haoneng Technology Co., Ltd., Nantong Zhenkang Welding Electromachinery Co., Ltd., Ningbo ZhongDa Leader Intelligent Transmission Co Ltd, Guilin Fuda Co., Ltd., Jiangsu Pacific Precision Forging Co., Ltd., Landai Technology Group Corp., Ltd., Lumos Robotics, Guangdong Dongyi Network Technology CO.,Ltd, Jiangsu Tailong (Group) Reducer Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |