What is Global Portable Hydrogen Sulfide Gas Detector Market?

The Global Portable Hydrogen Sulfide Gas Detector Market refers to the industry focused on the production and distribution of portable devices designed to detect hydrogen sulfide (H₂S) gas. Hydrogen sulfide is a colorless gas known for its distinctive rotten egg smell, and it is highly toxic and flammable. These portable detectors are crucial for ensuring safety in various industrial environments where H₂S gas might be present. They are used to monitor air quality and alert users to dangerous levels of hydrogen sulfide, thereby preventing potential health hazards and accidents. The market for these detectors is driven by the need for safety in industries such as oil and gas, wastewater treatment, chemical manufacturing, and mining. As awareness of workplace safety increases and regulations become more stringent, the demand for reliable and efficient gas detection solutions continues to grow. These devices are typically compact, easy to use, and equipped with advanced sensors that provide real-time data, making them indispensable tools for workers in hazardous environments. The market is characterized by continuous technological advancements aimed at improving the sensitivity, accuracy, and durability of these detectors, ensuring they meet the evolving needs of various industries.

Electrochemical, Catalytic Combustion (CAT), Infrared (IR), Photoionization (PID), Semiconductor Oxide in the Global Portable Hydrogen Sulfide Gas Detector Market:

The Global Portable Hydrogen Sulfide Gas Detector Market encompasses several types of detection technologies, each with its unique advantages and applications. Electrochemical sensors are among the most common in portable H₂S detectors. They operate by using a chemical reaction to produce an electrical signal proportional to the concentration of hydrogen sulfide in the air. These sensors are highly sensitive and can detect low levels of H₂S, making them suitable for environments where even trace amounts of the gas can pose a risk. They are also known for their accuracy and reliability, although they may require regular calibration and maintenance to ensure optimal performance. Catalytic Combustion (CAT) sensors, on the other hand, detect hydrogen sulfide by oxidizing the gas on a catalytic surface, which generates heat and changes the resistance of the sensor. This change is then measured and converted into a gas concentration reading. CAT sensors are robust and can operate in harsh conditions, but they may not be as sensitive as electrochemical sensors, especially at lower concentrations of H₂S. Infrared (IR) sensors use infrared light to detect hydrogen sulfide. They work by measuring the absorption of specific wavelengths of light by the gas. IR sensors are highly stable and require less maintenance compared to other types, making them ideal for long-term monitoring. However, they can be more expensive and may not be as effective in detecting very low concentrations of H₂S. Photoionization Detectors (PID) use ultraviolet light to ionize gas molecules, including hydrogen sulfide, and measure the resulting current to determine gas concentration. PIDs are versatile and can detect a wide range of volatile organic compounds, but they may not be as selective for H₂S as other sensor types. Finally, Semiconductor Oxide sensors detect hydrogen sulfide by measuring changes in the electrical resistance of a metal oxide semiconductor material when exposed to the gas. These sensors are cost-effective and durable, but they may be less accurate and require frequent calibration. Each of these technologies offers distinct benefits and limitations, and the choice of sensor often depends on the specific requirements of the application, such as the desired sensitivity, operating environment, and budget constraints. As the market evolves, manufacturers continue to innovate and improve these technologies to enhance their performance and meet the growing demand for reliable gas detection solutions.

Oil & Gas, Wastewater Treatment, Chemical Industry, Mining & Metallurgy, Other in the Global Portable Hydrogen Sulfide Gas Detector Market:

The usage of Global Portable Hydrogen Sulfide Gas Detectors spans several critical industries, each with unique requirements and challenges. In the oil and gas sector, these detectors are essential for ensuring the safety of workers and preventing accidents. Hydrogen sulfide is a common byproduct of oil and gas extraction and processing, and its presence can pose significant health risks. Portable detectors allow workers to monitor H₂S levels in real-time, providing immediate alerts if concentrations exceed safe limits. This capability is crucial for preventing exposure and ensuring compliance with safety regulations. In wastewater treatment facilities, hydrogen sulfide is often produced during the decomposition of organic matter. Portable detectors are used to monitor air quality and protect workers from the toxic effects of H₂S, which can cause respiratory problems and other health issues. These devices help maintain a safe working environment and ensure that treatment processes are operating efficiently. The chemical industry also relies on portable hydrogen sulfide detectors to safeguard workers and facilities. H₂S is used in various chemical processes, and its accidental release can lead to hazardous situations. Detectors provide an early warning system, allowing for quick response and mitigation of potential risks. In the mining and metallurgy industries, hydrogen sulfide can be released during the extraction and processing of certain ores. Portable detectors are used to monitor air quality in mines and processing plants, protecting workers from exposure to toxic gases. These devices are particularly important in underground mining operations, where ventilation may be limited, and gas concentrations can quickly reach dangerous levels. Other industries, such as agriculture and food processing, may also encounter hydrogen sulfide in specific situations. Portable detectors provide a flexible and reliable solution for monitoring air quality and ensuring safety across a wide range of applications. The versatility and portability of these devices make them an invaluable tool for industries that require constant vigilance against the dangers of hydrogen sulfide gas. As safety standards continue to evolve and the demand for effective gas detection solutions grows, the use of portable hydrogen sulfide detectors is expected to expand, further enhancing workplace safety and environmental protection.

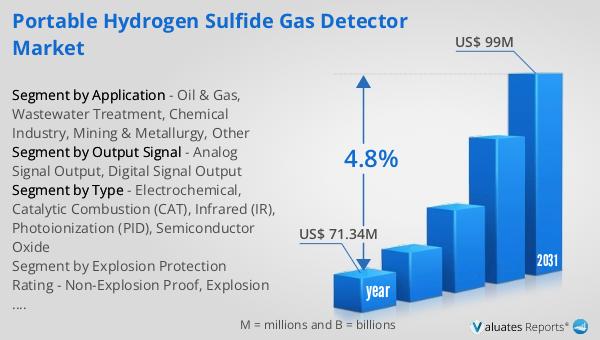

Global Portable Hydrogen Sulfide Gas Detector Market Outlook:

In 2024, the global market for Portable Hydrogen Sulfide Gas Detectors was valued at approximately $71.34 million. This market is anticipated to grow steadily, reaching an estimated value of $99 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.8% over the forecast period. The increasing demand for these detectors is driven by the need for enhanced safety measures in various industries, including oil and gas, chemical manufacturing, and wastewater treatment. As awareness of the dangers associated with hydrogen sulfide exposure grows, more companies are investing in reliable detection solutions to protect their workers and comply with stringent safety regulations. The market's expansion is also fueled by technological advancements that improve the accuracy, sensitivity, and durability of these devices, making them more effective and user-friendly. Manufacturers are continuously innovating to meet the evolving needs of different industries, ensuring that their products remain competitive in a dynamic market. As a result, the global Portable Hydrogen Sulfide Gas Detector Market is poised for significant growth, driven by the increasing emphasis on workplace safety and the adoption of advanced detection technologies.

| Report Metric | Details |

| Report Name | Portable Hydrogen Sulfide Gas Detector Market |

| Accounted market size in year | US$ 71.34 million |

| Forecasted market size in 2031 | US$ 99 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Sampling Method |

|

| Segment by Output Signal |

|

| Segment by Explosion Protection Rating |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Honeywell, Dräger, BEBUR, Industrial Scientific, Gasmet Technologies, Shenzhen Eranntex Electronics, SHENZHEN YUANTE TECHNOLOGY, Drksir, Xian Huafan Technology, Shenzhen Wanandi Technology, Hunan Tuoan Instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |