What is Global Phenolic Urethane Resin for Foundry Market?

Global Phenolic Urethane Resin for Foundry Market is a specialized segment within the broader industrial materials market, focusing on the production and application of phenolic urethane resins in foundries. These resins are essential in the casting process, where they serve as binders that hold sand molds together, ensuring the creation of precise and durable metal castings. The market is driven by the demand for high-quality castings in various industries, including automotive, aerospace, and construction. Phenolic urethane resins are favored for their excellent thermal stability, strength, and ability to produce smooth surface finishes, which are critical in manufacturing complex metal components. The market's growth is influenced by technological advancements in resin formulations, which enhance performance and environmental sustainability. Additionally, the increasing focus on reducing emissions and improving energy efficiency in foundries propels the adoption of these resins. As industries continue to seek innovative solutions for casting processes, the Global Phenolic Urethane Resin for Foundry Market is poised for steady expansion, driven by the need for high-performance materials that meet stringent quality and environmental standards.

Cold Box Resin, Self-Hardening Resin in the Global Phenolic Urethane Resin for Foundry Market:

Cold Box Resin and Self-Hardening Resin are two prominent types of resins used in the Global Phenolic Urethane Resin for Foundry Market, each offering unique benefits and applications. Cold Box Resin is a widely used binder system in the foundry industry, known for its ability to produce high-quality cores and molds with excellent dimensional accuracy. This resin system operates at room temperature, which simplifies the production process and reduces energy consumption. The cold box process involves mixing sand with a phenolic urethane resin and a catalyst, which hardens the mixture upon exposure to a gaseous curing agent. This method is highly efficient, allowing for rapid production cycles and the creation of complex shapes with smooth surface finishes. Cold Box Resins are particularly valued for their strength, thermal stability, and ability to produce castings with minimal defects, making them ideal for high-precision applications in industries such as automotive and aerospace. On the other hand, Self-Hardening Resin, also known as no-bake resin, is another critical component in the foundry market. This resin system is characterized by its ability to harden at room temperature without the need for external heat or curing agents. The self-hardening process involves mixing sand with a phenolic urethane resin and a hardener, which initiates a chemical reaction that solidifies the mixture over time. This method is advantageous for producing large and complex molds that require extended working times and greater flexibility in design. Self-Hardening Resins are known for their excellent strength, dimensional stability, and resistance to thermal shock, making them suitable for casting large metal components in industries such as construction and heavy machinery. Both Cold Box and Self-Hardening Resins play a crucial role in the foundry market, offering distinct advantages that cater to different production needs. Cold Box Resins are preferred for their speed and precision, making them ideal for high-volume production of intricate castings. In contrast, Self-Hardening Resins provide the flexibility and strength needed for larger, more complex molds, allowing for greater creativity and customization in casting designs. The choice between these resin systems depends on various factors, including the size and complexity of the casting, production volume, and specific industry requirements. The Global Phenolic Urethane Resin for Foundry Market continues to evolve, driven by advancements in resin technology and the growing demand for high-performance materials. Innovations in resin formulations have led to the development of environmentally friendly options that reduce emissions and improve sustainability in foundry operations. Additionally, the increasing emphasis on quality and precision in metal casting processes has spurred the adoption of advanced resin systems that enhance the overall efficiency and effectiveness of foundry operations. In conclusion, Cold Box Resin and Self-Hardening Resin are integral components of the Global Phenolic Urethane Resin for Foundry Market, each offering unique benefits that cater to different casting needs. As industries continue to seek innovative solutions for metal casting, these resin systems will play a vital role in shaping the future of the foundry market, driving advancements in quality, efficiency, and sustainability.

Cast Iron/Steel, Non-Ferrous Alloys, Other in the Global Phenolic Urethane Resin for Foundry Market:

The usage of Global Phenolic Urethane Resin for Foundry Market in areas such as Cast Iron/Steel, Non-Ferrous Alloys, and Other applications highlights the versatility and importance of these resins in various industrial sectors. In the casting of Cast Iron and Steel, phenolic urethane resins are essential for producing high-quality molds and cores that withstand the high temperatures and pressures involved in the casting process. These resins provide excellent thermal stability and strength, ensuring that the molds maintain their shape and integrity during casting. The result is precise and durable castings that meet the stringent quality standards required in industries such as automotive, aerospace, and heavy machinery. The ability of phenolic urethane resins to produce smooth surface finishes and intricate details further enhances their suitability for casting complex metal components. In the casting of Non-Ferrous Alloys, phenolic urethane resins offer similar benefits, providing the strength and stability needed to produce high-quality castings. Non-ferrous alloys, such as aluminum, copper, and zinc, are commonly used in industries that require lightweight and corrosion-resistant materials. Phenolic urethane resins enable the production of intricate and precise castings, ensuring that the final products meet the specific requirements of industries such as electronics, telecommunications, and consumer goods. The resins' ability to produce smooth surface finishes and intricate details is particularly valuable in these applications, where precision and aesthetics are critical. Beyond Cast Iron/Steel and Non-Ferrous Alloys, phenolic urethane resins are also used in other applications, demonstrating their versatility and adaptability. These resins are employed in the production of molds and cores for a wide range of materials, including specialty alloys and composite materials. The ability of phenolic urethane resins to provide strength, stability, and precision makes them suitable for casting a diverse array of components, from small, intricate parts to large, complex structures. This versatility is particularly valuable in industries that require customized solutions and innovative designs, such as construction, energy, and transportation. The use of phenolic urethane resins in these areas is driven by the need for high-performance materials that meet the demanding requirements of modern industries. As industries continue to evolve and seek innovative solutions for casting processes, the demand for phenolic urethane resins is expected to grow. The resins' ability to enhance the quality, efficiency, and sustainability of casting operations makes them an essential component of the Global Phenolic Urethane Resin for Foundry Market. In summary, the usage of Global Phenolic Urethane Resin for Foundry Market in Cast Iron/Steel, Non-Ferrous Alloys, and Other applications underscores the importance of these resins in various industrial sectors. Their ability to provide strength, stability, and precision makes them indispensable in the production of high-quality castings, meeting the specific requirements of diverse industries. As the demand for innovative and sustainable casting solutions continues to rise, phenolic urethane resins will play a crucial role in shaping the future of the foundry market.

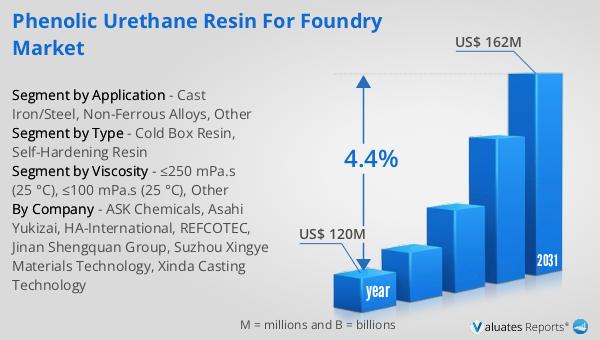

Global Phenolic Urethane Resin for Foundry Market Outlook:

The global market for Phenolic Urethane Resin for Foundry was valued at US$ 120 million in 2024, and it is anticipated to expand to a revised size of US$ 162 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.4% over the forecast period. This growth trajectory underscores the increasing demand for phenolic urethane resins in the foundry industry, driven by the need for high-quality and efficient casting solutions. The market's expansion is fueled by advancements in resin technology, which enhance performance and environmental sustainability, as well as the growing emphasis on reducing emissions and improving energy efficiency in foundry operations. As industries continue to seek innovative solutions for metal casting, the demand for phenolic urethane resins is expected to rise, contributing to the market's steady growth. The projected increase in market size reflects the resins' critical role in enhancing the quality, efficiency, and sustainability of casting processes, making them an essential component of the foundry industry. As the market evolves, phenolic urethane resins will continue to play a vital role in meeting the diverse needs of industries that rely on high-performance materials for casting operations.

| Report Metric | Details |

| Report Name | Phenolic Urethane Resin for Foundry Market |

| Accounted market size in year | US$ 120 million |

| Forecasted market size in 2031 | US$ 162 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Viscosity |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASK Chemicals, Asahi Yukizai, HA-International, REFCOTEC, Jinan Shengquan Group, Suzhou Xingye Materials Technology, Xinda Casting Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |