What is Global Dimethyltin Dineodecanoate Market?

The Global Dimethyltin Dineodecanoate Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of dimethyltin dineodecanoate, a chemical compound used primarily as a stabilizer in various industrial applications. This market is driven by the demand for high-performance stabilizers that enhance the durability and longevity of products, particularly in the plastics and polymers sectors. Dimethyltin dineodecanoate is valued for its ability to improve the heat stability of polyvinyl chloride (PVC) and other polymers, making it a crucial component in manufacturing processes where thermal stability is essential. The market is characterized by a steady growth trajectory, influenced by technological advancements and the increasing need for efficient and environmentally friendly stabilizers. As industries continue to seek materials that offer both performance and sustainability, the demand for dimethyltin dineodecanoate is expected to rise, reflecting broader trends in industrial innovation and environmental responsibility. The market's growth is also supported by regulatory frameworks that encourage the use of safer and more sustainable chemical compounds, further solidifying its role in the global chemical industry landscape.

Tin Content≥22%, Tin Content≥23% in the Global Dimethyltin Dineodecanoate Market:

In the Global Dimethyltin Dineodecanoate Market, the specification of tin content is a critical factor that influences the product's performance and application. Products with a tin content of ≥22% and ≥23% are particularly significant, as they denote the concentration of tin within the compound, which directly impacts its effectiveness as a stabilizer. A higher tin content generally correlates with enhanced stabilizing properties, making these products highly sought after in industries that require robust thermal stability. The ≥22% tin content variant is often used in applications where moderate stabilization is sufficient, providing a balance between performance and cost-effectiveness. This makes it an attractive option for manufacturers looking to optimize their production processes without incurring excessive costs. On the other hand, the ≥23% tin content variant is preferred in applications demanding superior stabilization, such as in high-temperature environments or where the longevity of the product is a critical consideration. This variant is particularly valued in the production of high-performance PVC products, where maintaining structural integrity under thermal stress is paramount. The choice between these two variants is largely determined by the specific requirements of the application, with manufacturers selecting the appropriate tin content based on factors such as operating conditions, desired product lifespan, and cost constraints. The availability of these variants allows for greater flexibility in product design and manufacturing, enabling companies to tailor their offerings to meet the diverse needs of their customers. Additionally, the differentiation in tin content also reflects broader trends in the market, where there is a growing emphasis on customization and specialization to cater to niche applications. As industries continue to evolve and demand more sophisticated materials, the importance of tin content in dimethyltin dineodecanoate products is likely to increase, driving further innovation and development in this market segment. This focus on tin content underscores the critical role that chemical composition plays in determining the performance and suitability of stabilizers, highlighting the need for ongoing research and development to enhance the capabilities of these compounds. As a result, the Global Dimethyltin Dineodecanoate Market is poised to continue its growth trajectory, supported by the increasing demand for high-performance stabilizers that can meet the rigorous demands of modern industrial applications.

Polyurethane, PVC, Other in the Global Dimethyltin Dineodecanoate Market:

The Global Dimethyltin Dineodecanoate Market finds its applications across various sectors, with significant usage in polyurethane, PVC, and other industries. In the polyurethane sector, dimethyltin dineodecanoate is utilized as a catalyst, playing a crucial role in the polymerization process. It helps in controlling the reaction rate, ensuring that the polyurethane products achieve the desired physical properties such as flexibility, durability, and resistance to environmental factors. This makes it an essential component in the production of foams, elastomers, and coatings, where precise control over the material properties is necessary to meet specific application requirements. In the PVC industry, dimethyltin dineodecanoate serves as a heat stabilizer, preventing the degradation of PVC during processing and extending the lifespan of the final product. Its ability to enhance the thermal stability of PVC makes it indispensable in the manufacturing of pipes, profiles, and films, where maintaining structural integrity under thermal stress is critical. The use of dimethyltin dineodecanoate in PVC applications is driven by the need for materials that can withstand high temperatures and harsh environmental conditions, ensuring the reliability and performance of PVC products in various applications. Beyond polyurethane and PVC, dimethyltin dineodecanoate is also used in other industries, where its stabilizing properties are leveraged to improve the performance and durability of products. This includes applications in the automotive, construction, and electronics sectors, where the demand for high-performance materials is continually increasing. The versatility of dimethyltin dineodecanoate in these diverse applications highlights its importance as a multifunctional stabilizer, capable of meeting the evolving needs of modern industries. As the demand for advanced materials continues to grow, the role of dimethyltin dineodecanoate in enhancing the performance and sustainability of products is expected to expand, driving further innovation and development in this market.

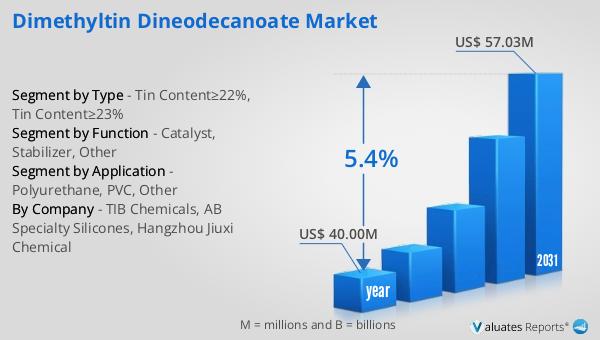

Global Dimethyltin Dineodecanoate Market Outlook:

The global market for Dimethyltin Dineodecanoate was valued at $40 million in 2024 and is anticipated to grow to a revised size of $57.03 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% during the forecast period. This growth trajectory underscores the increasing demand for dimethyltin dineodecanoate as a critical component in various industrial applications. The market's expansion is driven by the rising need for high-performance stabilizers that enhance the durability and longevity of products, particularly in the plastics and polymers sectors. As industries continue to seek materials that offer both performance and sustainability, the demand for dimethyltin dineodecanoate is expected to rise, reflecting broader trends in industrial innovation and environmental responsibility. The market's growth is also supported by regulatory frameworks that encourage the use of safer and more sustainable chemical compounds, further solidifying its role in the global chemical industry landscape. This positive market outlook highlights the importance of dimethyltin dineodecanoate as a versatile and effective stabilizer, capable of meeting the evolving needs of modern industries. As the demand for advanced materials continues to grow, the role of dimethyltin dineodecanoate in enhancing the performance and sustainability of products is expected to expand, driving further innovation and development in this market.

| Report Metric | Details |

| Report Name | Dimethyltin Dineodecanoate Market |

| Accounted market size in year | US$ 40.00 million |

| Forecasted market size in 2031 | US$ 57.03 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Function |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TIB Chemicals, AB Specialty Silicones, Hangzhou Jiuxi Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |